Patents

Literature

39results about How to "Good precision control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for slide guiding drilling well control with adaptability

ActiveCN108227495AHigh control precisionGood precision controlSafety arrangmentsAdaptive controlControl systemDrilling system

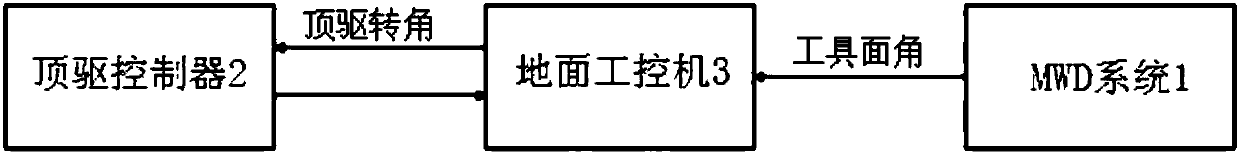

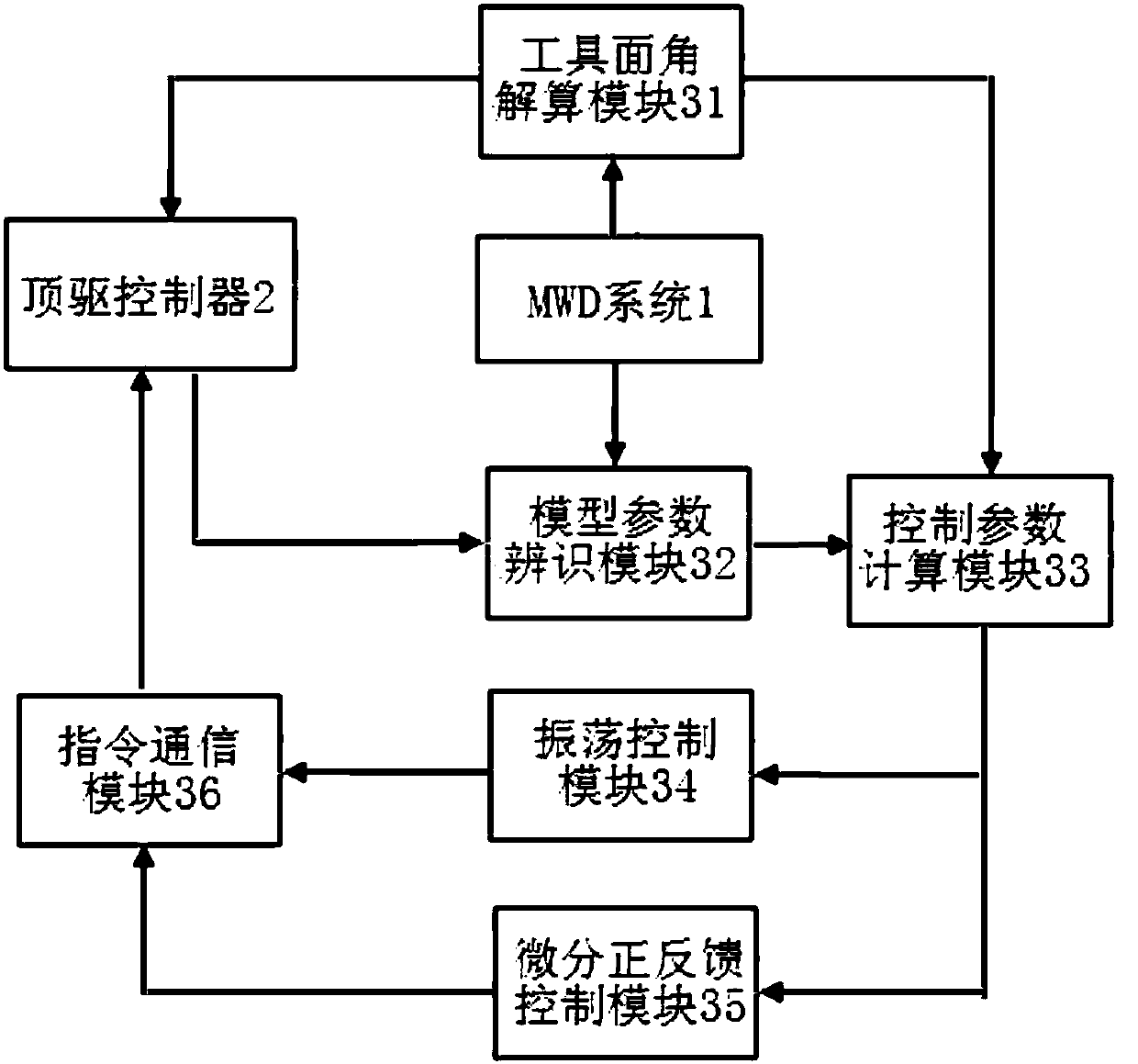

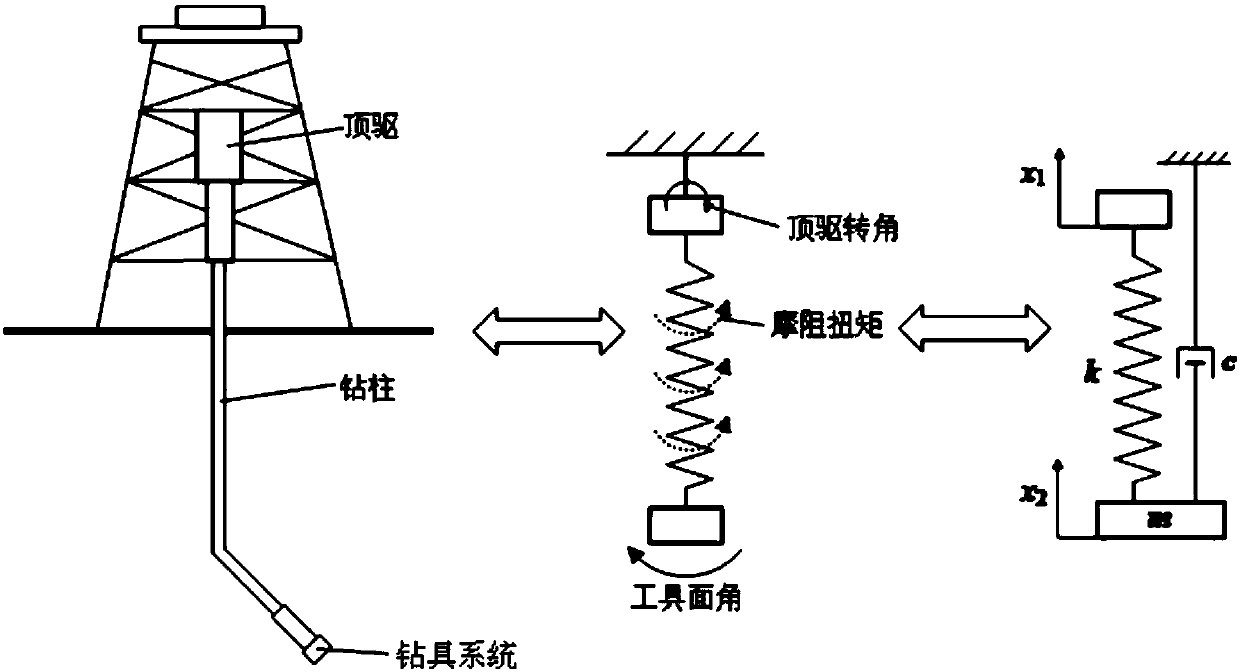

The present invention relates to a system and a method for slide guiding drilling well control with adaptability. The slide guiding drilling well control system comprises an MWD system, a top drive controller and a ground industrial control computer. The MWD system is configured to measure a tool face angle of a drilling system in a slide guiding drilling well in real time and send the tool face angle to the ground industrial control computer; the top drive controller is configured to control the rotation of a top drive in the slide guiding drilling well and perform real-time feedback of a corresponding top drive rotating angle to the ground industrial control computer; and the ground industrial control computer is configured to calculate an expected tool face angle and an expected top drive rotating angle in real time according to the tool face angle planned according to a well track, the measured tool face angle in real time and the top drive rotating angle with real-time feedback and send the expected tool face angle and the expected top drive rotating angle to the top drive controller, and the top drive controller controls the rotation of the top drive in the slide guiding drilling well according to the expected tool face angle and the expected top drive rotating angle so as to achieve adaptive control of the tool face angle of the drilling system in the slide guiding drilling well. The system and the method for slide guiding drilling well control with adaptability can be widely applied in the slide guiding drilling well field.

