Sucker bowl taking device with laser detection control

A technology of laser detection and laser ranging, applied in the program control of sequence/logic controller, electrical program control, coin-operated equipment used to control the distribution of fluid/granular material from the container, etc., can solve the problem of clamping Problems such as instability, damage to the bowl, failure to fuse, etc., to achieve good suction freedom and precise controllability, centralized and stable rotation center of gravity, and small horizontal rotation radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

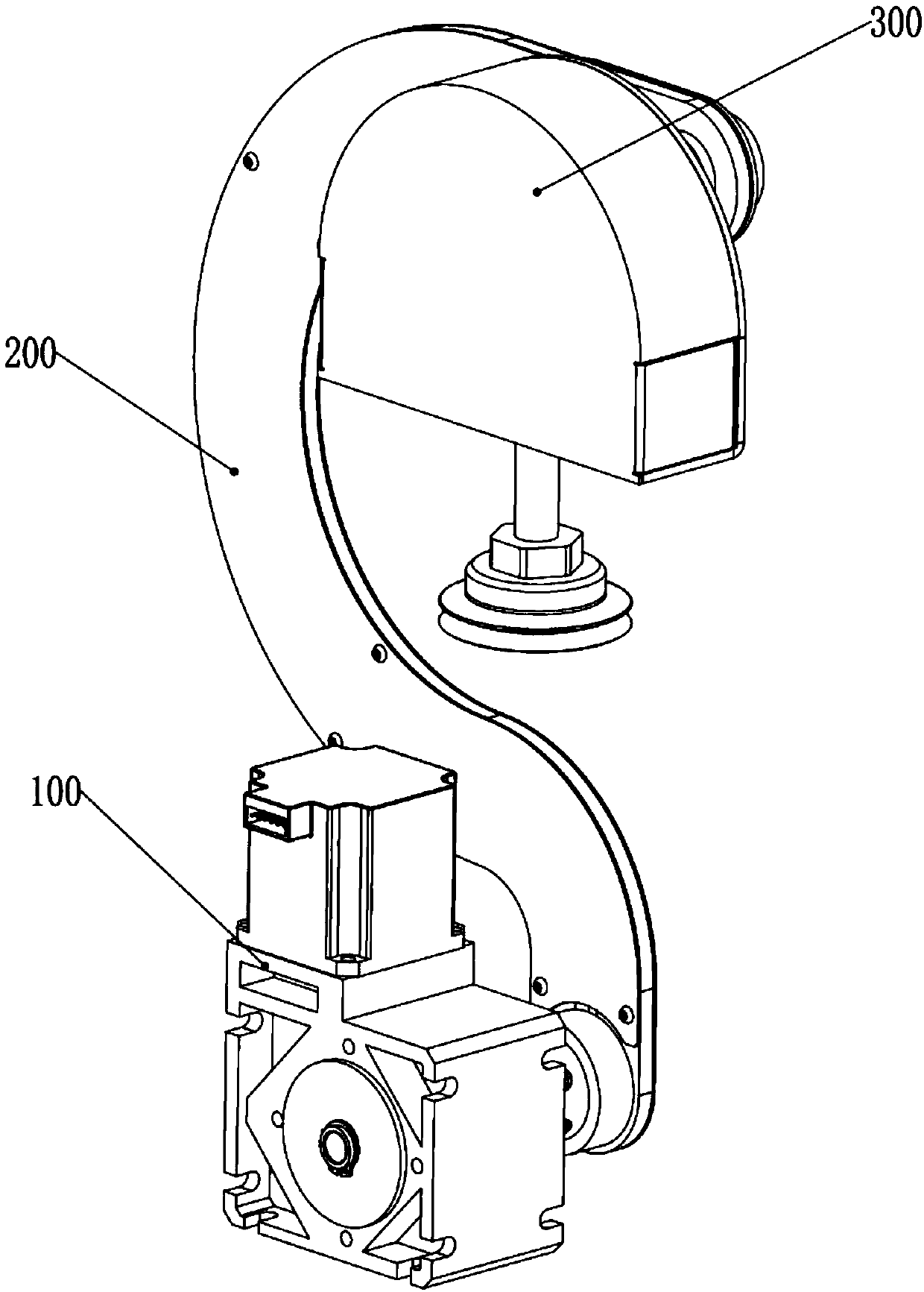

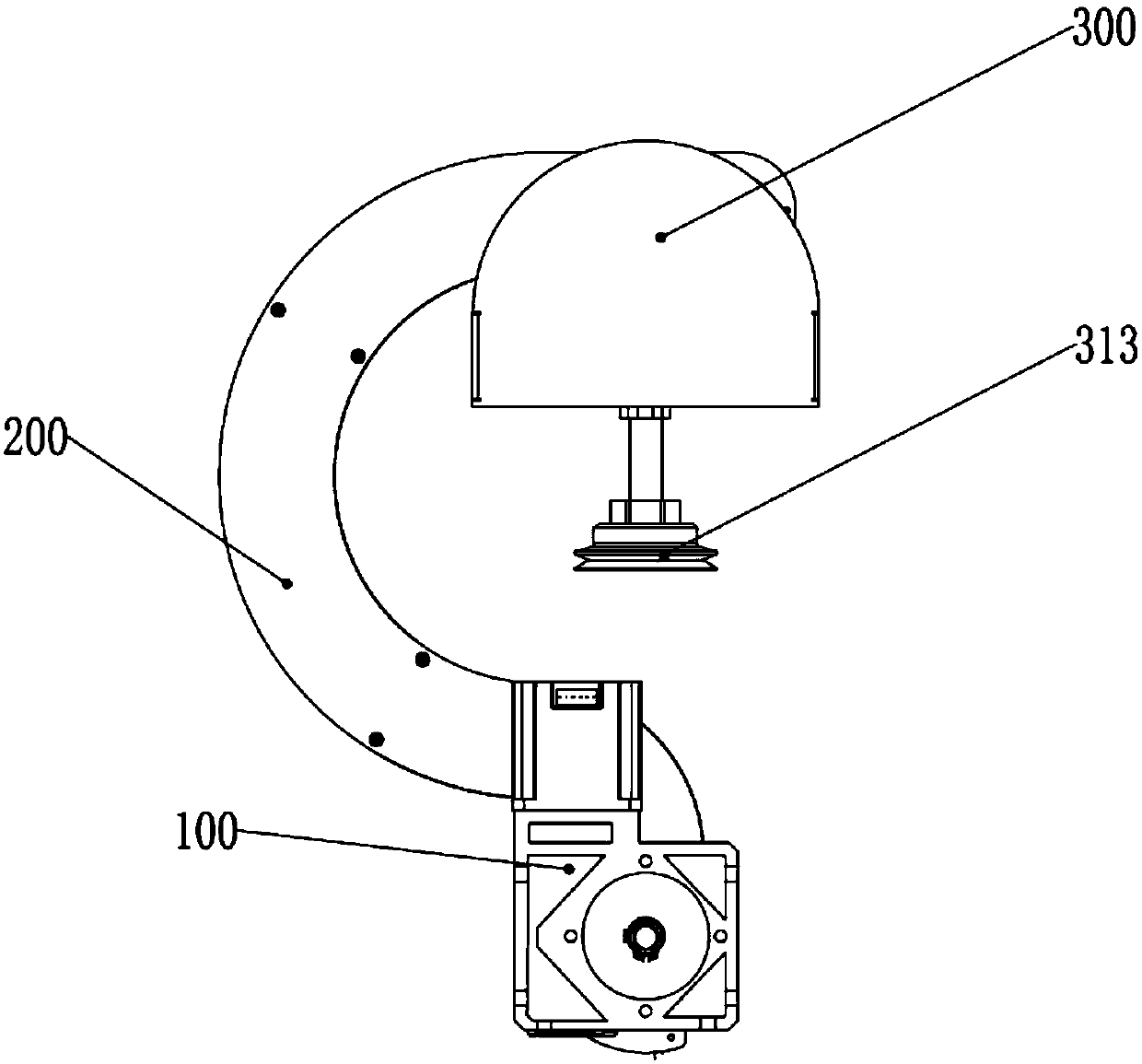

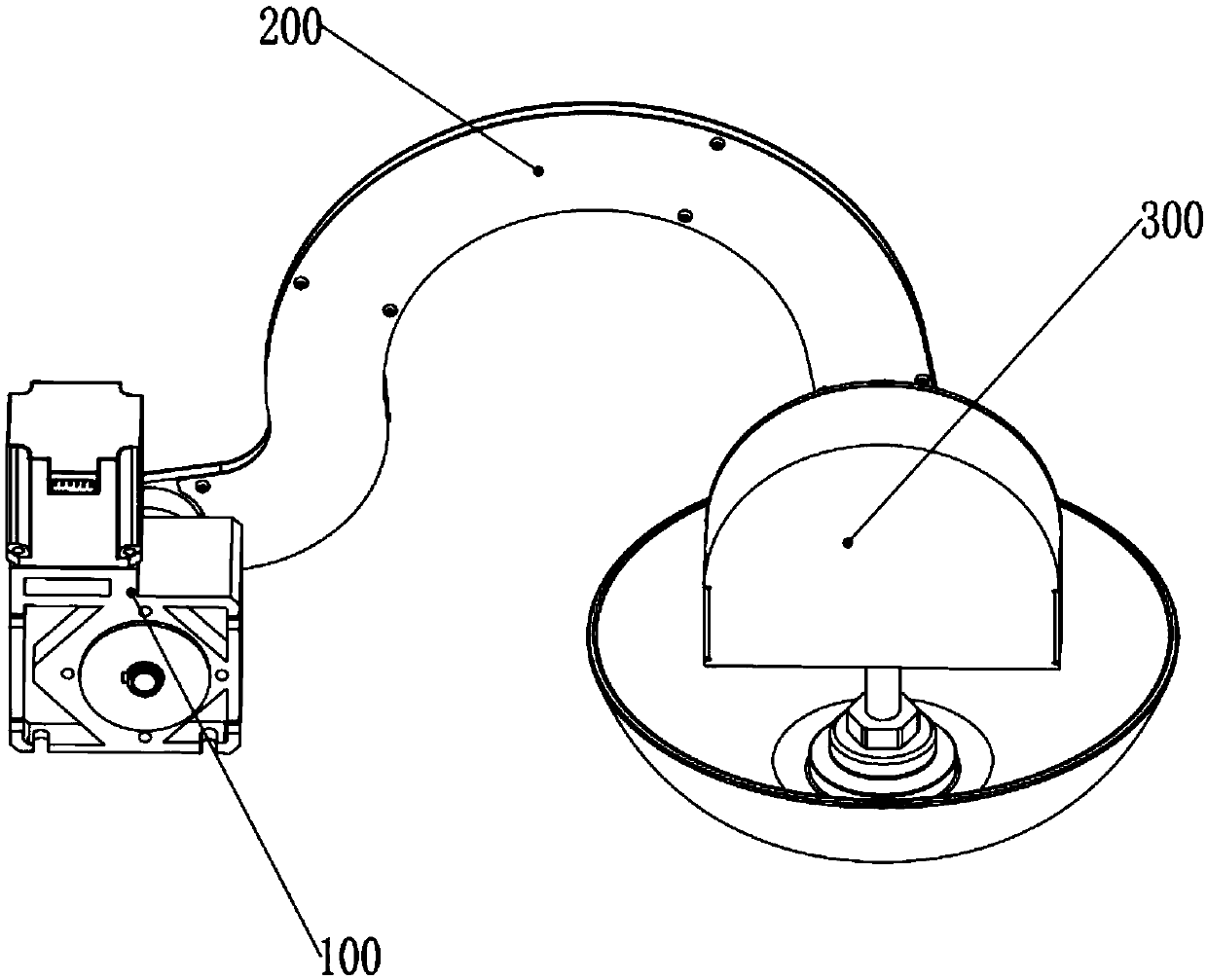

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] like Figure 1-4 As shown, a suction cup bowl picking device provided with laser detection control includes: a control box assembly 300, a swing arm assembly 200 and a motor assembly 100; the swing arm assembly 200 includes a swing arm body 210, and the swing arm body The lower end of 210 is a driving section 211, and the upper end is a driven section 212; the driven section 212 is provided with a swing bearing 214; the motor assembly 100 is provided with a swing motor 110; the control box assembly 300 includes: a control box housing 310 , a swing shaft 311, a vacuum pump 312 and a suction cup operating end; one end of the swing shaft 311 is connected to one side of the control housing, and the other end passes through the swing bearing 214 transversely; one end of the suction cup operating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com