Owner:CHINA NAT OFFSHORE OIL CORP +2

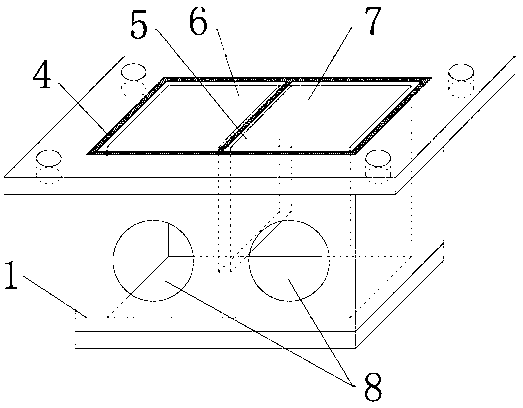

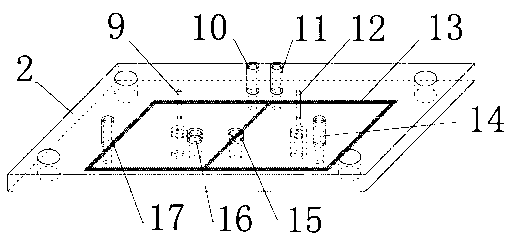

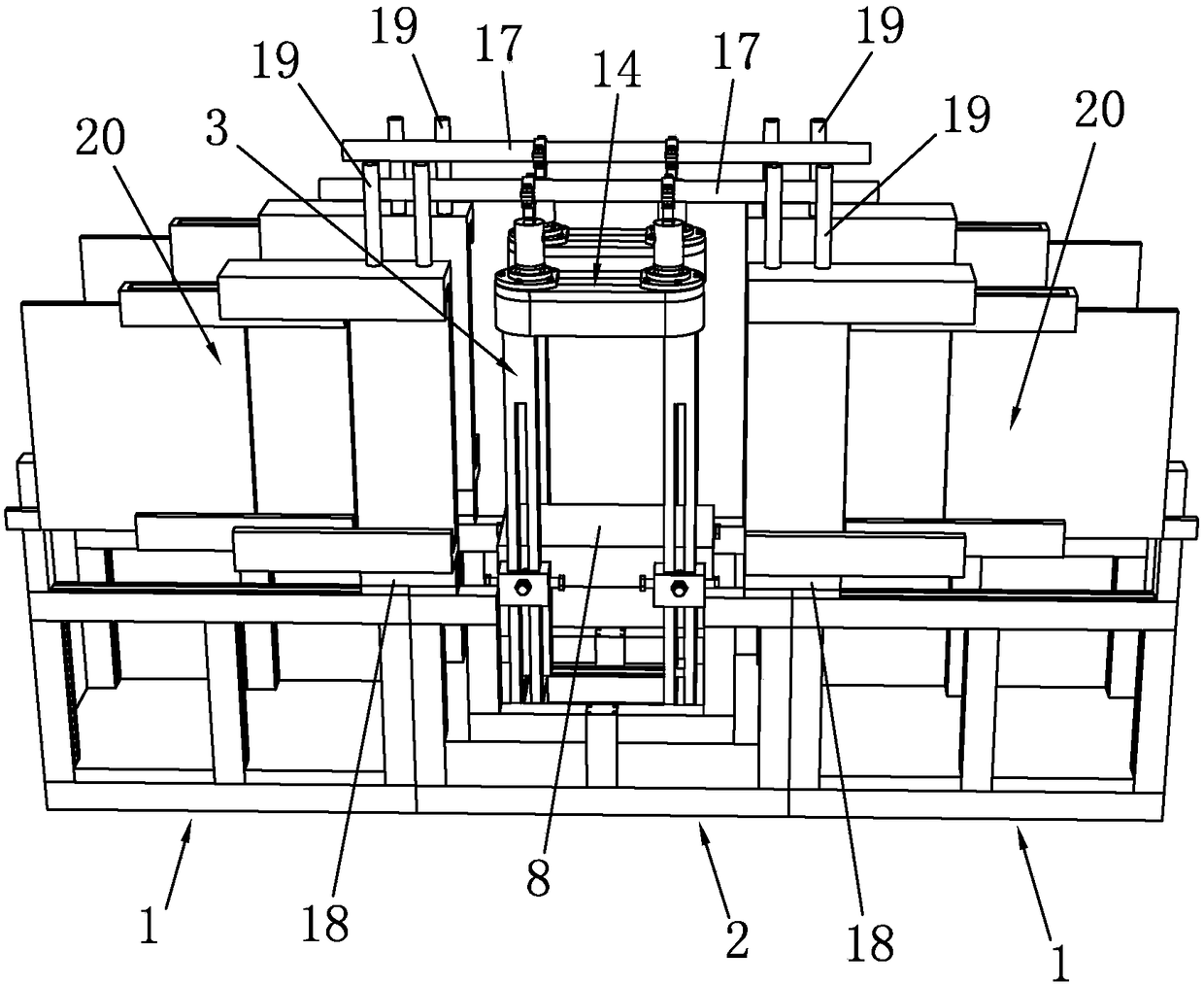

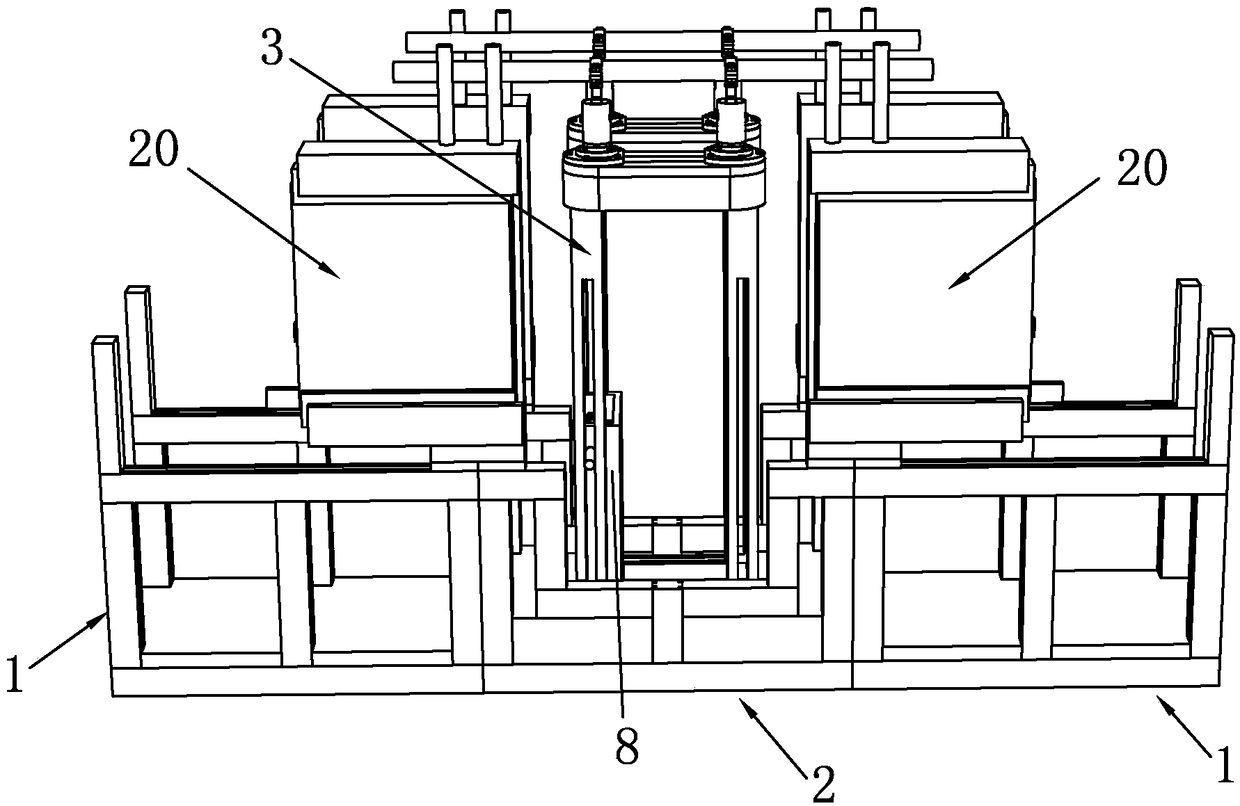

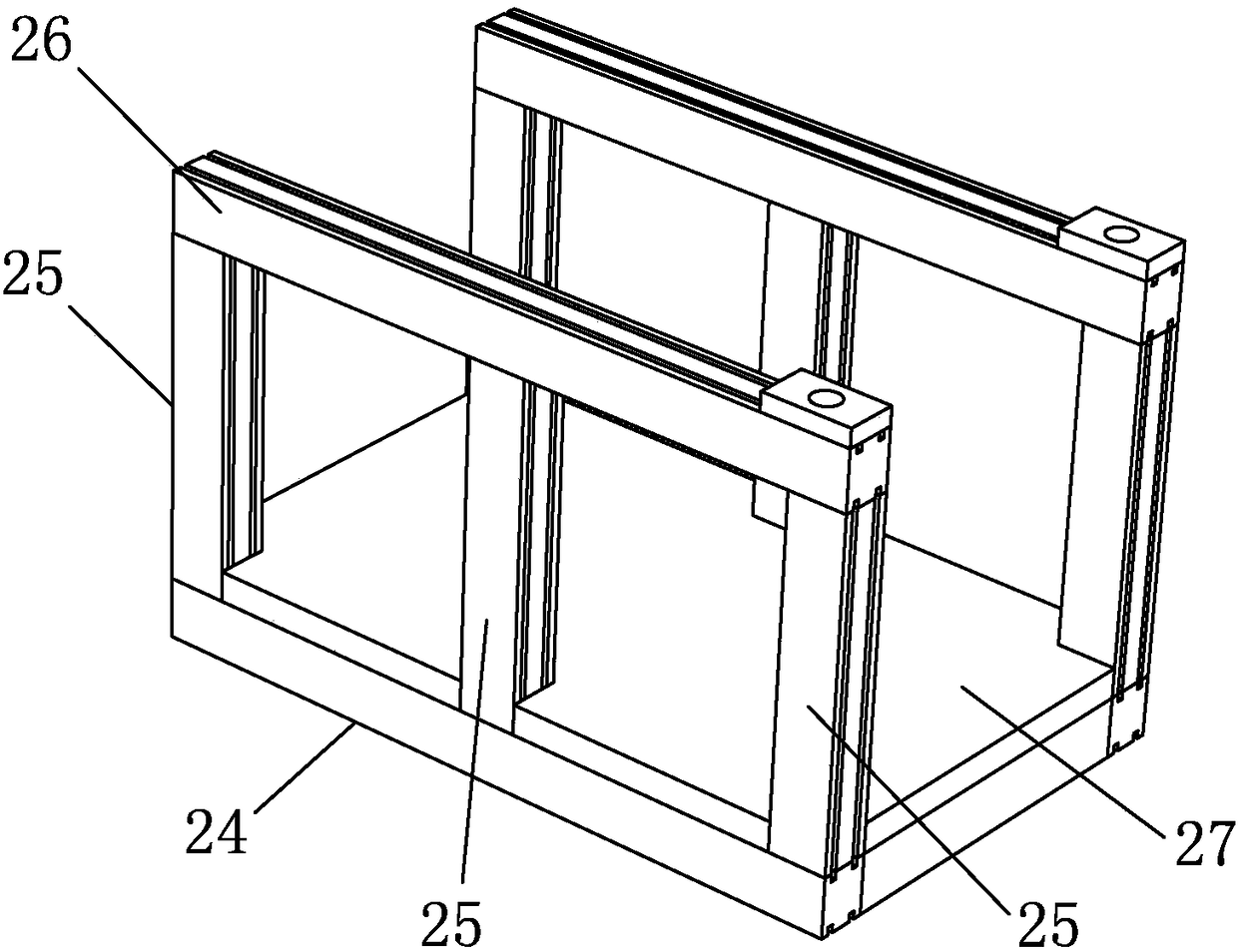

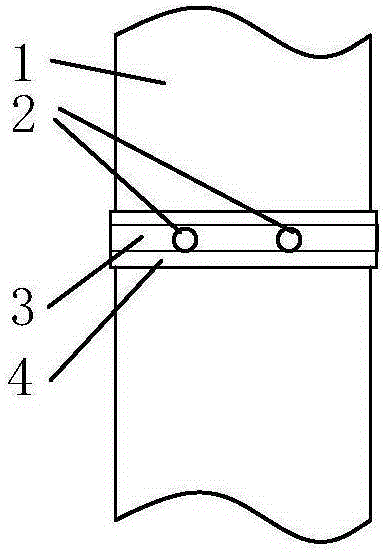

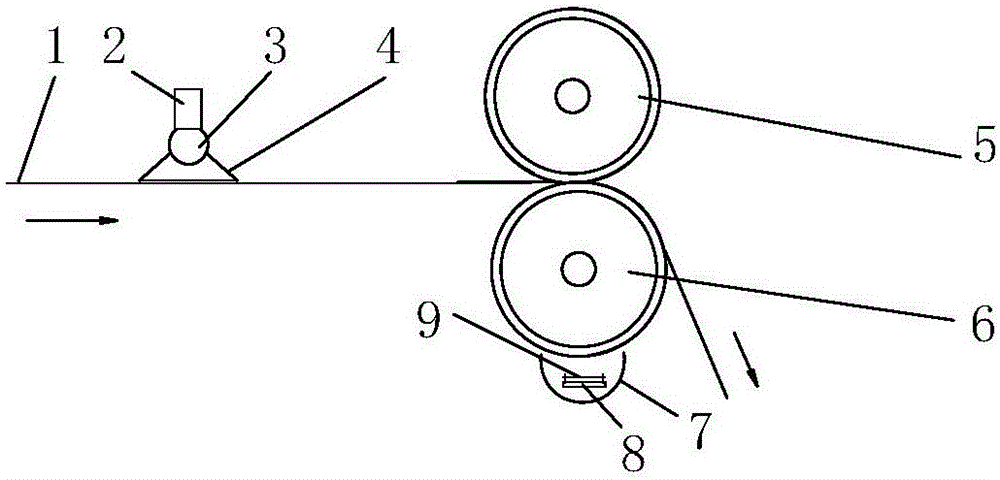

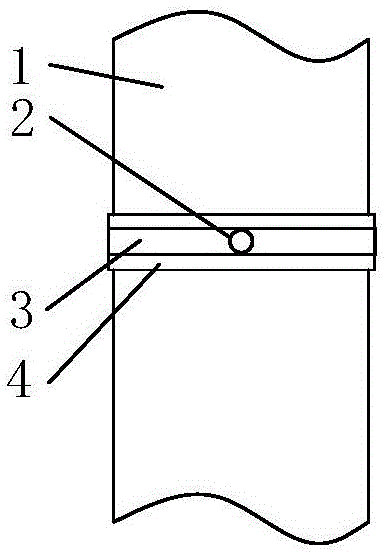

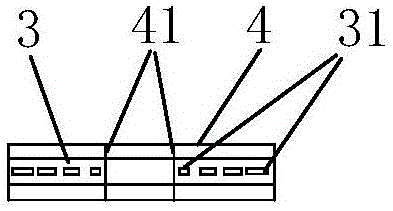

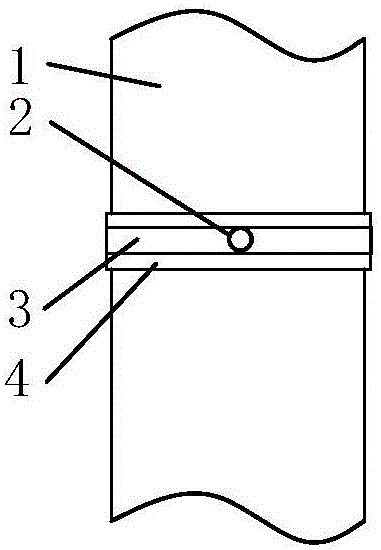

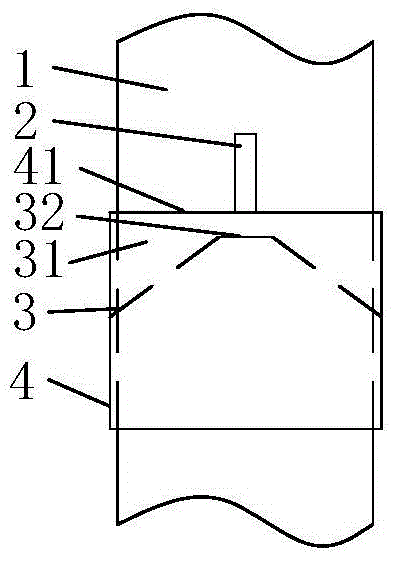

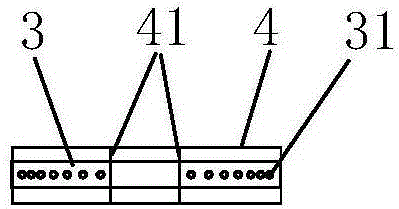

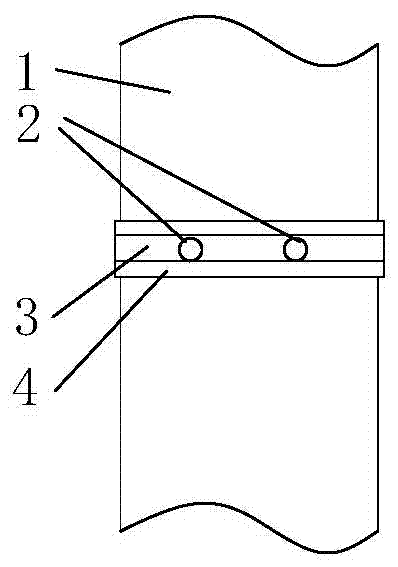

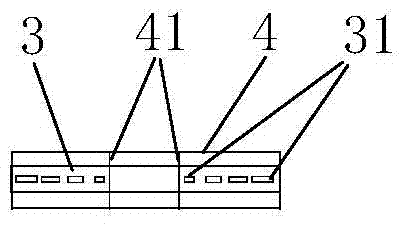

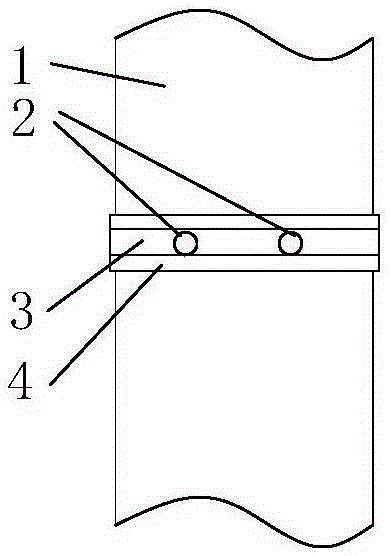

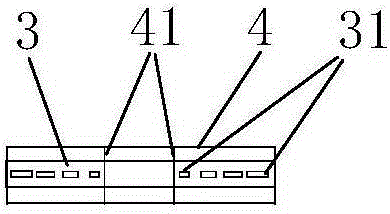

Double-chamber and double-window electrolytic tank for electrochemically preparing gases

InactiveCN103074638AGood precision controlEffective isolationCellsEnergy inputChemical physicsEngineering

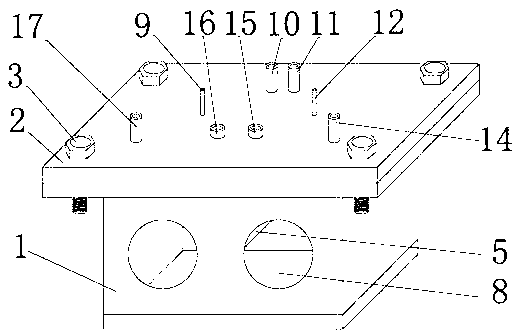

The invention belongs to the technical field of electrochemical and photo-electrochemical experimental research and in particular relates to a double-chamber and double-window electrolytic tank for electrochemically preparing gases. The problem that in the prior art, experimental results are affected by the gas mixing generated in the reaction is solved. In order to solve the problem of the prior art, the technical scheme provided by the invention is as follows: the double-chamber and double-window electrolytic tank for electrochemically preparing the gases comprises a reaction tank and a cover plate, wherein a partition plate is arranged in the reaction tank; the space in the reaction tank is divided into a working electrode reaction chamber and an auxiliary electrode reaction chamber through the partition plate; and a space is formed between the lower edge of the partition plate and the bottom of the reaction tank. According to the invention, effective gas insulation is formed on the surfaces of a working electrode and the auxiliary electrode, so that the accuracy of the experimental result is conveniently controlled; and the double-chamber and double-window electrolytic tank for electrochemically preparing the gases, provided by the invention, has the advantages of simple and compact structure, easiness in operation and practical function.

Owner:NORTHWEST UNIV(CN)

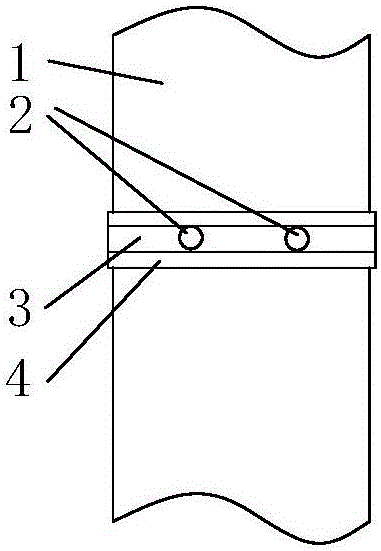

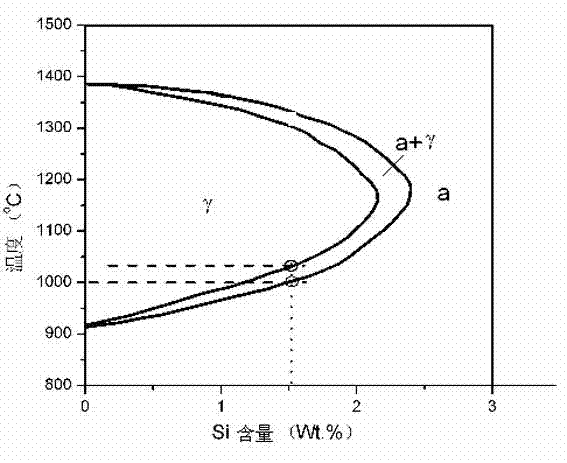

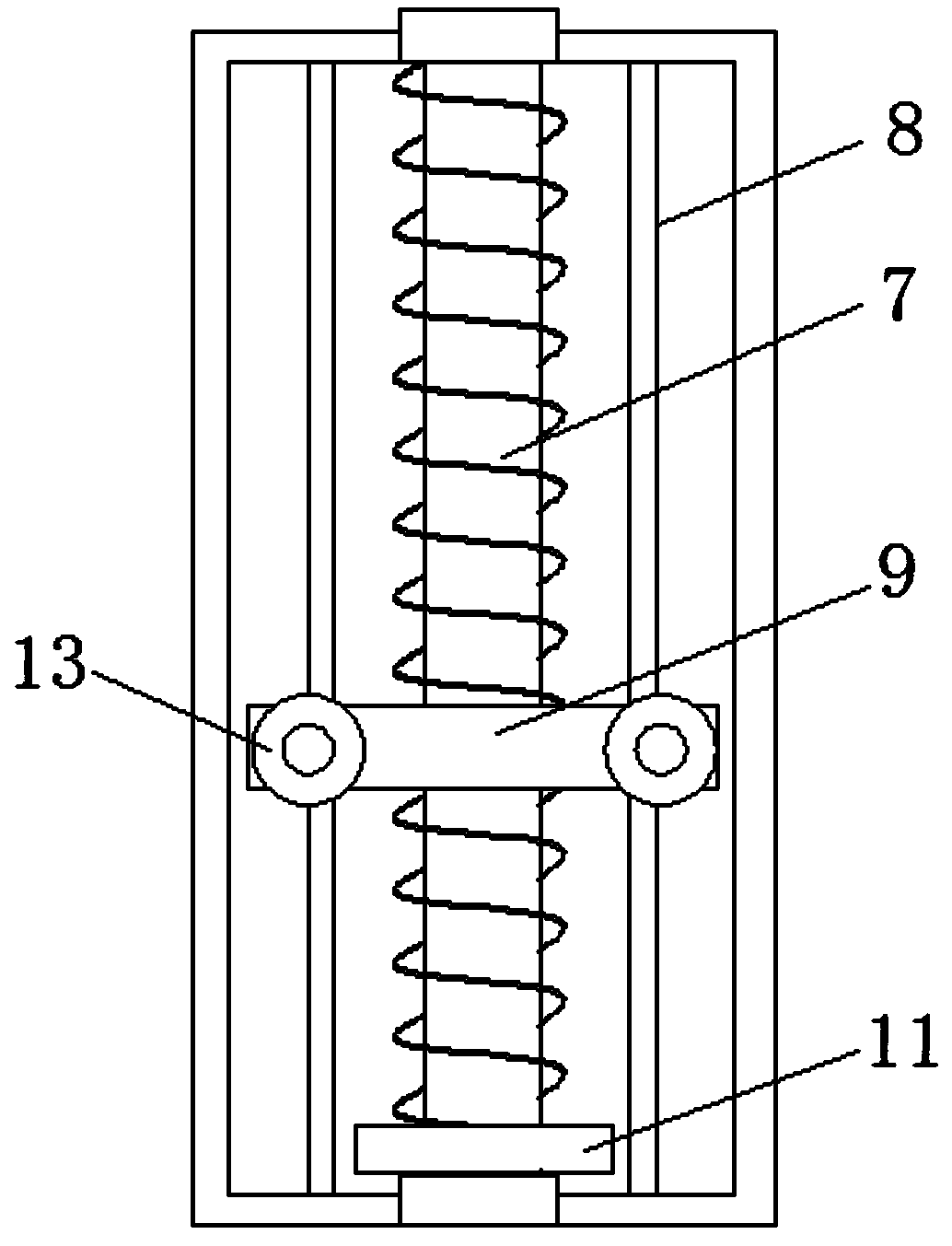

Hanging basket structure for constructional engineering and mounting method thereof

ActiveCN108385959APrevent looseningEasy to passBuilding material handlingScaffold accessoriesEngineeringHanging basket

The invention discloses a hanging basket structure for constructional engineering and a mounting method thereof. The structure comprises a first suspension platform and a second suspension platform, wherein a lifting frame is arranged in the second suspension platform; the lifting frame comprises a lifting platform and a lifting rod; the lifting rod is provided with a butted-joint rod; the butted-joint rod is connected with a working table; a traction adjustment mechanism is arranged at the top end of the lifting rod; the traction adjustment mechanism comprises an adjusting base and two adjusting rods; a traction rod is arranged between the adjusting rods; a mounting block is provided with a connecting rod; the connecting rod is provided with a protection device. The mounting method comprises the following steps: a, manufacturing the first suspension platform and the second suspension platform; b, mounting the lifting frame; c, mounting the working table; d, mounting the protection device; e, mounting the traction adjustment mechanism. According to the hanging basket structure for constructional engineering disclosed by the invention, steel components are conveniently delivered byconstruction personnel, so that the phenomenon that a hanging hook for hanging the steel components contacts with the hanging basket structure is avoided, the lifting stability of the hanging basket structure can be enhanced, and simultaneously, the fastness of the whole device is improved, and the security is improved.

Owner:段学治

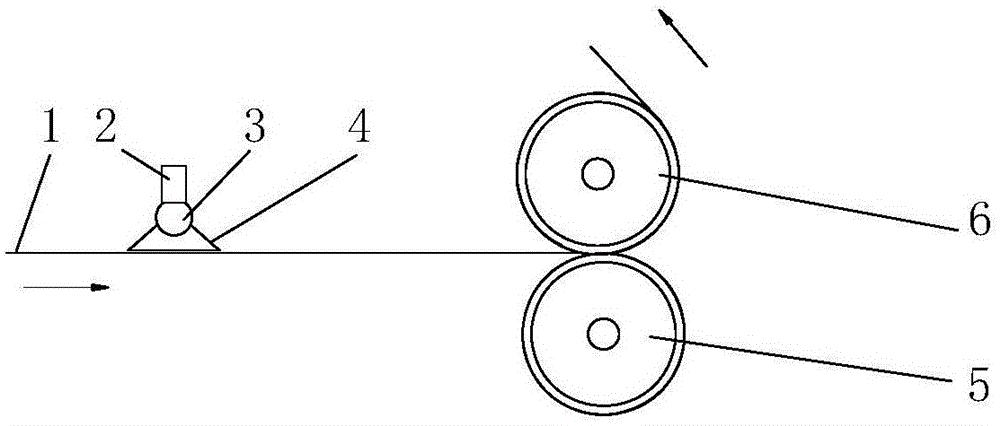

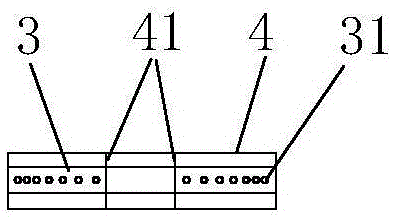

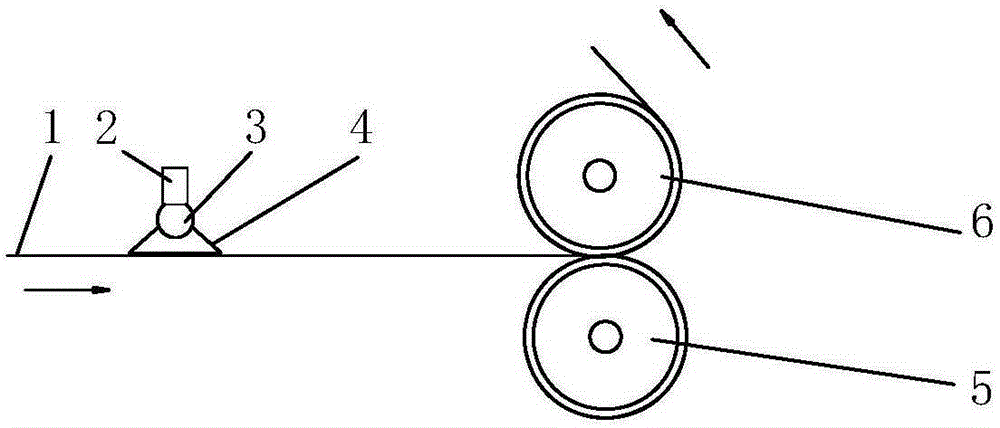

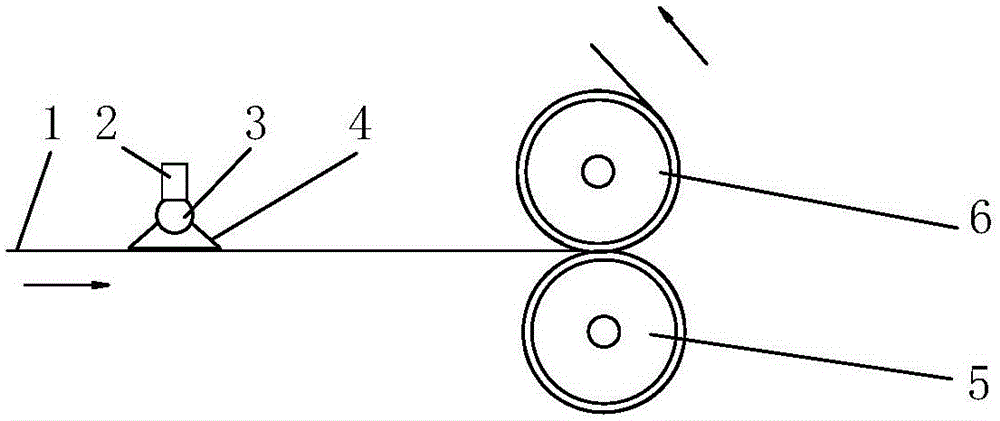

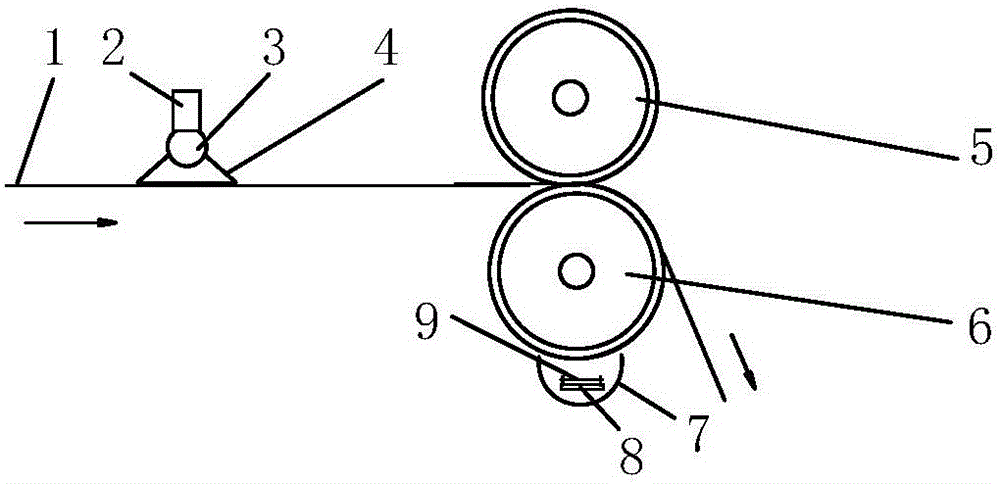

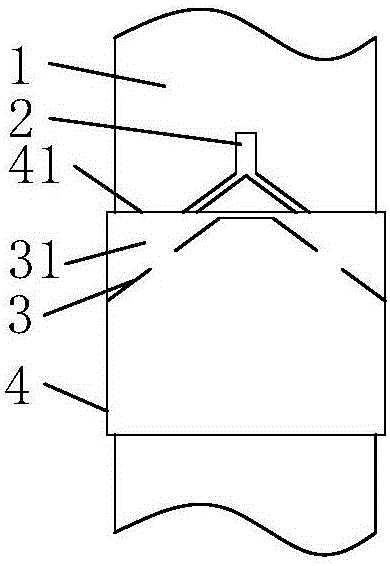

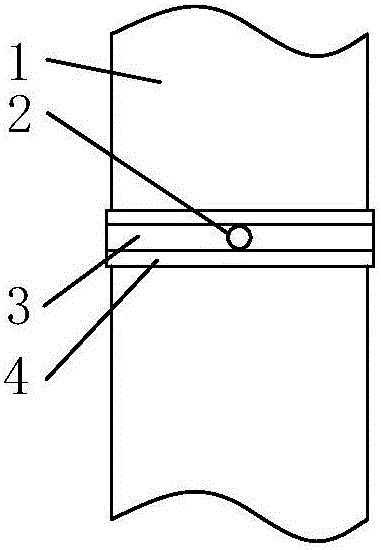

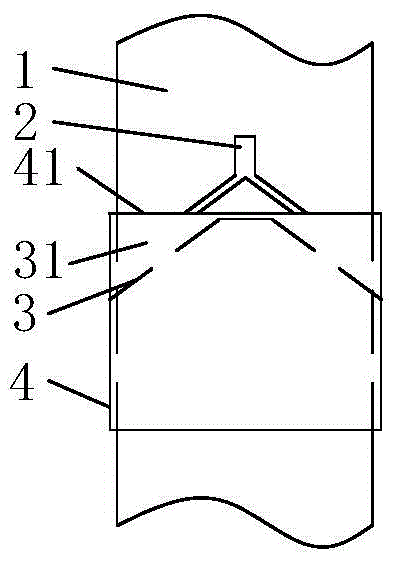

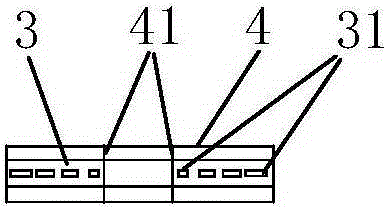

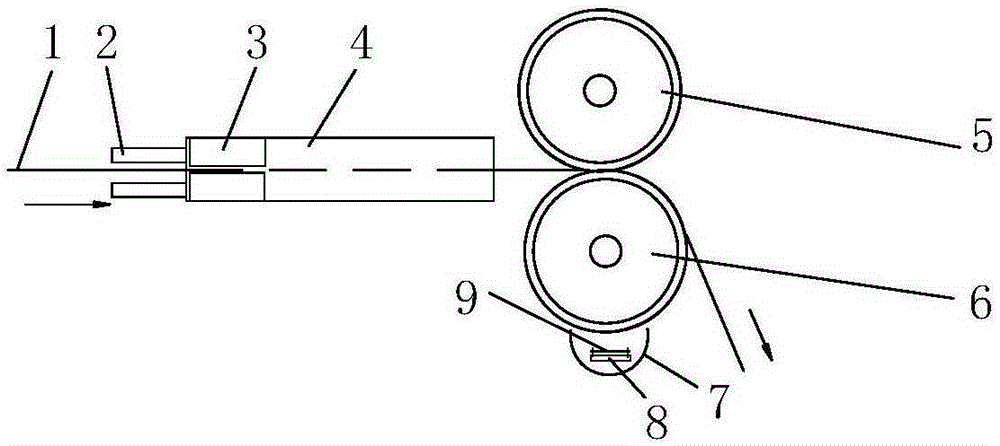

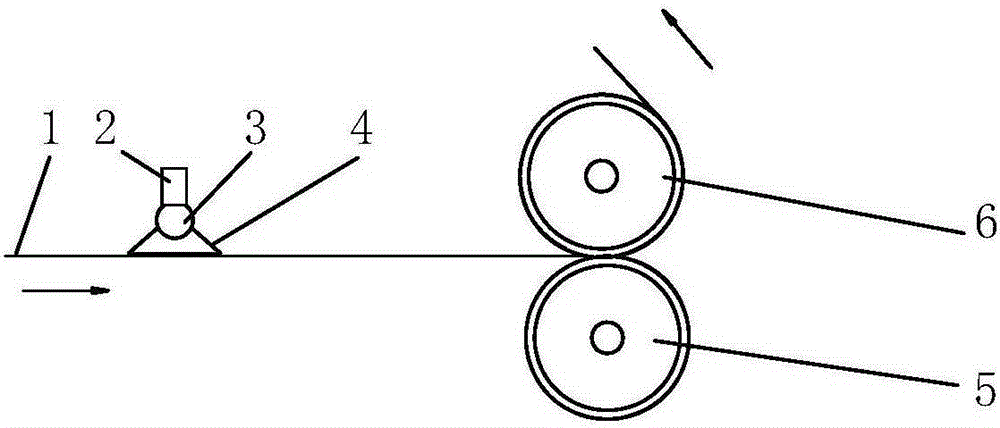

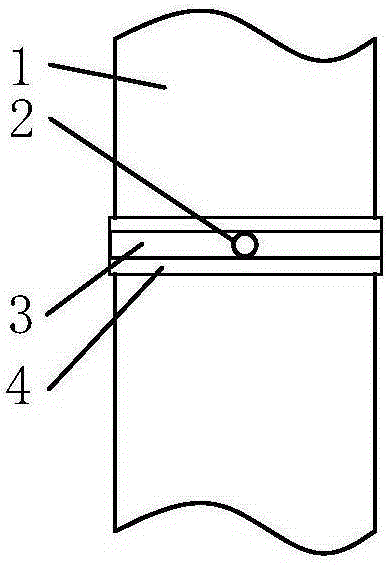

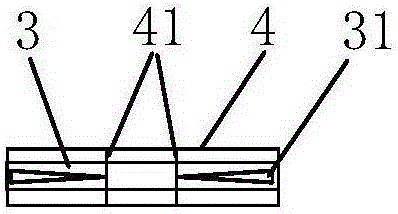

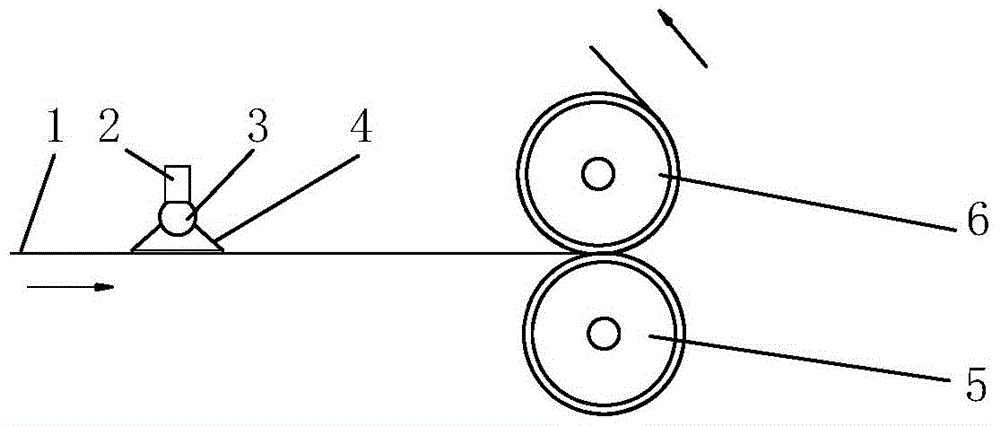

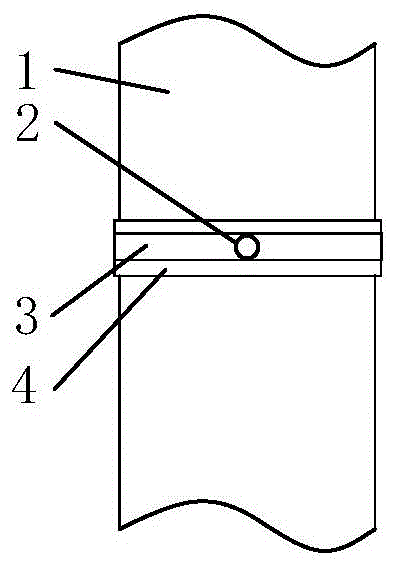

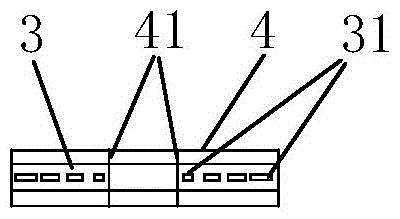

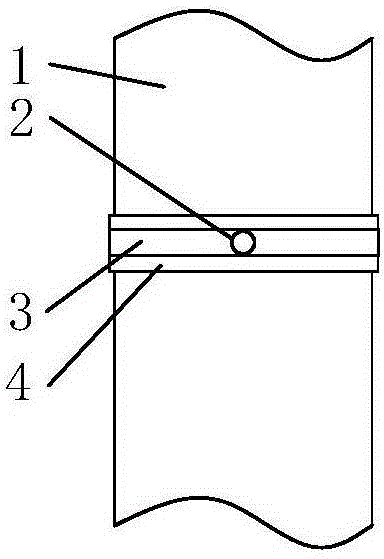

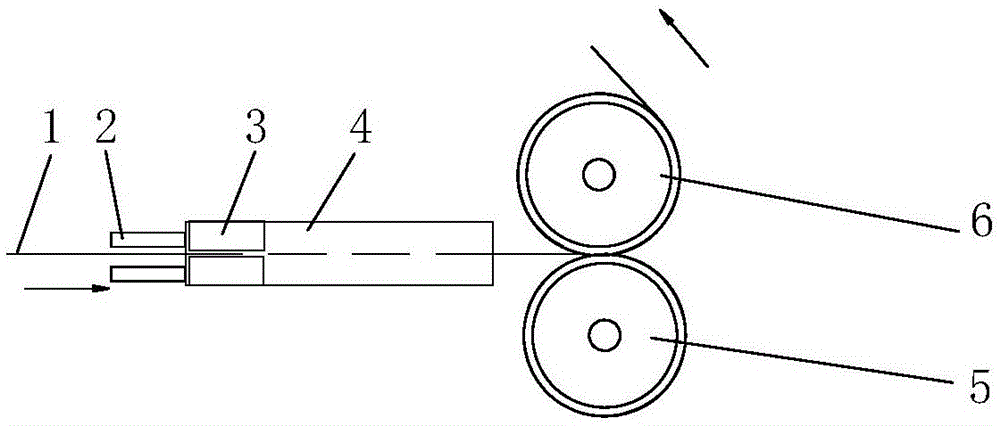

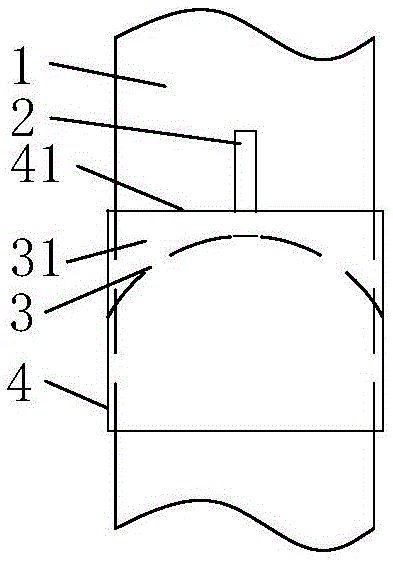

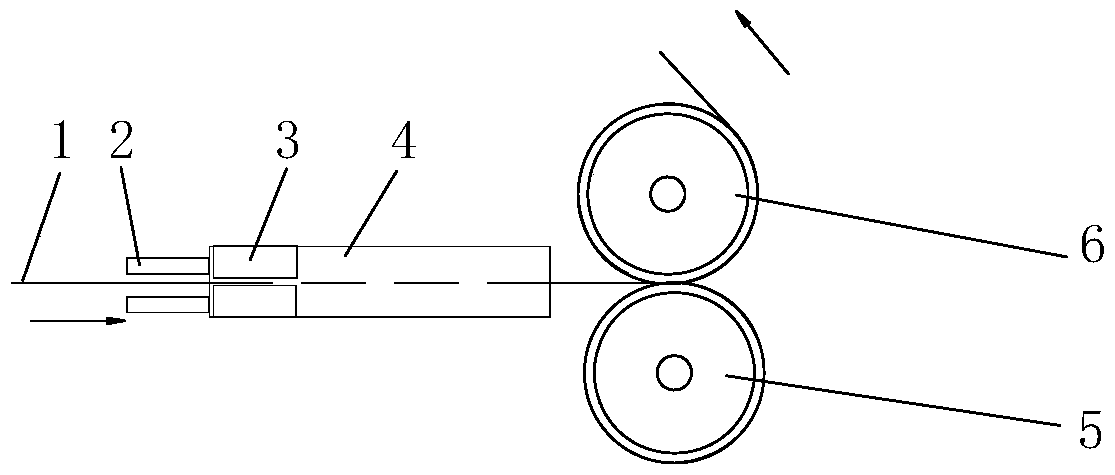

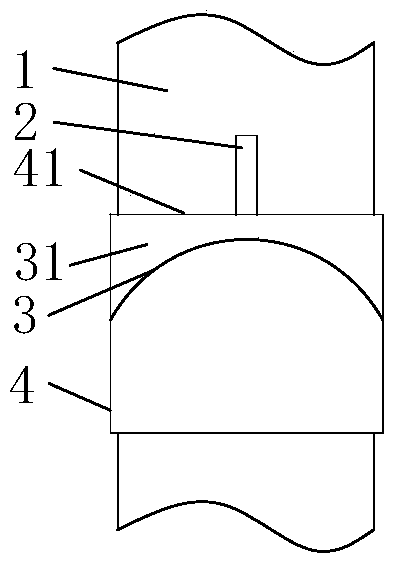

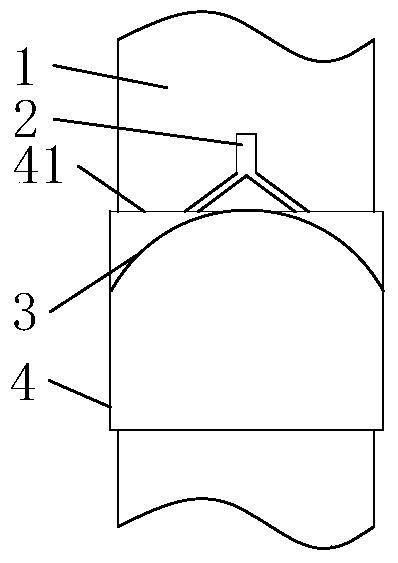

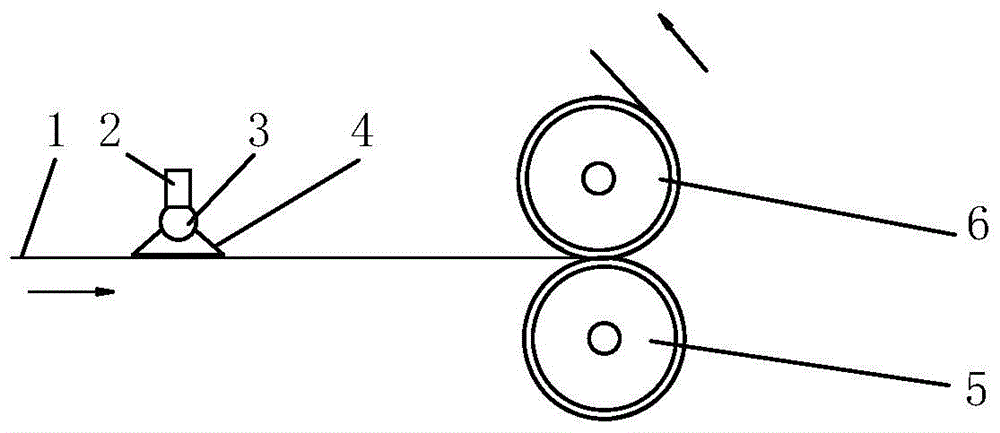

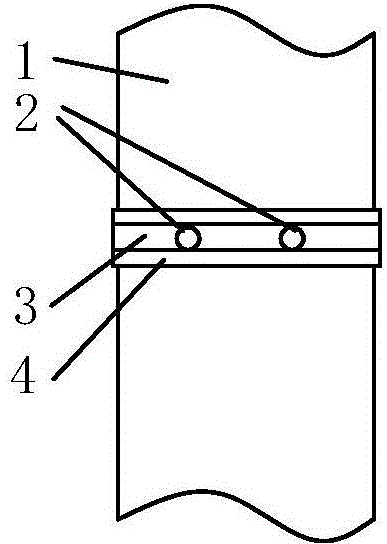

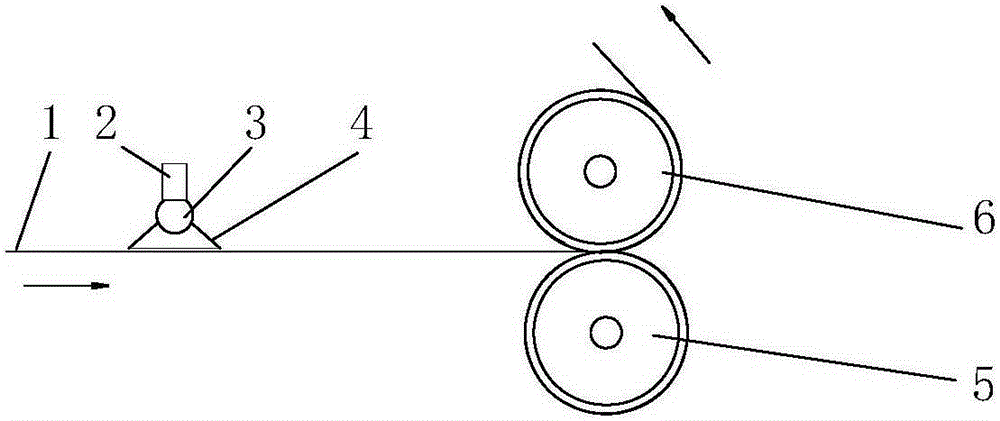

Heating roller for tanning ironing equipment

InactiveCN105064057AReasonable structureLow costTextile treatment by spraying/projectingTextile shapingPulp and paper industryHigh pressure

The invention discloses a heating roller for tanning ironing equipment. The heating roller comprises a heating roller body. The heating roller body is composed of a roller ring, two roller end faces and a roller shaft. The roller shaft is installed on a machine frame through a bearing. High-temperature oil in the heating roller body is communicated with a heating oil tank through an oil pump. The heating roller further comprises a fence ring which is composed of multiple circumferential strips with the same width and length and at least two axial strips. The fence ring is tightly attached to the inner wall of the roller ring. The distance between the circumferential strips close to the two ends of the roller ring is larger than the distance between the circumferential strips close to the center of the roller ring. The distance gradually changes. The fence ring blocks the roller ring from absorbing heat. The temperature of the positions close to the two ends of the roller ring is high. The position close to the center of the roller ring is low. The temperature gradually changes. The center of the roller ring has a certain distance J; in the distance J, the distances between the circumferential strips are equal, and the temperature of the corresponding position in the center of the roller ring is uniform. The heating roller has the advantages of saving heat energy and water, achieving high-temperature high-pressure shaping and being accurate in control and good in effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

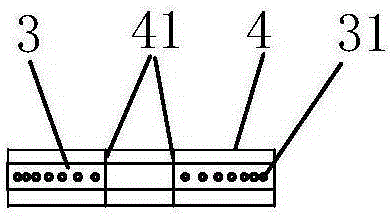

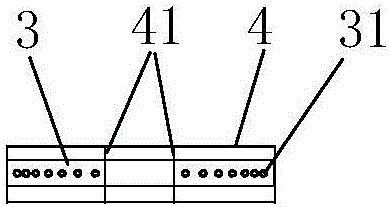

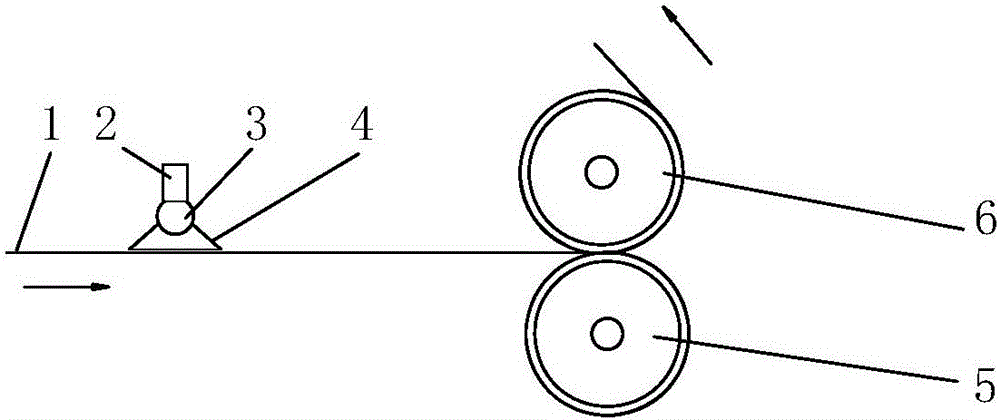

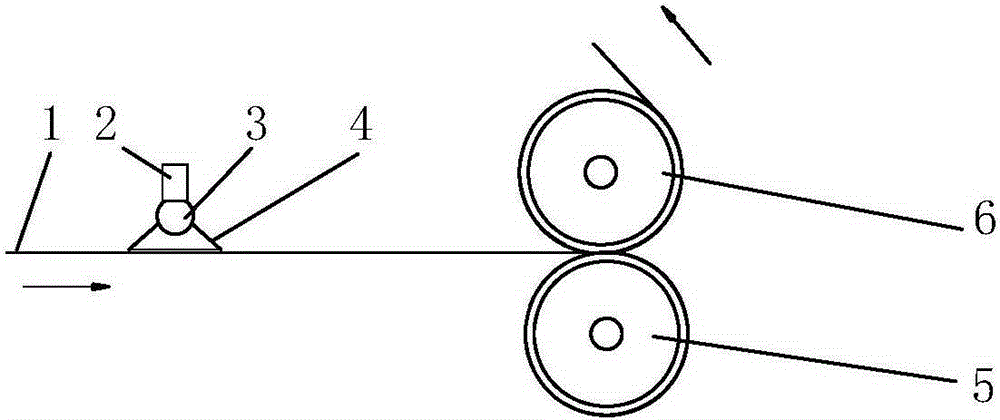

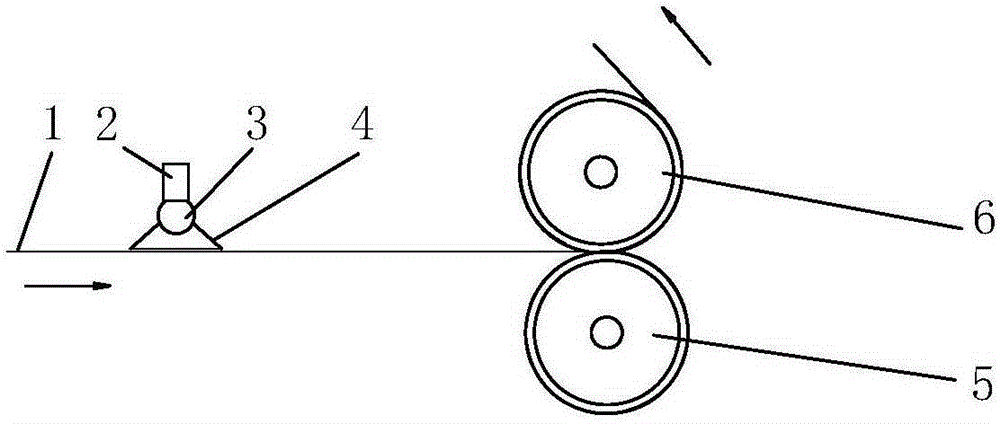

Water-saving and power-saving leather making equipment realizing segmented crease removal

The invention discloses water-saving and power-saving leather making equipment realizing segmented crease removal. The water-saving and power-saving leather making equipment comprises a heating roller, a pressurizing roller, a spray pipe and a fence ring, wherein two ends of the spray pipe are closed, the spray nozzle is located above cloth, an inlet is formed in the center and communicated with an ultrasonic water-atomizing generator, a plurality of spray holes are formed in the wall of the spray pipe and arranged as follows: space of the spray holes close to the center of the spray pipe is maximum, space of the spray holes close to two ends of the spray pipe is minimum, the space changes gradually, when the cloth passes through the part below the spray holes, the humidity of the two ends, contacted with atomized vapor, of the cloth is high, the humidity of center, contacted with the atomized vapor, of the cloth is low, and the humidity changes gradually; the fence ring comprises multiple circumferential strips with the same length and at least two axial strips and is mounted tightly to the inner wall of a roller ring of the heating roller, the adjacent circumferential strips have the same center space, the width of each circumferential strip is gradually reduced from the center to two ends of the roller ring, the temperature, transmitted from the fence ring to the roller ring, of high-temperature oil is reduced, the temperature of the position close to the two ends of the roller ring is the highest, and the temperature changes gradually. The water-saving and power-saving leather making equipment has the benefits of water saving, power saving, high-temperature, high-humidity and high-pressure setting and good accurate control effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

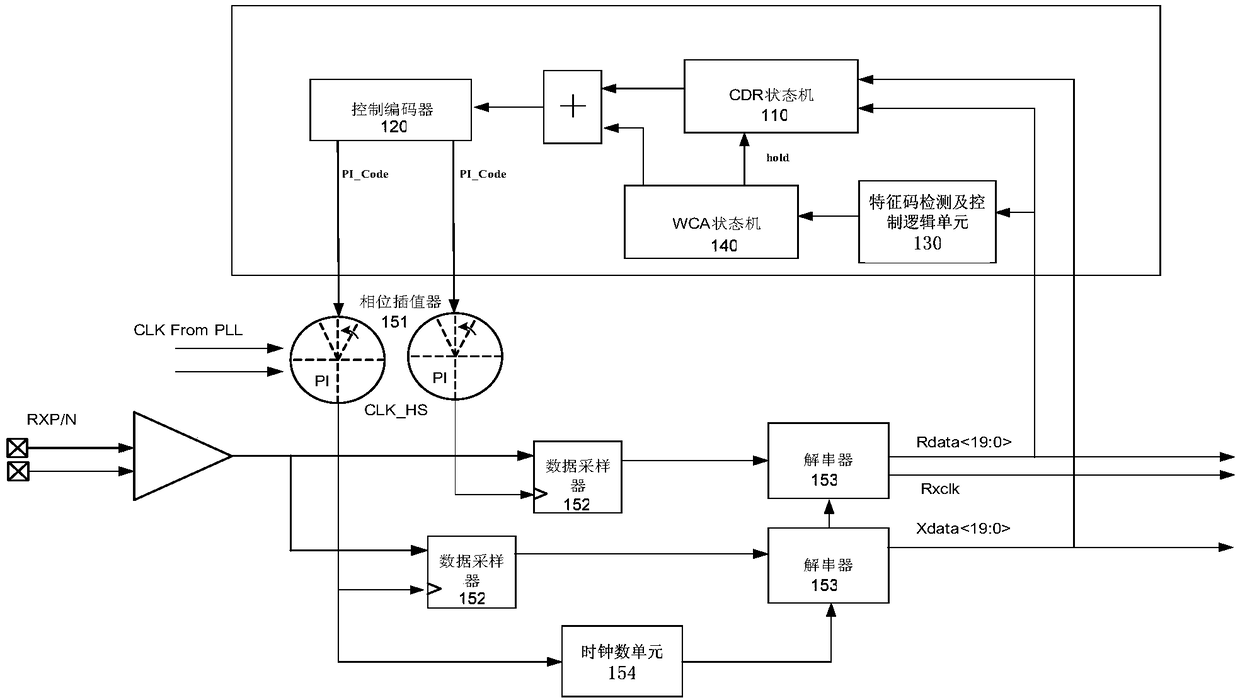

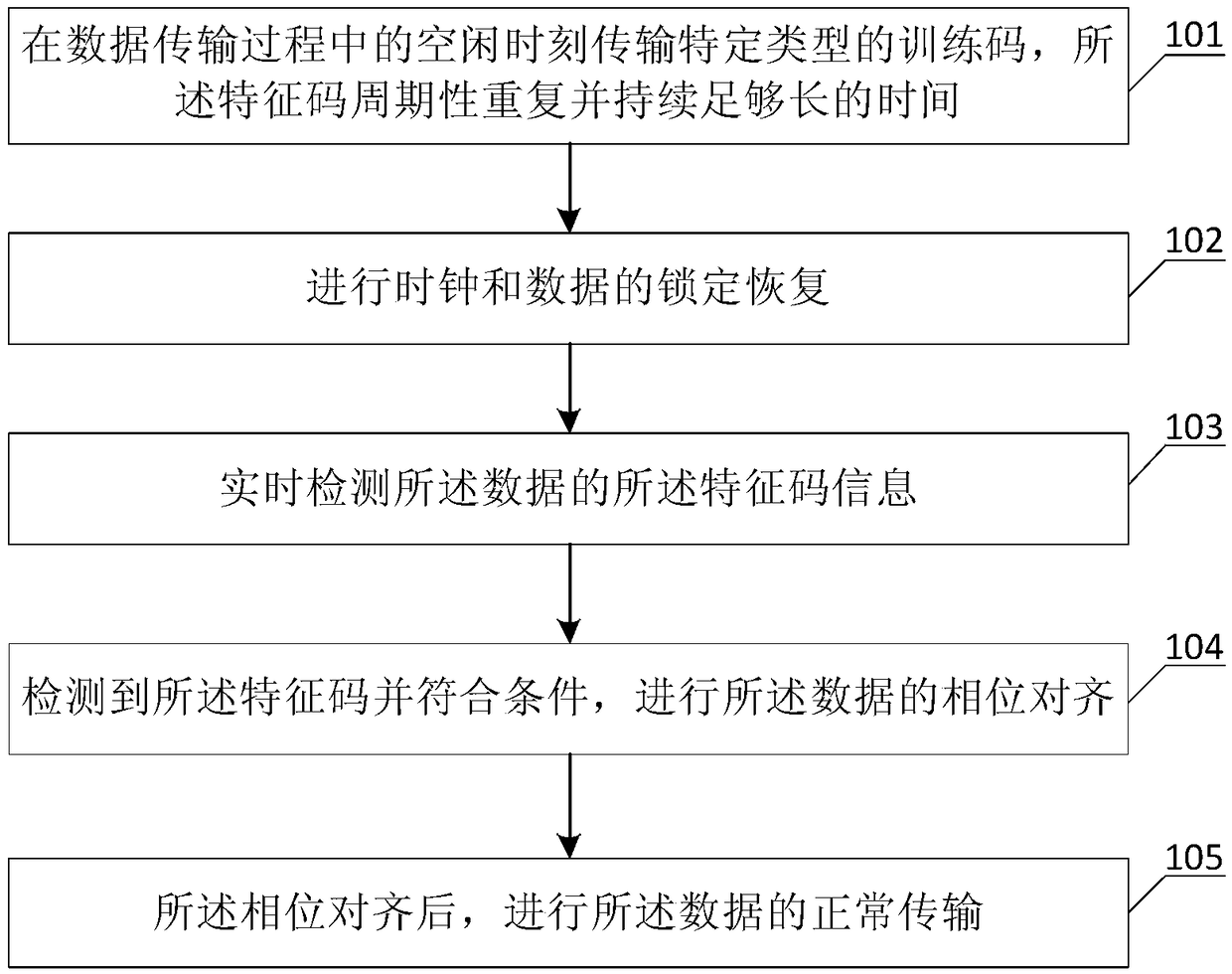

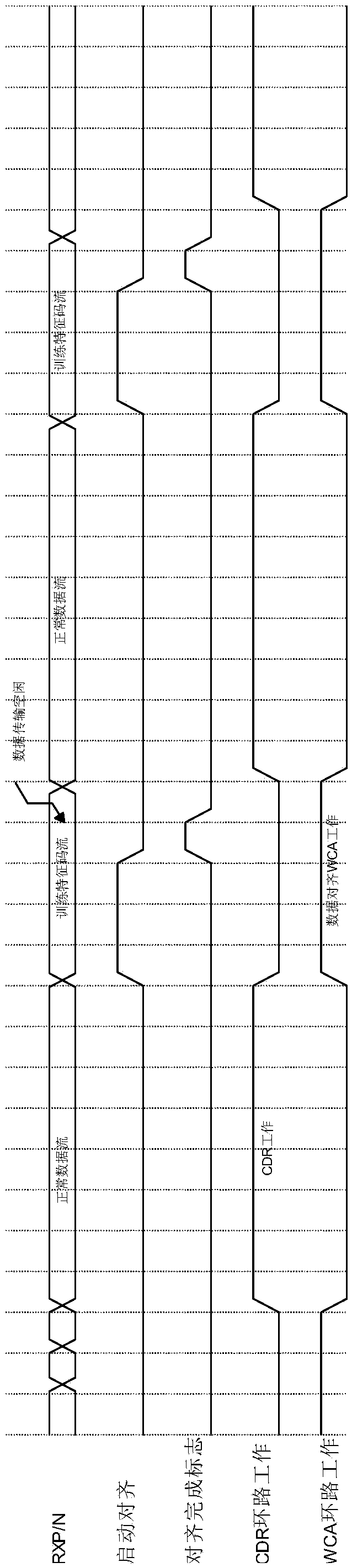

Channel phase alignment circuit and method

ActiveCN109450610AReduce serial-to-parallel conversion delayGood precision controlSynchronisation receiversSynchronisation signal speed/phase controlFeature codePhase alignment

The invention provides a channel phase alignment circuit, comprising: a data receiving end, a CDR state machine, a control encoder, a feature code detection and control logic unit, and a WCA state machine, wherein the data receiving end receives high-speed serial data, performs sampling and serial-to-parallel conversion on the serial data, and generates a parallel clock; the CDR state machine is used for performing recovery control of a clock and data, and obtaining a phase corresponding relationship between a high-speed sampling clock and the data; the control encoder is used for converting the phase corresponding relationship into a control code of a high-speed clock interpolator; the feature code detection and control logic unit is used for monitoring a training feature code pattern ina serial data stream; and the WCA state machine is used for calculating a phase and a word boundary of the data, and switching a CDR loop to a WCA loop for phase alignment after the training feature code is detected for multiple times and has the same phase information. The invention further provides a channel phase alignment method, which can be used for performing accurate data word boundary alignment.

Owner:成都华大九天科技有限公司

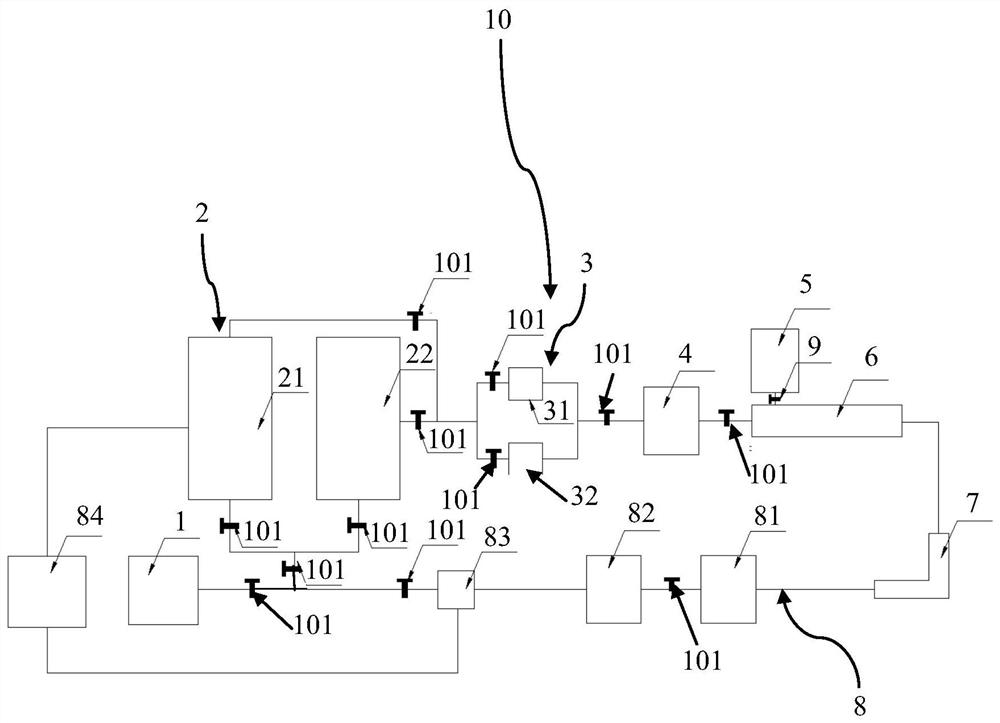

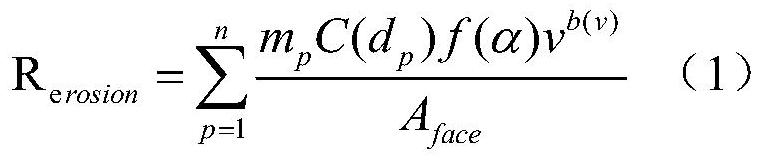

Experimental device

PendingCN112014255AThe experimental operation process is safe and reliableGuaranteed cycleMachine valve testingInvestigating abrasion/wear resistanceEngineeringGas holder

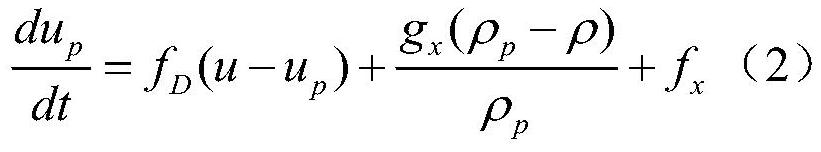

The invention provides an experimental device. The experimental device comprises a gas source, a high-pressure gas storage tank, a high-pressure pump, a fluid heater, a high-pressure solid storage tank, a mixing device and a throttle valve test piece, wherein the gas source is connected with the high-pressure gas storage tank, and the high-pressure pump is respectively connected with the high-pressure gas storage tank and the fluid heater; the high-pressure fixed storage tank and the fluid heater are respectively connected with the mixing device, and the mixing device is connected with the throttle valve test piece. The gas source is carbon dioxide gas. The experimental device provided by the invention can be used for simulating the erosive wear process of flammable and explosive gas-solidtwo-phase flow to the throttle valve indoors for the throttle valve commonly used in the current well testing process, researching the erosive wear rule of different parameters to the throttle valve,and is safe and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ironing and heating equipment for tanning

InactiveCN105072717AReasonable structureLow costHeater elementsTextiles and paperEngineeringDensity change

The invention discloses ironing and heating equipment for tanning, which comprises an electric heater, wherein the electric heater is composed of an electric heating wire, an insulating frame and a heat concentrating cover; the electric heater is installed on a machine frame and can be used for heating a roller ring; the electric heating wire is wound on the insulating frame, is wound densely at positions close to both ends of the roller ring, and is wound sparsely at a position close to the center of the roller ring, and the density changes gradually; two ends of the roller ring obtain more heat quantity and are higher in temperature, the center of the roller ring obtains fewer heat quantity and is lower in temperature, and the temperature changes gradually; a heating roller is an electric heating roller or an oil heating roller which heats evenly; the insulating frame is made from a ceramic plate, and the ceramic plate is provided with embossments for hooking the electric heating wire; and the center of the roller ring refers to a distance J, the electric heating wire is evenly wound within the distance J, and the corresponding temperature of the center of the roller ring is identical. The ironing and heating equipment for tanning has the beneficial effects of reasonable structure, low cost, heat energy, water and electricity conservation, sectional high temperature setting and good precise control effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

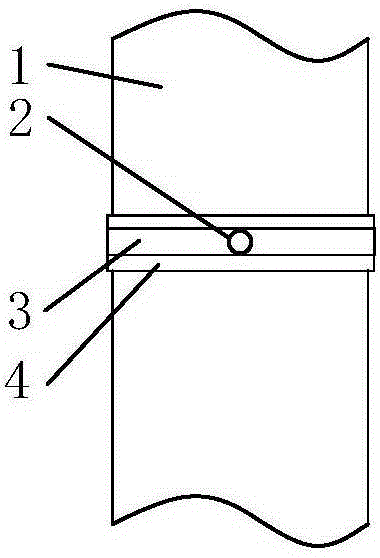

Water-saving and power-saving wrinkle removal equipment for synthetic leather processing

InactiveCN105002743AReasonable structureLow costTextile treatment by spraying/projectingTextile shapingWrinkle skinWater saving

The invention discloses water-saving and power-saving wrinkle removal equipment for synthetic leather processing. The equipment comprises a heating roll and a pressurizing roll which are mutually matched, wherein the heating roll comprises an inner cylinder provided with a first insulating material on the outer surface and an electric heating wire winding the first insulating material on the inner cylinder, the electric heating wire close to two ends of the inner cylinder is wound densely, the electric heating wire close to the center of the inner cylinder is wound sparsely, the gradual density transition of the electric heating wire is realized, the inner cylinder is nested in the a roll ring, and space between the electric heating wire and the inner surface of the roll ring is filled with a second insulating material; when the electric heating wire heats, temperatures of two ends of the roll ring are the highest, and the central temperature of the roll ring is the lowest; a spray pipe is located above cloth and is communicated with an ultrasonic water atomization generator; a plurality of spraying holes are formed in the wall of the spray pipe, the center interval between every two of the spraying holes is identical, the area of each of spraying holes close to two ends of the spray pipe is larger than that of each of spraying holes close the center of the spray pipe, and the areas of the spraying holes gradually change from two ends to the center. The equipment has the benefits as follows: the equipment is power-saving, water-saving, can realize setting at high temperature and under conditions of high humidity and high pressure and has a good accurate control effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

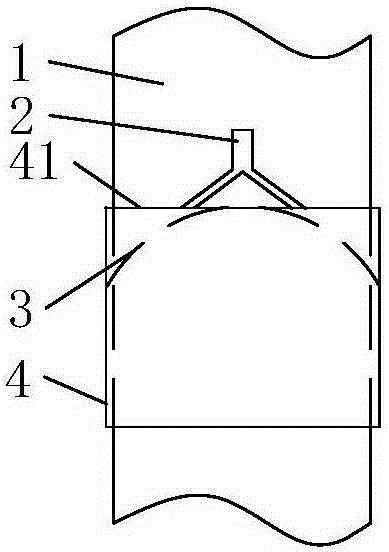

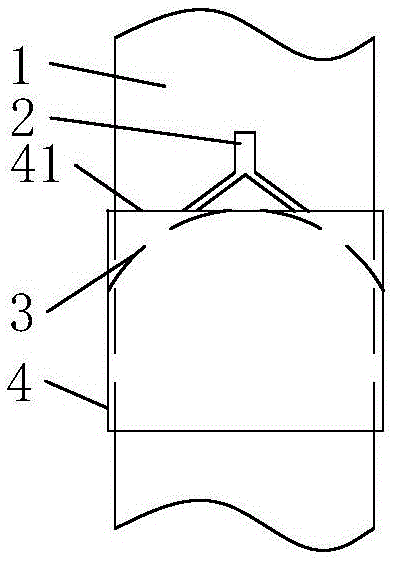

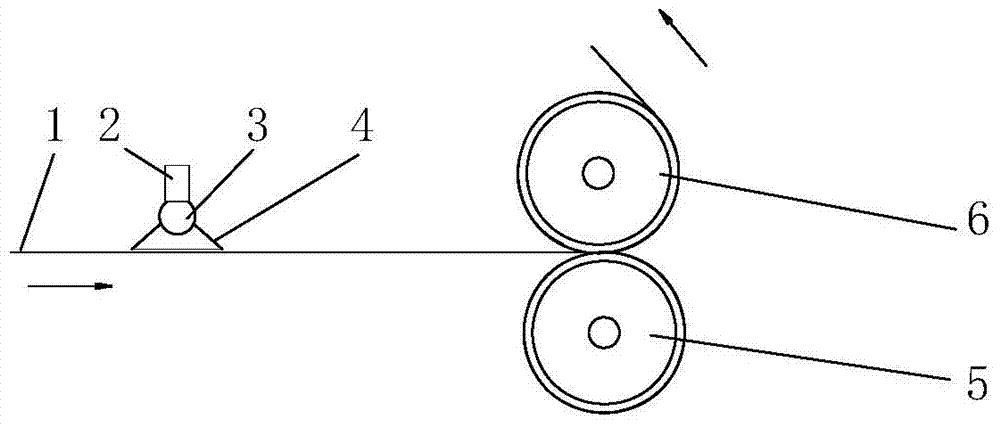

Segmented ironing tanning device

InactiveCN105064054AReasonable structureLow costTextile treatment machine arrangementsTextile treatment by spraying/projectingElectricityEngineering

The invention discloses a segmented ironing tanning device. The segmented ironing tanning device comprises a heating roller and a pressurizing roller which are used for heating and pressurizing cloth, and further comprises a spraying pipe and an electric heater. The spraying pipe is located above the cloth. An inlet is formed in the center of the spraying pipe and communicated with an ultrasonic water atomization generator. Two symmetrically-formed spraying holes in a V shape are formed in the pipe wall of the spraying pipe. The pointed part of the V shape is close to the center of the spraying pipe. When the cloth passes through the portion below the spraying holes, the humidity of atomization steam in contact with the two ends of the cloth is high, and humidity is gradually changed. The electric heater is composed of an electric heating wire, an insulation frame and a heat gathering cover. The electric heater is installed on a machine frame and can heat a roller ring. The electric heating wire is wound around the insulation frame, the wound portions, close to the two ends of the roller ring, of the electric heating wire are thick, the wound portions, close to the center of the roller ring, of the electric heating wire are thin, and the thin-thick degree is gradually changed. The heat obtained by the two ends of the roller ring is much, and the temperature of the two ends of the roller ring is high; the heat obtained by the center of the roller ring is little, and the temperature of the center of the roller ring is low; the temperature is gradually changed. The segmented ironing tanning device has the advantages that heat energy, water and electricity are saved, high-temperature, high-moisture and high-pressure shaping is carried out, accurate control is achieved, and the effect is good.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

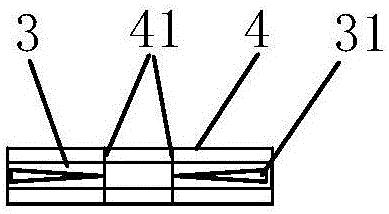

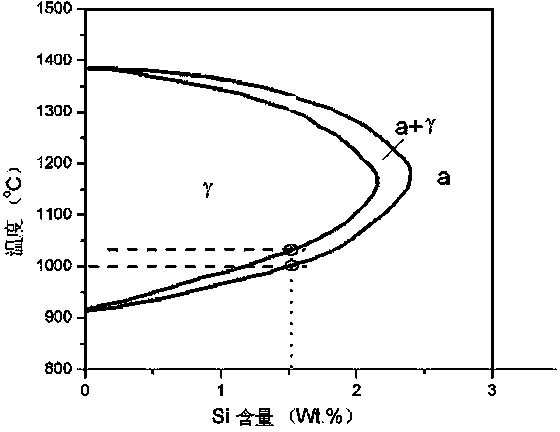

Non-oriented silicon steel hot rolled plate rolling method controlled through silicon equivalent

InactiveCN102921725AGood precision controlControl precisionMetal rolling arrangementsProfile control deviceMolten steelLiquid steel

Provided is a non-oriented silicon steel hot rolled plate rolling method controlled through silicon equivalent. The steps of the method are that blanks are formed through smelting and continuous casting; the silicon equivalent is determined according to liquid steel end composition; phase-transition temperature is determined; the casting blank heating temperature range is determined; rolling is carried out; conventional reeling up is carried out for preparation. According to the silicon equivalent computational formula of the non-oriented silicon steel hot rolled plate rolling method controlled through the silicon equivalent, the rolling phase-transition temperature range can be accurately grasped, accurate rolling technology can be achieved, so that the temperature during the rolling process effectively avoids the phase-transition temperature, and accordingly the accuracy of the plate shape is improved to more than 98% from the original accuracy of 95%, the accuracy of the width can be well controlled, the rejection rate of rolling is lowered to less than 0.75% from the original rate of 3.1%, and the rolling technology parameters are easy and quick to obtain.

Owner:武汉钢铁有限公司

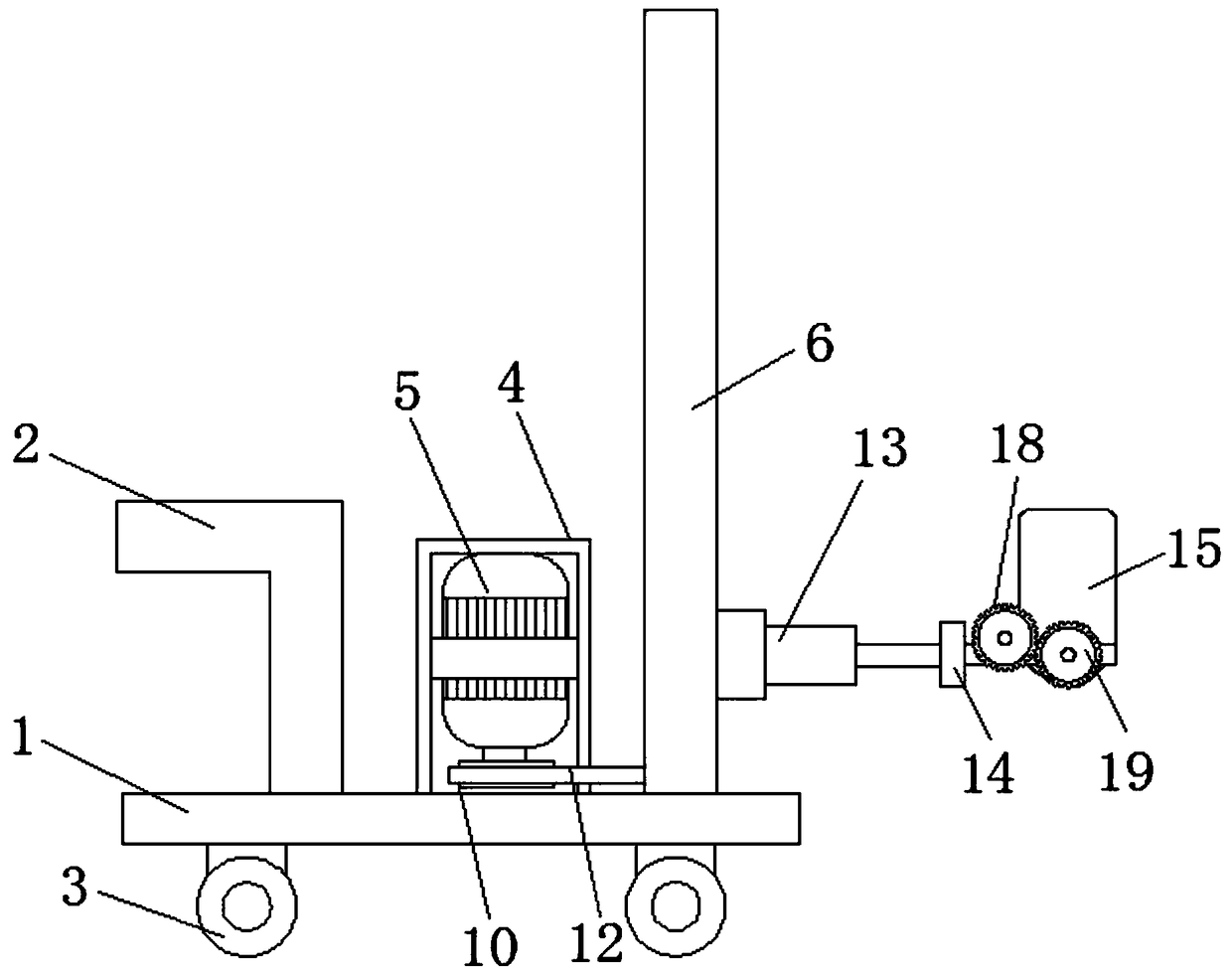

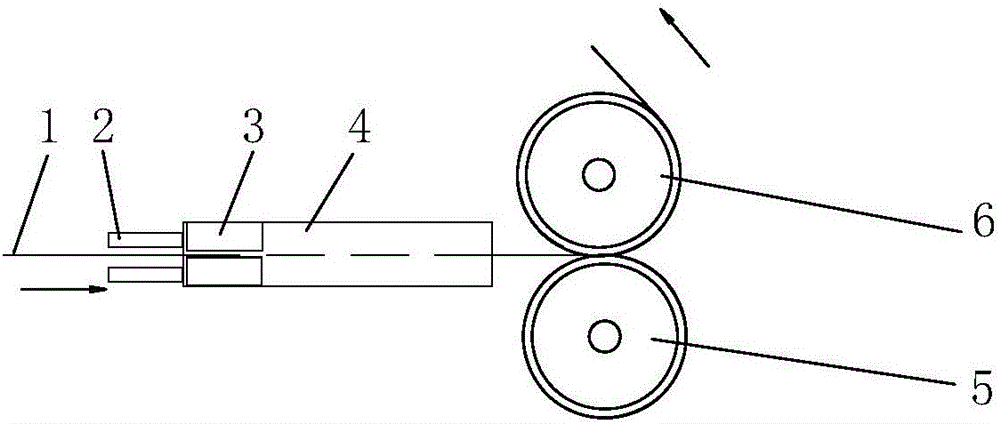

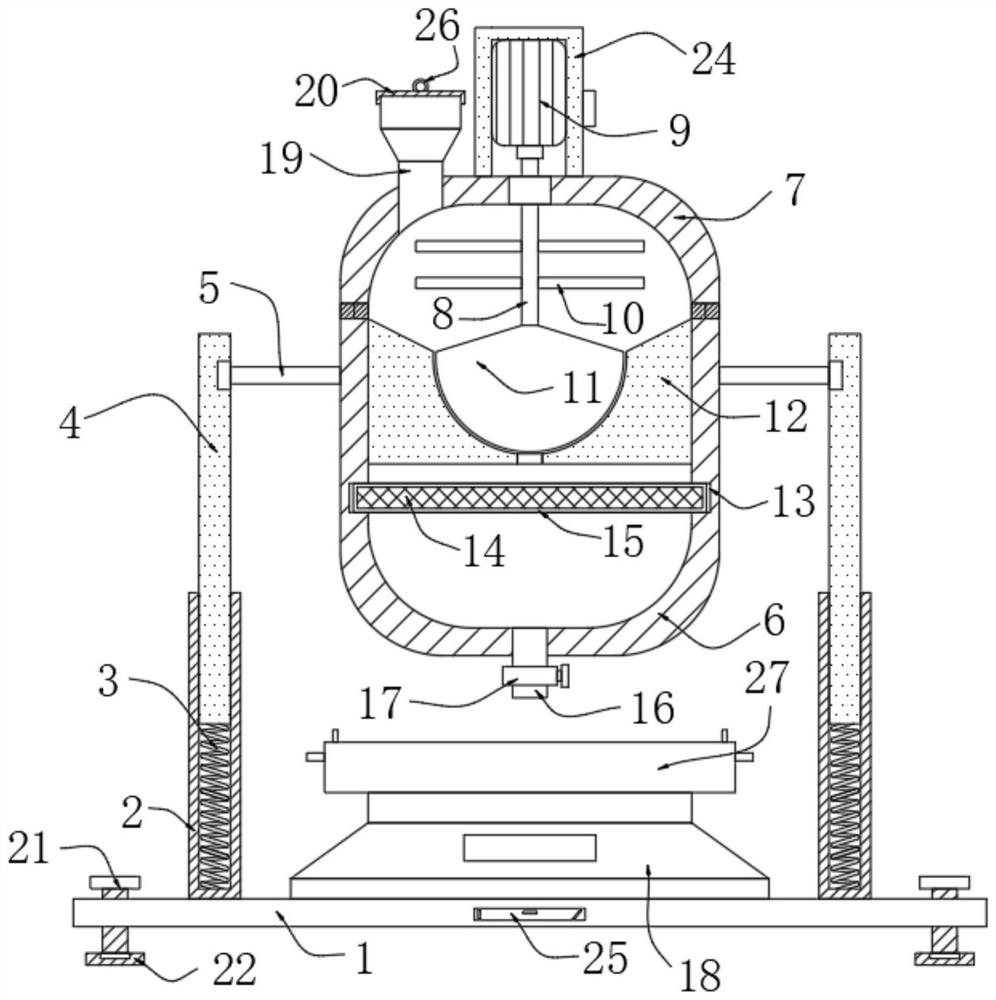

Quantitative feeding device for building decoration material

The invention discloses a quantitative feeding device for a building decoration material. The device comprises a baseplate, a connection rack, a first motor, a lifting rack, air cylinders and a material barrel. Idler wheels are fixedly arranged at the four corners of the bottom face of the baseplate respectively, the lifting rack is fixedly arranged at the other side of the upper face of the baseplate, and a lead screw is rotatably arranged in the lifting rack through a bearing base; a slide block is in threaded connection with the lead screw, slide rods are fixedly arranged on the portions, of the two sides of the lead screw, of the inner side of the lifting rack respectively and slidingly connected with the slide block, and the two air cylinders are fixedly arranged at the side, away from the first motor, of the slide block; retractable shafts of the air cylinders are fixed to one side of a fixing plate, a horizontal plate is fixedly arranged at the other side of the fixing plate, and the material barrel is rotatably connected with the horizontal plate. Through rotation of the lead screw in the lifting rack, the slide block is driven to ascend and descend, the material barrel atthe other side is driven to ascend and descend accordingly, the feeding process is completed, blocking of the material in the material barrel can be effectively reduced, and the device is efficient and practical.

Owner:安徽稀饭智能家居有限公司

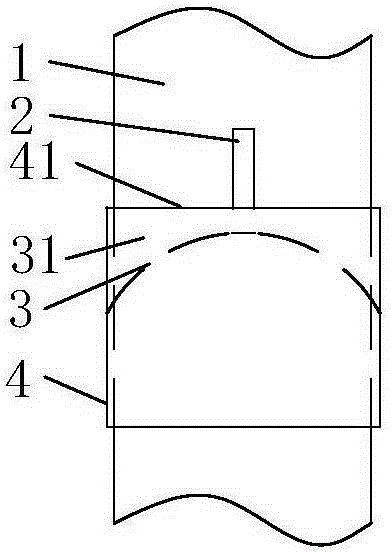

Energy-saving ironing equipment based on synthetic leather processing

InactiveCN105064059AReasonable structureLow costTextile treatment by spraying/projectingTextile shapingHigh humidityEngineering

The invention discloses energy-saving ironing equipment based on synthetic leather processing. The energy-saving ironing equipment comprises a heating roller, a compressing roller, a humidifying box, a steam nozzle and a steam partition plate. The steam nozzle is communicated with an ultrasonic water atomization generator. The steam partition plate is mounted in the humidifying box. Oblique planes relative to the mounting face of the steam nozzle are arranged at the two ends of the steam partition plate. Humidifying spaces defined by the steam partition plate, the humidifying box and cloth can meet the requirement that when the cloth penetrates through the humidifying spaces, the time for the two ends of the cloth to make contact with atomization steam is long, and the time for the position close to the center of the cloth to make contact with atomization steam is short. The heating roller comprises a heat gathering barrel. The heat gathering barrel is composed of a hollow body and a plurality of heat gathering pieces arranged on the inner wall of the hollow body. The outer surface of the hollow body is tightly attached to the inner wall of a roller ring. The heat gathering pieces are of a symmetrical double-triangle structure, and the tips of the double triangles are close to the center of the hollow body. The heat gathering barrel can absorb heat from high-temperature oil, the temperature of the positions close to the two ends of the roller ring is high, and the temperature is changed gradually. The energy-saving ironing equipment has the advantages that heat energy and water are saved, high-temperature, high-humidity and high-pressure shaping is realized, and the precise control effect is good.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Heating roller of ironing equipment based on synthetic leather processing

The invention discloses a heating roller of ironing equipment based on synthetic leather processing. The heating roller comprises a roller ring, two roller end surfaces and a roller shaft, wherein the roller shaft is mounted on a rack through a bearing, and high-temperature oil in the heating roller is communicated with a heating oil tank through an oil pump; a round heat-collection barrel comprises a hollow body and a plurality of heat-collection pieces arranged on the inner wall of the hollow body, the outer surface of the hollow body is tightly attached to the inner wall of the roller ring, each heat-collection piece adopts a structure of symmetrical double triangles, apexes of the double triangles are close to the center of the hollow body, the round heat-collection barrel can absorb heat from the high-temperature oil and transfer the heat to the roller ring, the temperature of positions close to two ends of the roller ring is high, the temperature of a position close to the center of the roller ring is low, and the temperature changes gradually. According to the fact that the apexes of the double triangles of each heat-collection piece are close to the center of the hollow body, the center refers to a distance J, and the temperature of the corresponding roller ring center is equal in the distance J. The heating roller of the ironing equipment based on synthetic leather processing has the benefits of reasonable structure, low cost, electricity saving, water saving, high-temperature, high-humidity and high-pressure setting and good accuracy control effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

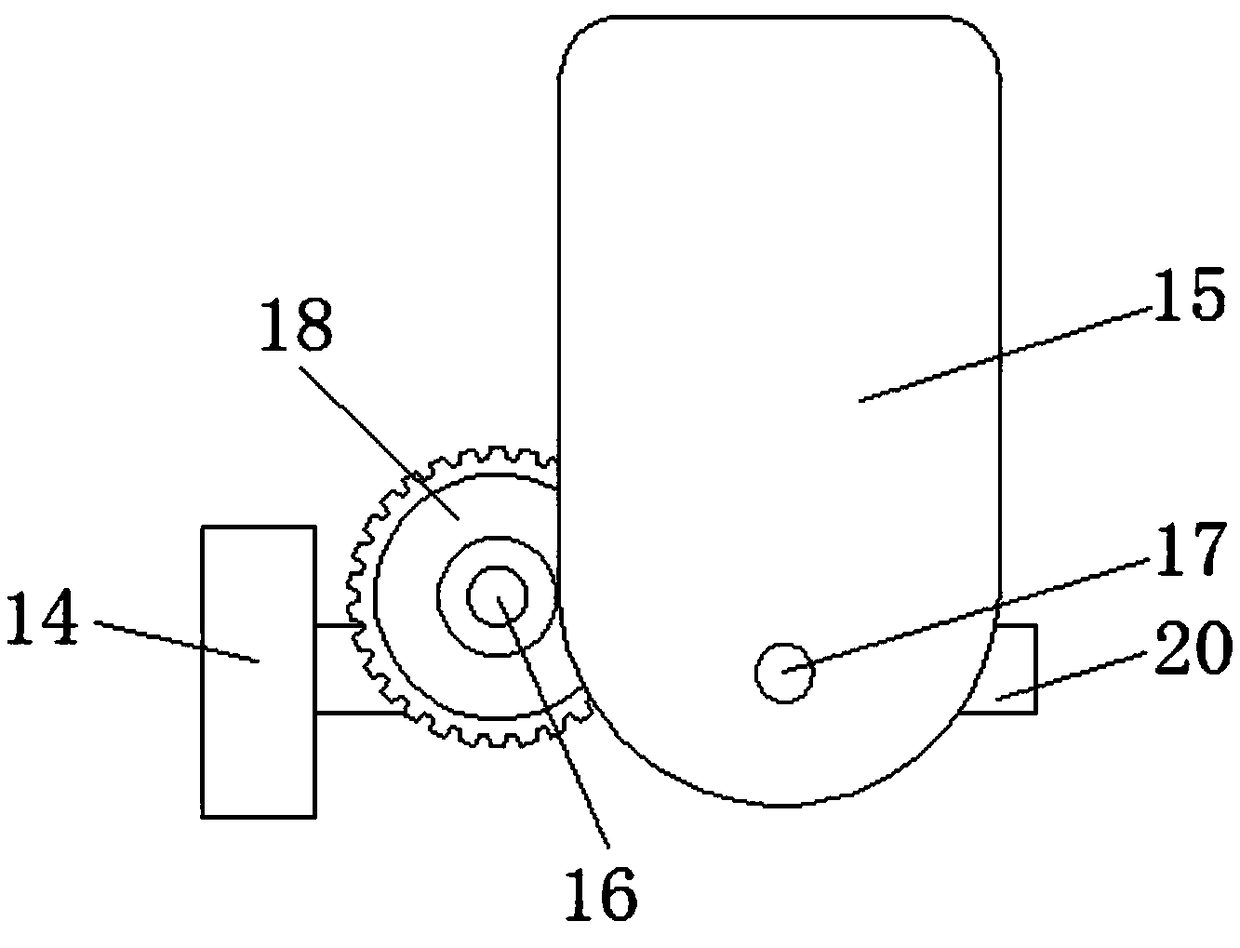

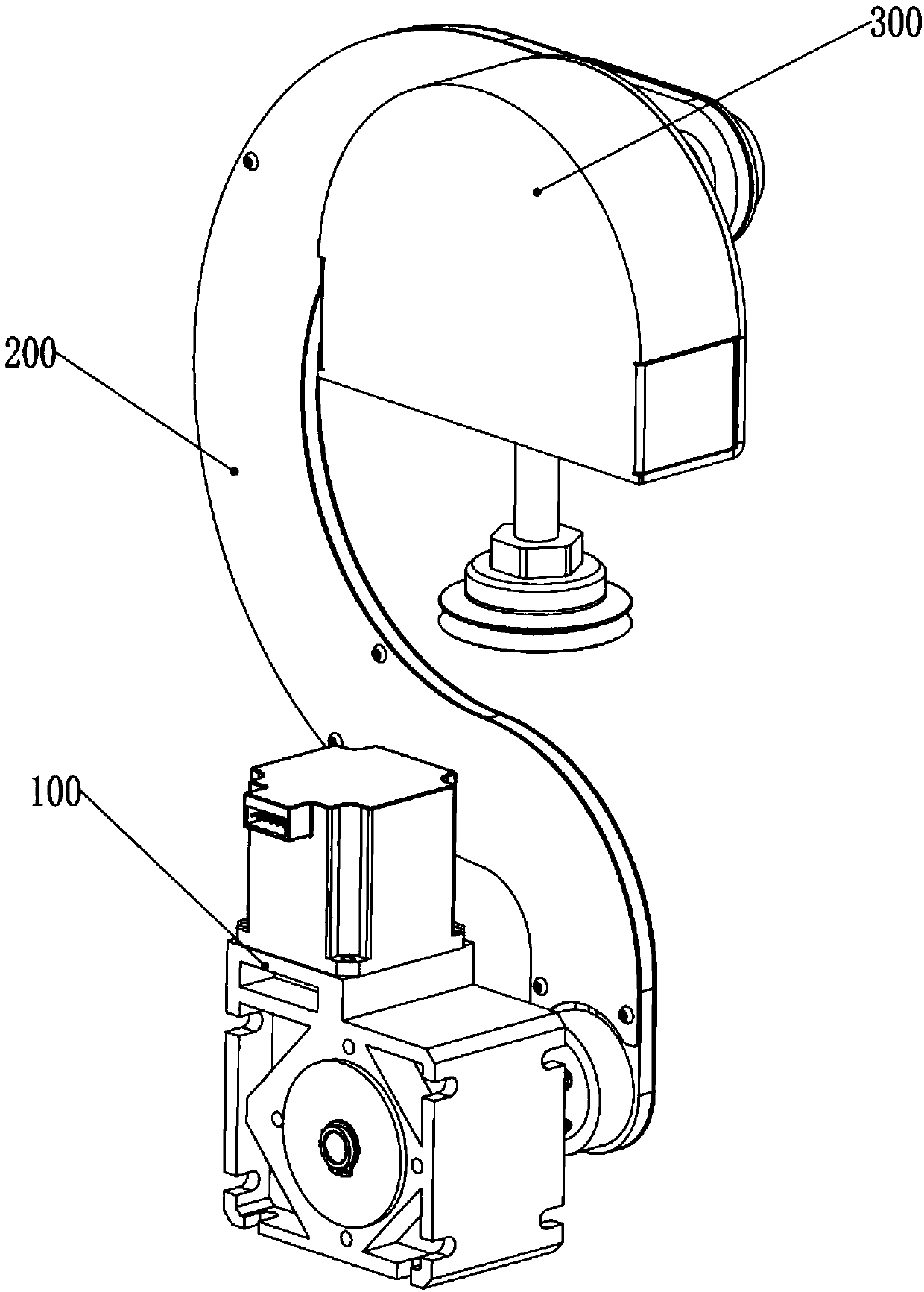

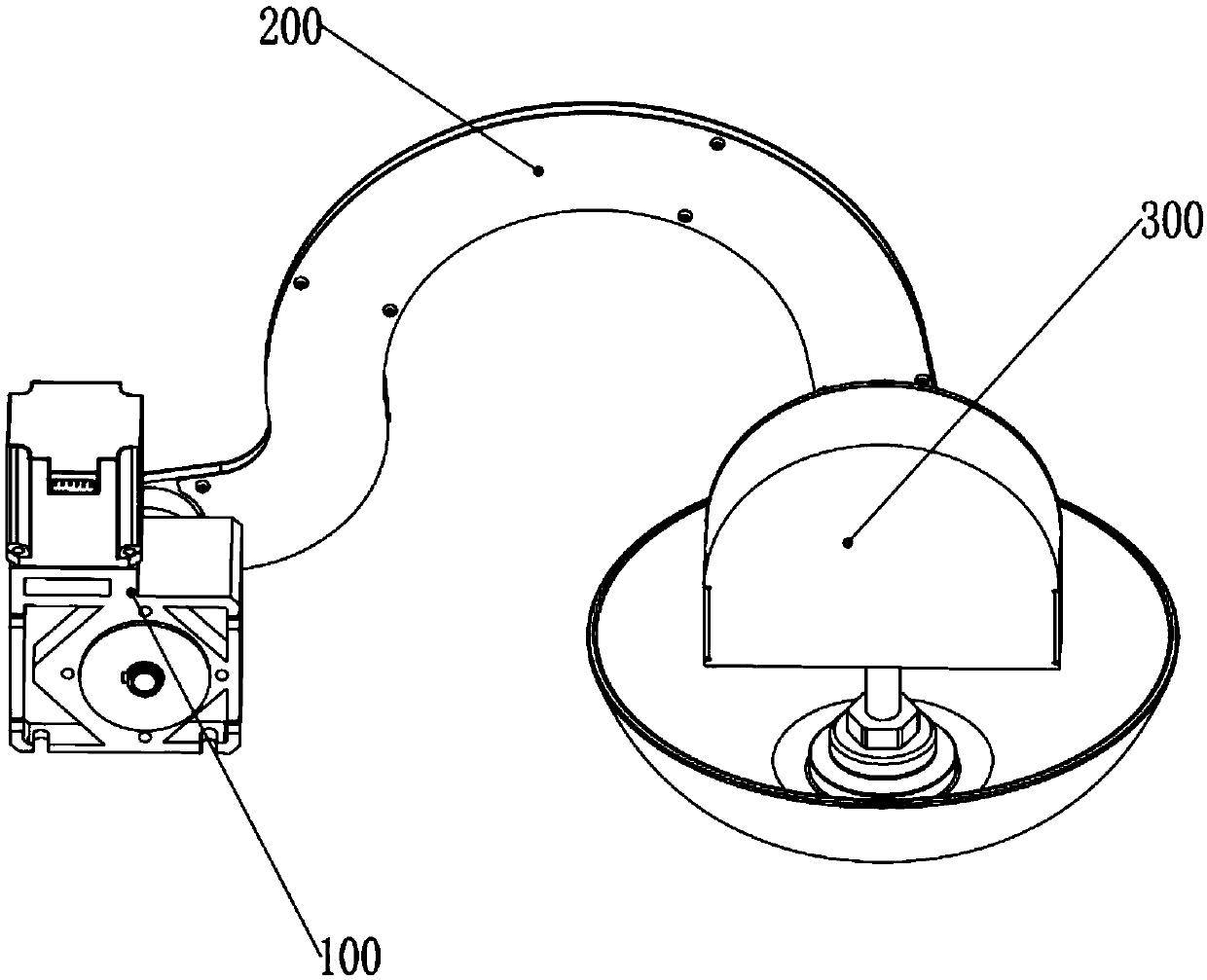

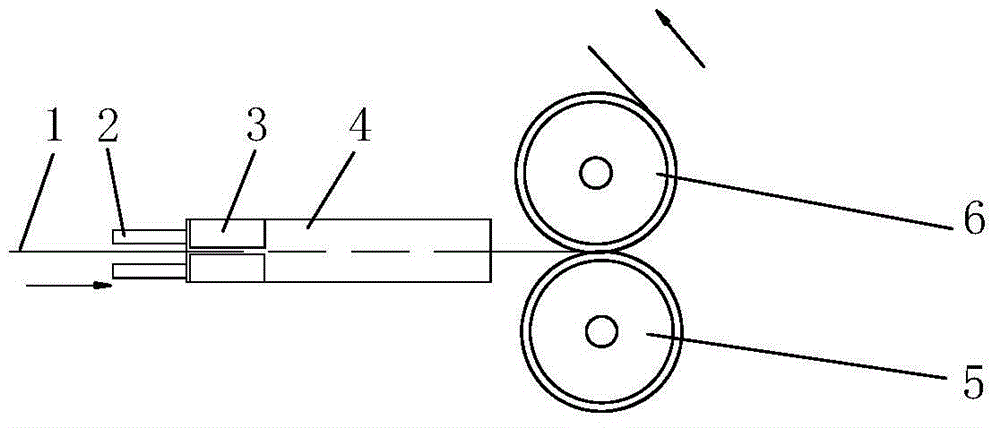

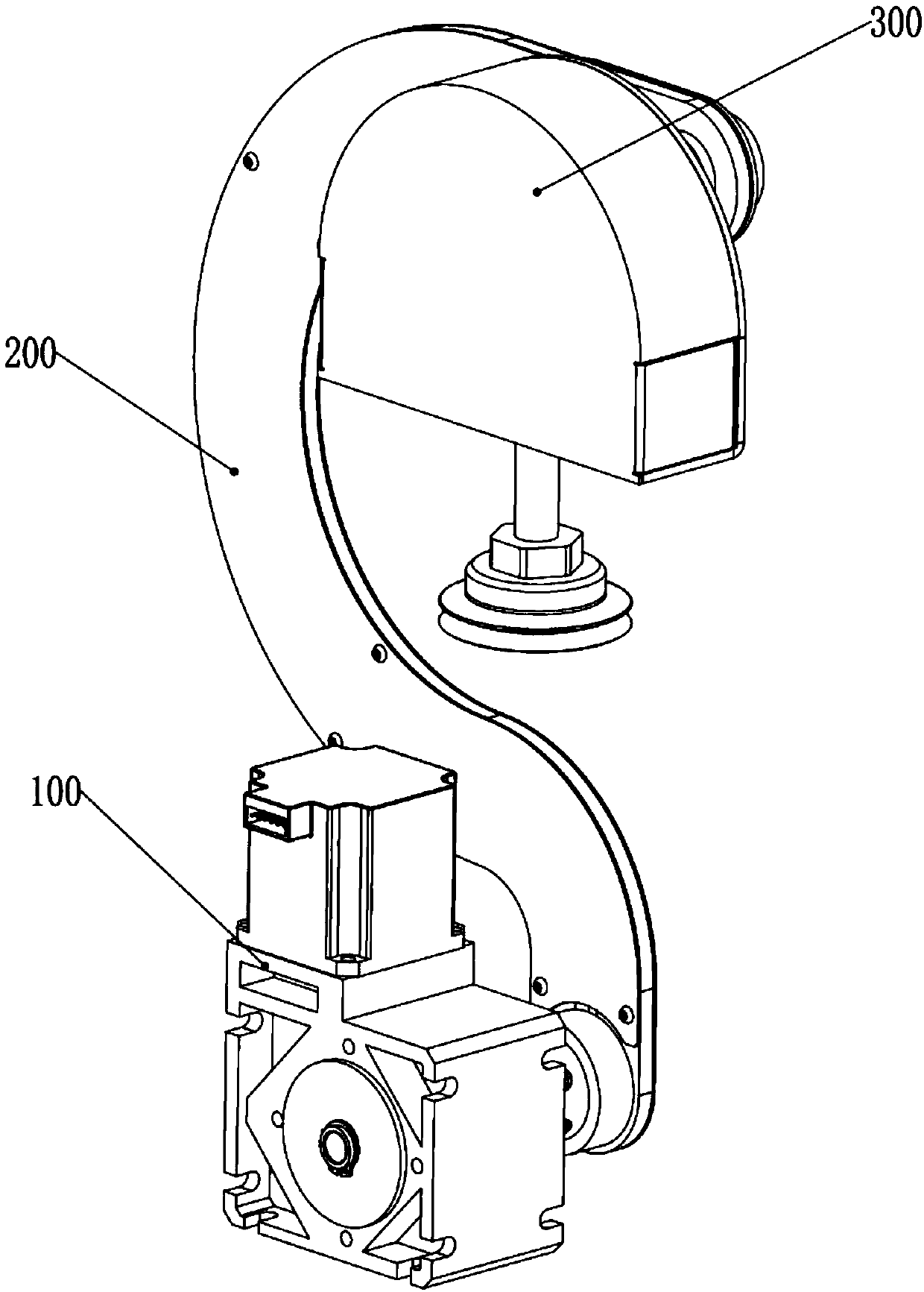

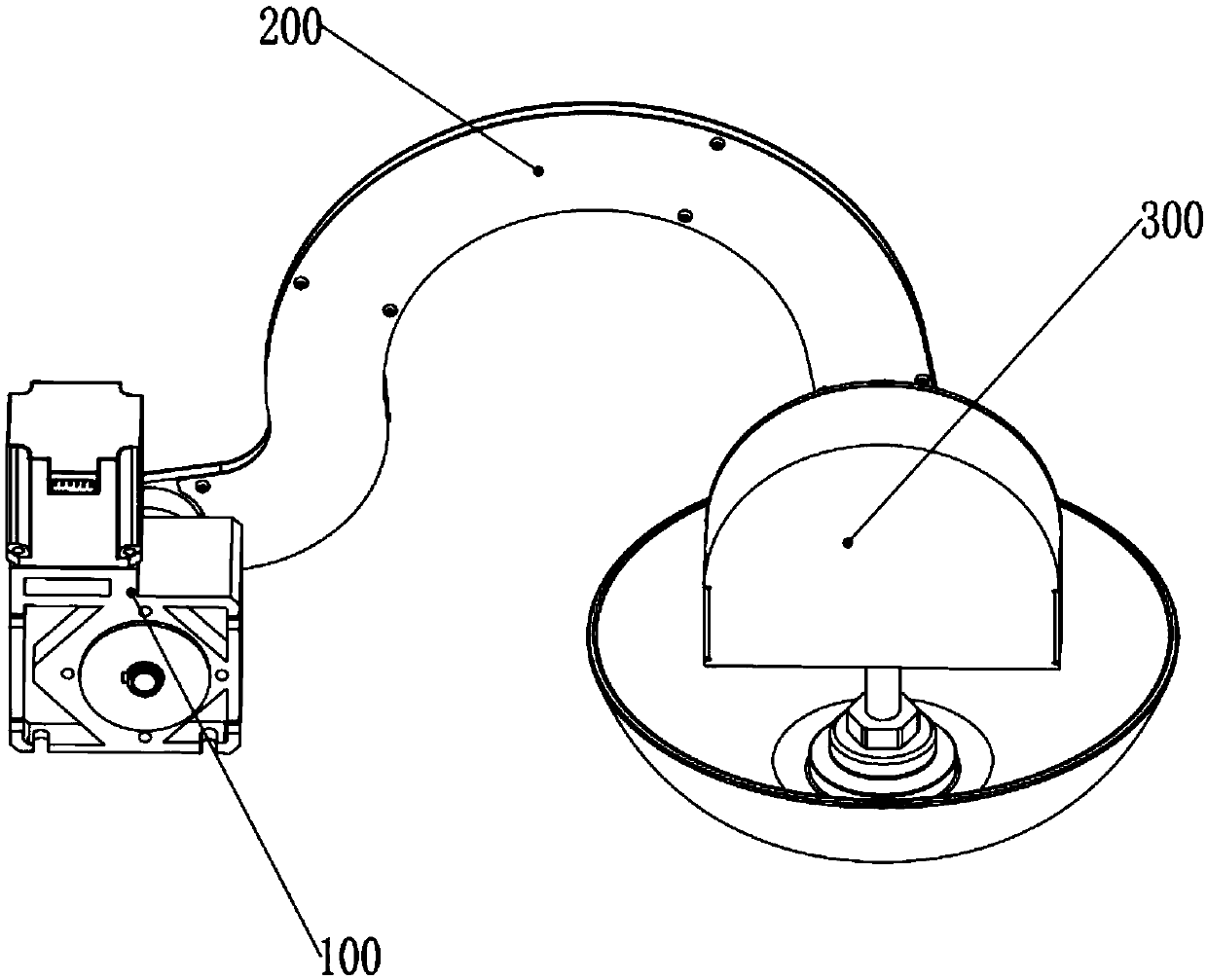

Sucker bowl taking device

ActiveCN111319970AGood suction freedomGood precision controlConveyorsApparatus for dispensing fluids/granular materialsElectric machineryEngineering

The invention relates to the technical field of kitchen equipment, in particular to a sucker cup bowl taking device. The sucker cup bowl taking device comprises a control box assembly, a swing arm assembly and a motor assembly, wherein the swing arm assembly comprises a swing arm body, and the swing arm body is provided with a swing bearing; the control box assembly comprises a control box shell,a swing rotating shaft, a vacuum pump and a suction cup; the swinging rotating shaft penetrates through the swinging bearing; and the vacuum pump communicates with a sucker through an air pipe. According to the sucker bowl taking device, the arranged swing arm assembly has a larger suction range, the horizontal rotation radius is small, the rotation gravity center is concentrated and more stable,and the control box assembly can swing within a certain range to cater to inclined bowls, so that the sucker bowl taking device has the good suction freedom degree and accurate controllability, and can adapt to more different types of bowls with inconsistent placement conditions, the bowl sucking operation is more flexible and rapid, and bowl sucking and moving are more accurate and stable.

Owner:北京快端科技有限公司

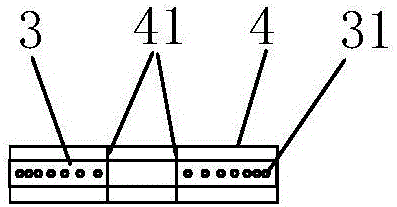

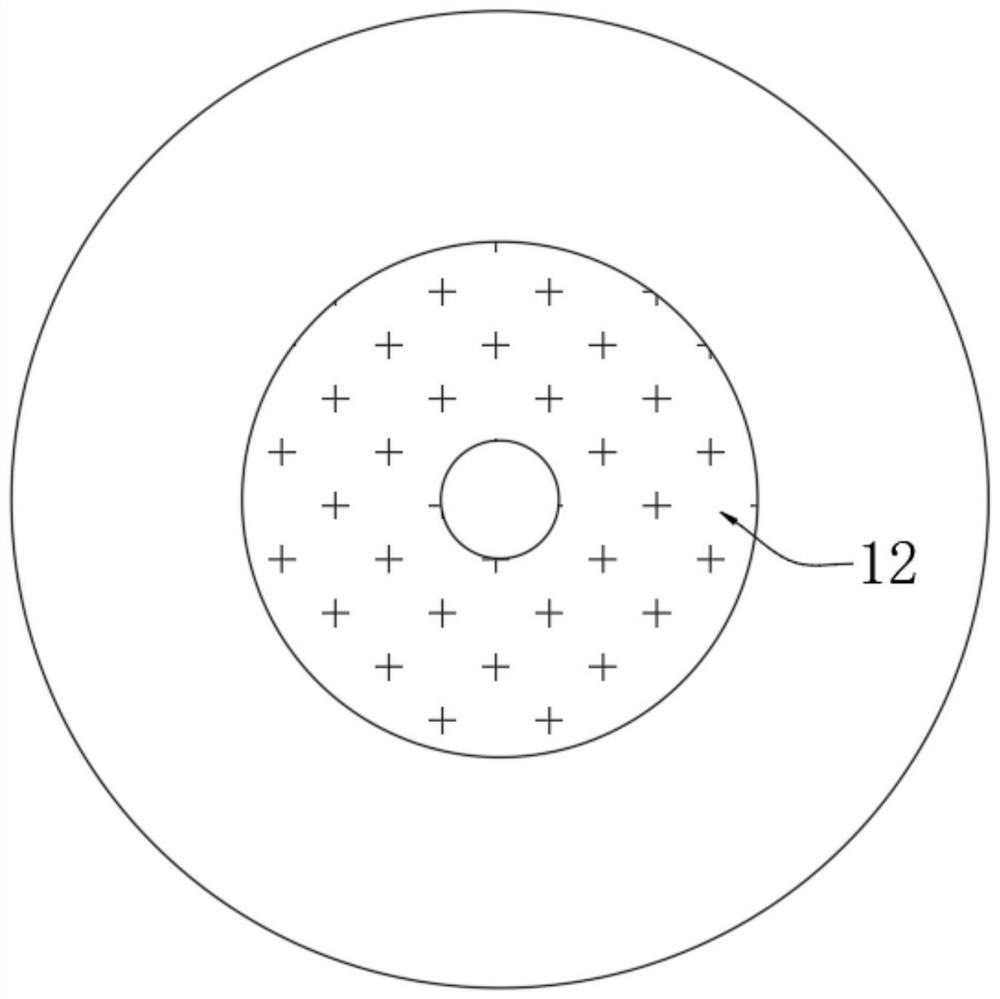

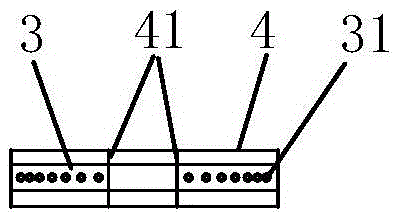

Heating roller of tanning wrinkle removal equipment

The invention discloses a heating roller of tanning wrinkle removal equipment. The heating roller is composed of a roller ring, two roller end faces and a roller shaft. The roller shaft is mounted on a rack through bearings, and high-temperature oil in the heating roller is communicated with a heating oil tank through an oil pump. The heating roller further comprises a fence ring. The fence ring is composed of a plurality of peripheral strips which are the same in length and two or more axial strips and tightly attached to the inner wall of the roller ring, the center intervals of adjacent peripheral strips are the same, and the widths of the peripheral strips are gradually decreased from the center of the roller ring to the two ends of the roller ring; the high-temperature oil is conducted to the roller ring from the fence ring, the temperature is lowered, the temperatures of the positions close to the two ends of the roller ring are the highest, the temperature of the position close to the center of the roller ring is the lowest, and the temperatures gradually change. The roller ring center refers to a distance J, in the distance J, the widths of the peripheral strips are the same, and the temperatures, corresponding to the peripheral strips, of the center of the roller ring are the same. The heating roller has the advantages that the structure is reasonable, the cost is low, heat energy and water are saved, high-temperature high-pressure shaping is achieved,a dn the accurate control effect is good.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Energy-saving tanning device with segmented wrinkle removal

InactiveCN105177890AReasonable structureLow costTextile treatment by spraying/projectingTextile shapingHigh humidityPulp and paper industry

The present invention discloses an energy-saving tanning device with segmented wrinkle removal. The device comprises a heating roller, an impression roller, a spray pipe, and a fence ring, wherein two end heads of the spray pipe are sealed the spray pipe is disposed above cloth, an inlet is arranged in the center of the spray pipe and is communicated with an ultrasonic wave water atomization generator, a plurality of spray holes are formed in a pipe wall of the spray pipe, center-to-center distance of the spray holes is the same, areas of the spray holes close to two ends of the spray pipe is larger than that of the spray holes adjacent to the center of the spray pipe and gradually change, and when the cloth passes below the spray holes, and humidity of the two ends of the cloth contacting atomizd steam is high; the fencing ring is composed of a plurality of circumferential strips of the same length and at least two axial strips, the fencing ring is installed close to an inner wall of a roller ring of the heating roller, center-to-center distance between adjacent circumferential strips is the same, the width of the circumferential strips reduces gradually from the center of the roller ring to two ends of the roller ring, and the temperature of a high temperature oil lowers after the oil is conducted to the roller ring, reaches the highest at positions close to the two ends of the roller ring, and changes gradually. The benefical effects of the tanning device are energy conservation, high temperature, high humidity and high pressure setting, and excellent precision control effects.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

Energy-saving leather making equipment capable of realizing segmented ironing

InactiveCN105155180AReasonable structureLow costTextile treatment containersTextile shapingElectricityHigh humidity

The invention discloses energy-saving leather making equipment capable of realizing segmented ironing. The equipment comprises a heating roller, a pressure applying roller, a humidification box, steam nozzles communicated with an ultrasonic water atomization generator, a steam isolating plate and an electric heater, wherein the steam isolating plate is arc-shaped and mounted in the humidification box, a humidification space is defined by the steam isolating plate, the humidification box and fabric, distances between two ends of the steam isolating plate and the steam nozzle mounting surface of the humidification box are long, and the distance between the center of the steam isolating plate and the steam nozzle mounting surface of the humidification box is short; the electric heater comprises an electric heating wire, an insulating frame and a heat collecting cover, is mounted on a rack and can heat a roller ring, the electric heating wire winds around the insulating frame, parts, close to two ends of the roller ring, of the electric heating wire wind densely, the part, close to the center of the roller ring, of the electric heating wire winds sparsely, the density changes gradually, the two ends of the roller ring obtain more heat and have higher temperatures, the center of the roller ring obtains less heat and has the lower temperature, and the temperatures change gradually. The equipment has the benefits as follows: the equipment is reasonable in structure, low in cost, good in accurate control effect and capable of saving heat energy, water and electricity and realizing high-temperature, high-humidity and high-pressure setting.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Synthetic leather processing and wrinkle-removing equipment capable of saving water and electricity

The invention discloses synthetic leather processing and wrinkle-removing equipment capable of saving water and electricity. The equipment comprises a heating roller and a pressing roller, which cooperates with the heating roller, and also comprises a spray pipe. Two ends of the spray pipe are sealed, the spray pipe is arranged above cloth, the center of the spray pipe is provided with an inlet, the inlet is communicated with an ultrasonic water atomization generator, two V-shaped spray holes are symmetrically arranged in the wall of the spray pipe, the sharp part of each V shape is close to the center of the spray pipe; when cloth goes through the space under the spray holes, the humidity of atomized gas that contacts two ends of the cloth is high, and the humidity changes gradually. The equipment comprises a heat trapping barrel, which is composed of a hollow body and a plurality of heat trapping sheets arranged on the internal wall of the hollow body. The external surface of the hollow body is tightly attached on the inner wall of a roller ring. Each heat trapping sheet is in a symmetric double-triangular structure; and the sharp parts of double triangles are close to the center of the hollow body, so that the heat trapping barrel can absorb thermal energy from high temperature oil and transmit the thermal energy to the roller ring. The temperature of position that is closer to two ends of the roller ring is higher, and the temperature changes gradually. The provided equipment has the advantages that the electricity and water are saved, the moulding is carried out under conditions of high temperature, high humidity and high pressure, and the effect can be precisely controlled.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

An energy-saving tanning equipment for segmented wrinkle removal

InactiveCN105177890BReasonable structureLow costTextile treatment by spraying/projectingTextile shapingHigh humidityEngineering

The present invention discloses an energy-saving tanning device with segmented wrinkle removal. The device comprises a heating roller, an impression roller, a spray pipe, and a fence ring, wherein two end heads of the spray pipe are sealed the spray pipe is disposed above cloth, an inlet is arranged in the center of the spray pipe and is communicated with an ultrasonic wave water atomization generator, a plurality of spray holes are formed in a pipe wall of the spray pipe, center-to-center distance of the spray holes is the same, areas of the spray holes close to two ends of the spray pipe is larger than that of the spray holes adjacent to the center of the spray pipe and gradually change, and when the cloth passes below the spray holes, and humidity of the two ends of the cloth contacting atomizd steam is high; the fencing ring is composed of a plurality of circumferential strips of the same length and at least two axial strips, the fencing ring is installed close to an inner wall of a roller ring of the heating roller, center-to-center distance between adjacent circumferential strips is the same, the width of the circumferential strips reduces gradually from the center of the roller ring to two ends of the roller ring, and the temperature of a high temperature oil lowers after the oil is conducted to the roller ring, reaches the highest at positions close to the two ends of the roller ring, and changes gradually. The benefical effects of the tanning device are energy conservation, high temperature, high humidity and high pressure setting, and excellent precision control effects.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

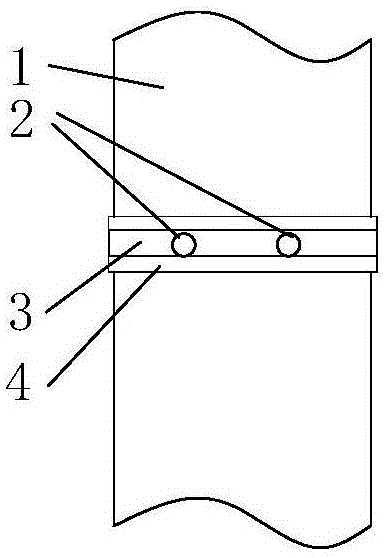

Humidifying equipment for tanning

InactiveCN105220382AGood precision controlTextile treatment machine arrangementsTextile treatment by spraying/projectingElectricityEngineering

The invention discloses humidifying equipment for tanning. The humidifying equipment comprises a spraying pipe having two sealed ends and arranged over cloth. An inlet is formed in center of the spraying pipe; the inlet is communicated with a ultrasonic wave water atomization generator; a plurality of nozzles are arranged on the pipe wall of the spraying pipe; the plurality of nozzles are arranged as follow: the closer the nozzles is to the center of the spraying pipe, the greater the distance is; the distance is the smallest when the nozzles are close to two ends of the spraying pipe; the distance is gradually changed; when cloth passes under the nozzles, the two ends of the cloth have high humidity due to the contact with the atomization air; the center of the cloth has low humidity; the humidity is gradually changed; a cover is fixed on the spraying pipe; and the cover is in a horn shape and forms humidifying areas together with the cloth. Atomization air diffusion can be reduced by the use of the technical scheme; a place where the cover is close to the center of the spraying pipe is provided with two separation plates; a non-humidifying area is formed between the two separation plates; no nozzles are arranged in the non-humidifying area; and the inlet is communicated with spraying holes of the two humidifying areas. The beneficial effects of the humidifying equipment for tanning are that the humidifying area is electricity-water-saving; humidifying and crinkle-removing can be conducted at different stages; and great and accurate control can be achieved.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Efficient leather manufacturing equipment achieving segmented wrinkle removal

InactiveCN105064052AReasonable structureLow costTextiles and paperHigh humidityPulp and paper industry

The invention discloses efficient leather manufacturing equipment achieving segmented wrinkle removal. The efficient leather manufacturing equipment comprises a heating roller, an impression roller, a humidification box, a steam nozzle communicated with an ultrasonic water atomization generator, a steam insulation plate and a barrier ring. The steam insulation plate is in an arc shap, and is arranged in the humidification box, humidification space is defined by the steam insulation plate, the humidification box and cloth, the two ends of the steam insulation plate are far away from the mounting face of the steam nozzle of the humidification box, and the center of the steam insulation plate is near to the mounting face of the steam nozzle of the humidification box. When the cloth penetrates through the humidification space, the two ends of the cloth are in contact with atomization steam for a long time. The barrier ring is composed of a plurality of circumferential bars identical in length and at least two axial bars, the barrier ring is arranged by being closely attached to the inner wall of a roller ring of the heating roller, the center intervals of the adjacent circumferential bars are the same, the widths of the circumferential bars are gradually reduced from the center of the roller ring to the two ends of the roller ring, the temperature of high-temperature oil is reduced when the high-temperature oil is conducted to the roller ring from the barrier ring, the temperature of the positions close to the two ends of the roller ring is high, and the temperature gradually changes. The efficient leather manufacturing equipment has the advantages of saving heat energy and water, achieving high-temperature high-humidity high-pressure setting and being good in precise control effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Non-oriented silicon steel hot rolled plate rolling method controlled through silicon equivalent

InactiveCN102921725BGood precision controlControl precisionProfile control deviceMetal rolling arrangementsMolten steelLiquid steel

Provided is a non-oriented silicon steel hot rolled plate rolling method controlled through silicon equivalent. The steps of the method are that blanks are formed through smelting and continuous casting; the silicon equivalent is determined according to liquid steel end composition; phase-transition temperature is determined; the casting blank heating temperature range is determined; rolling is carried out; conventional reeling up is carried out for preparation. According to the silicon equivalent computational formula of the non-oriented silicon steel hot rolled plate rolling method controlled through the silicon equivalent, the rolling phase-transition temperature range can be accurately grasped, accurate rolling technology can be achieved, so that the temperature during the rolling process effectively avoids the phase-transition temperature, and accordingly the accuracy of the plate shape is improved to more than 98% from the original accuracy of 95%, the accuracy of the width can be well controlled, the rejection rate of rolling is lowered to less than 0.75% from the original rate of 3.1%, and the rolling technology parameters are easy and quick to obtain.

Owner:武汉钢铁有限公司

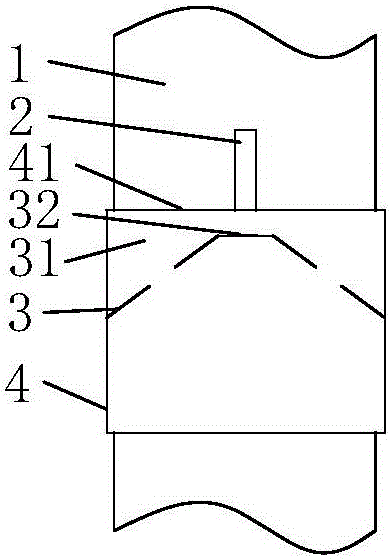

A raw material weighing device for the manufacture of porcelain insulators

ActiveCN112129393BGood precision controlAccurate weighingOscillations damping for weighingGrain treatmentsElectric machineProcess engineering

The invention discloses a raw material weighing device for the manufacture of porcelain insulators, which comprises a bottom plate, two sleeves are symmetrically and fixedly connected to the upper surface of the bottom plate, and a first spring is fixedly connected to the inner bottom wall of the sleeve. The end of the first spring far away from the sleeve is fixedly connected with a first support rod, and the outer side wall of the first support rod is slidably connected to the inner side wall of the sleeve; the stirring rod is driven by a motor to break the raw materials, and the The upper grinding head and the lower grinding head grind the raw materials further, so that it is convenient to control the accuracy of raw material addition. The stability of the electronic scale can be adjusted by rotating the fixing bolt, so that the weighing of the electronic scale is more accurate. Through the setting of the second spring, the first There is a shock-absorbing effect between the second tray and the first tray. When the operator places large-volume raw materials, it can slow down the sudden downward pressure of the second tray, thereby avoiding damage to the electronic scale.

Owner:萍乡市华瑞电瓷电器有限责任公司

Efficient ironing equipment based on synthetic leather processing

InactiveCN105155182BReasonable structureLow costTextile treatment containersTextile shapingWater savingHigh humidity

The invention discloses efficient ironing equipment based on synthetic leather processing. The efficient ironing equipment comprises a heating roller, a pressure applying roller, a humidification box, steam nozzles communicated with an ultrasonic-wave water atomization generator as well as steam isolating plates, wherein the arc-shaped steam isolating plates are mounted in the humidification box; humidification space defined by the steam isolating plates, the humidification box and fabric can meet the following requirements: when the fabric penetrates through the humidification space, the time when two ends of the fabric are contacted with atomized steam is long, and the time when positions, close to the center of the fabric, of the fabric is contacted with the atomized steam is short; the heating roller comprises a round heat-collection barrel which comprises a hollow body and a plurality of heat-collection pieces arranged on the inner wall of the hollow body, the outer surface of the hollow body is tightly attached to the inner wall of a roller ring, each heat-collection piece adopts a structure of symmetrical double triangles, apexes of the double triangles are close to the center of the hollow body, the round heat-collection barrel can absorb heat from high-temperature oil, the temperature of positions close to two ends of the roller ring is high, and the temperature changes gradually. The efficient ironing equipment based on synthetic leather processing has the benefits of heat energy saving, water saving, high-temperature, high-humidity and high-pressure setting and good accuracy control effect.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Fast ironing equipment for tanning

The invention discloses a quick ironing device for leather making, which comprises: a heating roller; a pressure roller; a nozzle connected to an ultrasonic water atomization generator, located above the cloth, and several nozzles are arranged on the wall of the nozzle. Nozzle holes, the distance between the centers of the several nozzle holes is the same, the area of the nozzle holes near the two ends of the nozzle is larger than the area of the nozzle holes near the center of the nozzle and changes gradually, when the cloth passes under the nozzle holes, the two ends of the cloth contact the atomized vapor The humidity is high, and when it is close to the center of the cloth, the humidity in contact with the atomized vapor is low; the heating roller includes: a fence ring, which is composed of a plurality of circumferential strips with the same width and length and at least two axial strips, the fence circle It is installed close to the inner wall of the roller ring, wherein the distance between the circumferential strips near the two ends of the roller ring is greater than the distance between the circumferential strips near the center of the roller ring, and the distance changes gradually. The fence ring blocks the heat absorption of the roller ring. The beneficial effects of the invention are: saving heat and water, high temperature, high humidity and high pressure setting, and good effect of precise control.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

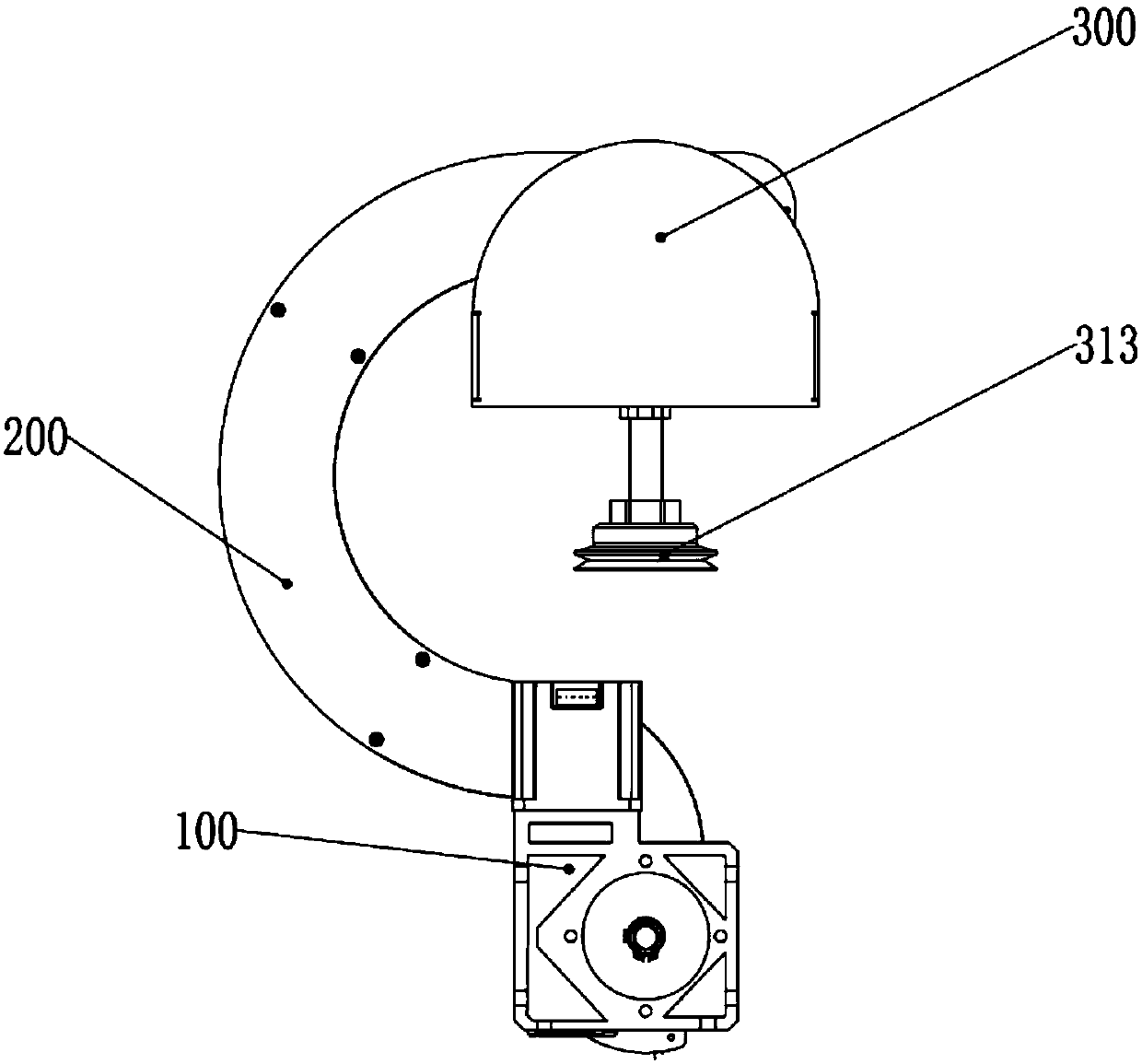

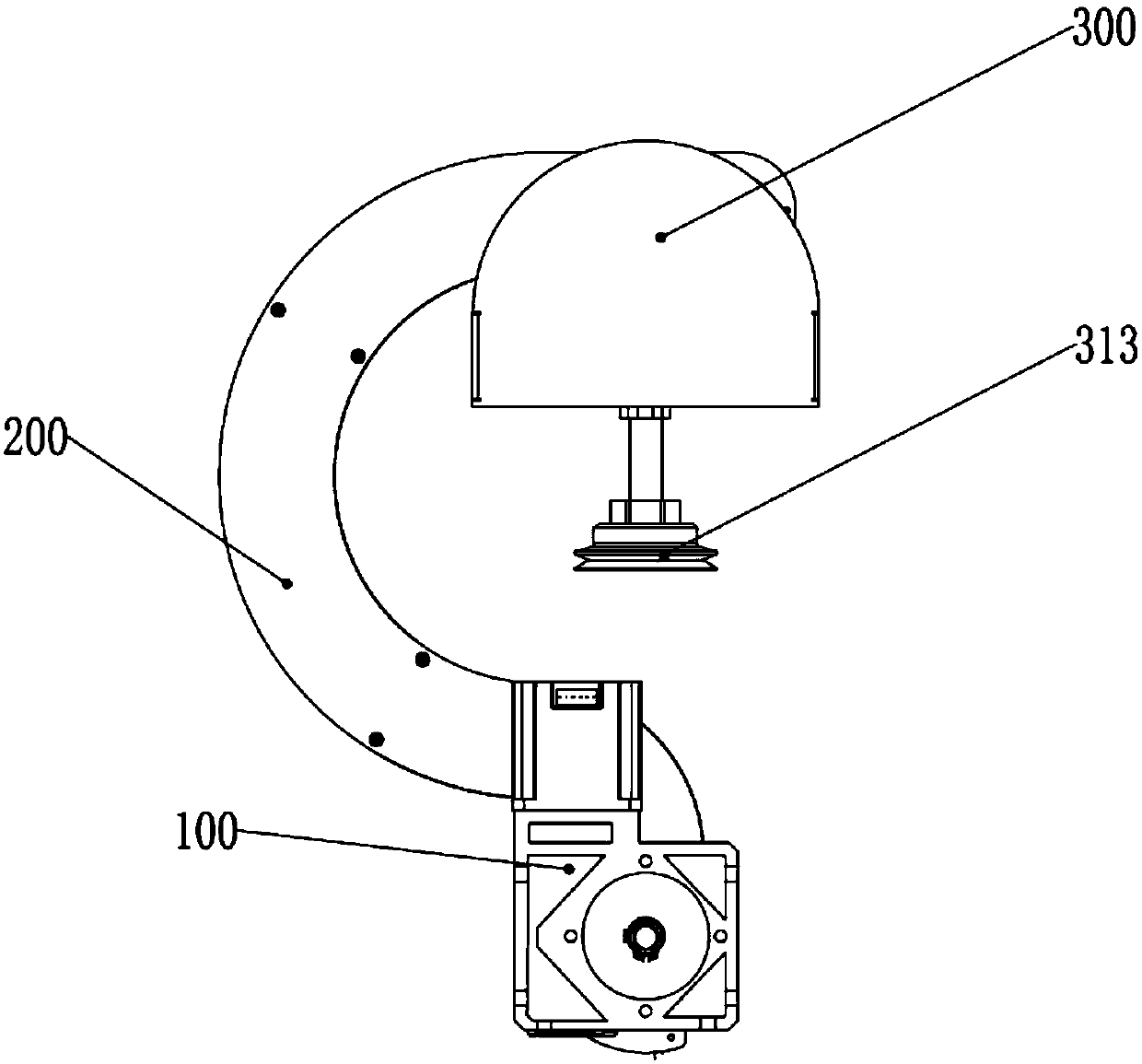

Sucker bowl taking device with laser detection control

ActiveCN111319966AGood suction freedomGood precision controlConveyorsApparatus for dispensing fluids/granular materialsLaser rangingElectric machinery

The invention relates to the technical field of kitchen equipment, in particular to a sucker bowl taking device with laser detection control. The sucker bowl taking device comprises a control box assembly, a swing arm assembly, an electromagnet and a motor assembly, wherein the swing arm assembly comprises a swing arm body; and the control box assembly comprises a control box shell, a swing rotating shaft, a vacuum pump, a sucker and a laser ranging controller, the control box assembly can swing relative to the swing arm assembly, and the vacuum pump communicates with the sucker through an airpipe. The sucker bowl taking device has larger sucking taking range, and the horizontal rotating radius is small, so that the rotating gravity center is concentrated and stabler; and the control boxassembly can swing within a certain range to cater to inclined bowls, and the laser ranging controller and the electromagnet enable the swing controllability of the control box to be higher, so that the sucker bowl taking device has good sucking taking freedom degree and accurate controllability, the bowl sucking taking operation is more flexible and rapid, and bowl sucking taking and moving are more accurate and stabler.

Owner:北京快端科技有限公司

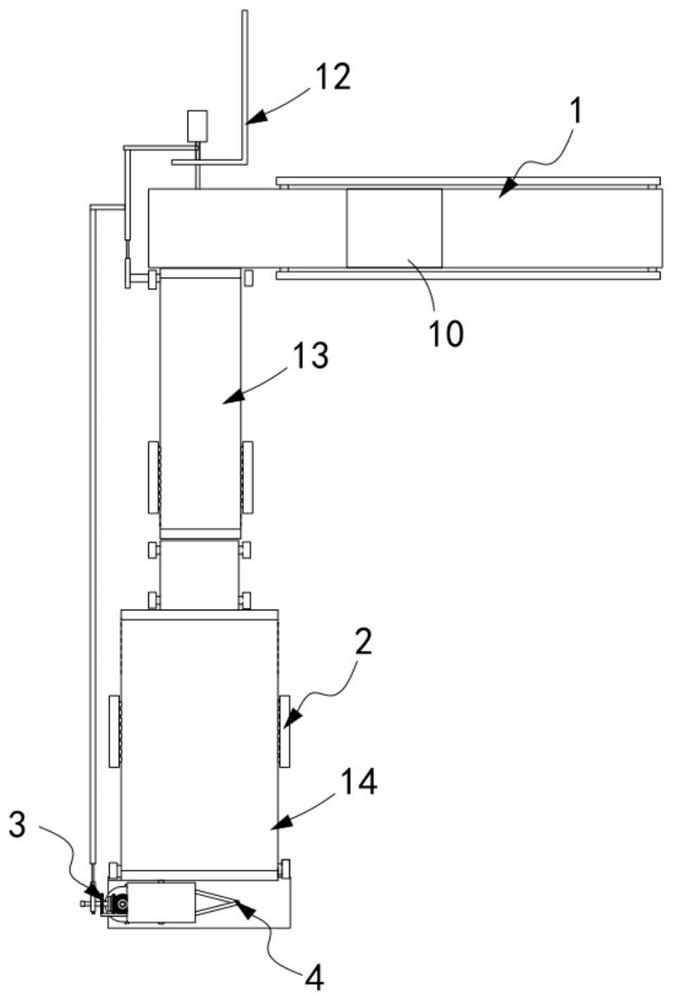

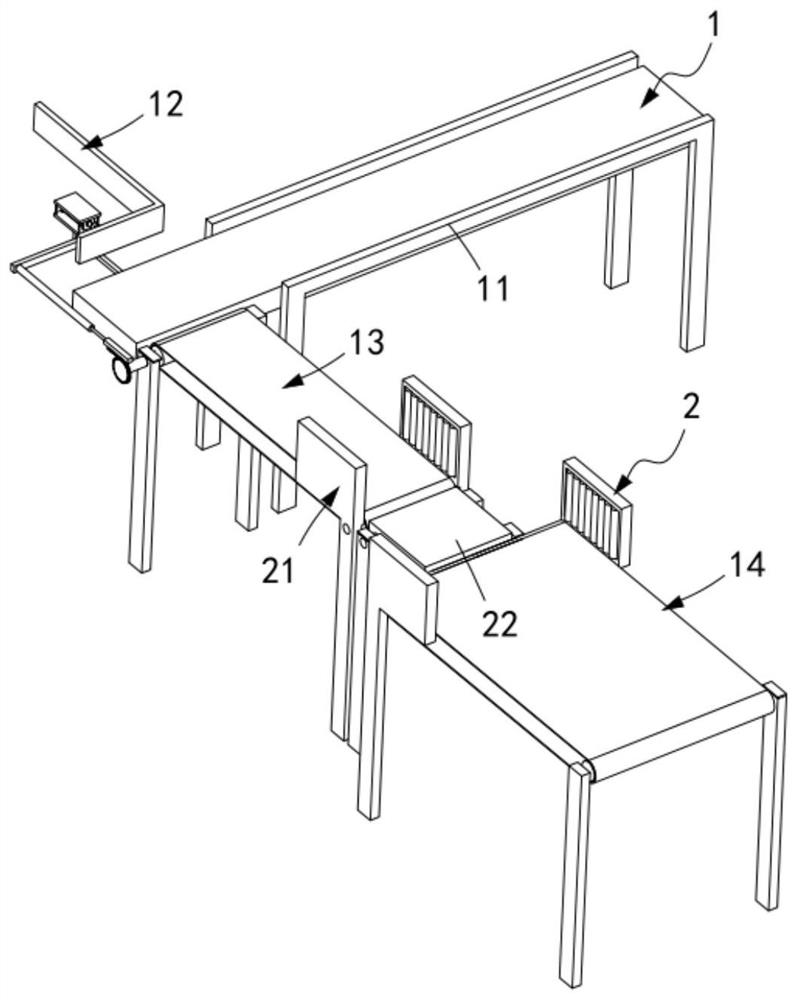

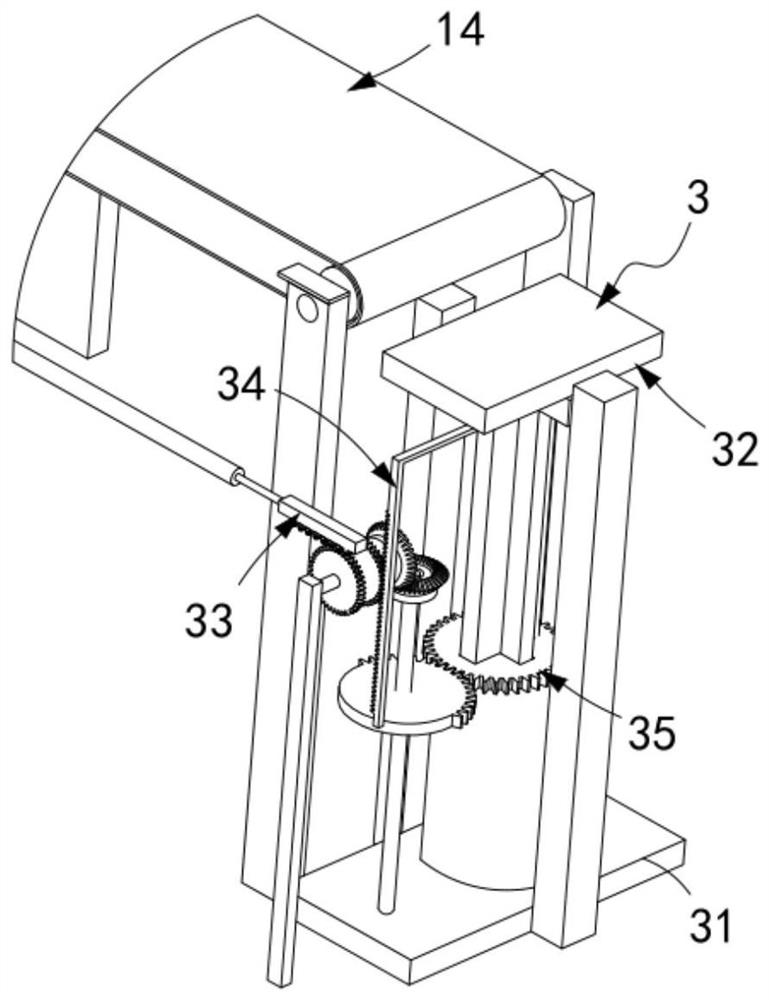

Full-automatic stacking device for sintered bricks

InactiveCN112079124AHigh degree of automationHigh linkageDischarging arrangementStacking articlesBrickEngineering

The invention relates to a full-automatic stacking device for sintered bricks. The full-automatic stacking device for sintered bricks comprises a conveying mechanism, a grinding mechanism, a stackingmechanism and clamping mechanisms, wherein the conveying mechanism comprises a rack, a horizontal pushing assembly, a first conveying mechanism and a second conveying mechanism; the grinding mechanismis located between the first conveying assembly and the second conveying assembly; the stacking mechanism comprises a supporting frame, a receiving disc assembly, a first transmission assembly in synchronous transmission with the horizontal pushing assembly, a downward moving assembly driven by the first transmission assembly to conduct transmission and used for driving the receiving disc assembly to move downwards in the vertical direction, a rotating assembly for driving the receiving disc assembly to intermittently rotate, and a lateral moving assembly reciprocating in the horizontal direction, and the receiving disc assembly, the first transmission assembly, the downward moving assembly, the rotating assembly and the lateral moving assembly are installed on the supporting frame; and the two clamping mechanisms are symmetrically arranged on the two sides of the receiving disc assembly, and fixedly installed on the receiving disc assembly. The technical problems that during multi-layer stacking work, a workbench cannot naturally descend, and meanwhile, during multi-group stacking work in the horizontal direction, the horizontal space of a workshop is occupied are solved.

Owner:李兵

Water-saving and electricity-saving ironing equipment for tanning

InactiveCN105177891BReasonable structureLow costTextile treatment by spraying/projectingTextile shapingWater savingHigh humidity

The present invention discloses a water-saving and power-saving ironing device for tanning. The ironing device comprises a heating roller, an impression roller assorted with the heating roller, and a spray pipe communicated with an ultrasonic wave water atomization generator, wherein a plurality of spray holes are formed in a pipe wall of the spray pipe and are in the following arrangement, gaps close to the center of the spray pipe are the largest while gaps close to two ends of the spray pipe are the smallest, the gaps change gradually, and when cloth penetrates below the spray holes, humidity of two ends of the cloth contacting atomized steam is high while that of the center of the cloth contacting the atomizd steam is low, and the humidity changes gradually; the heating roller comprises a fence ring composed of a plurality of circumferential strips of the same width and length and at least two axial strips, the fencing ring is installed close to an inner wall of a roller ring, distance between circumferential strips close to the two ends of the roller ing is larger than that between circumferential strips close to the center of the roller ring, the distance changes gradually, and the fence ring prevents the roller ring from absorbing heat. The benefical effects of the ironing device are energy conservation, high temperature, high humidity and high pressure setting, and excellent precision control effects.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

Quick ironing equipment for tanning

The invention discloses quick ironing equipment for tanning. The quick ironing equipment for tanning comprises a heating roller and an impression roller. A spray pipe communicated with an ultrasonic water atomizing generator is located above cloth. The pipe wall of the spray pipe is provided with a plurality of spray holes, the center intervals of the spray holes are the same, the areas of the spray holes close to the two ends of the spray pipe are larger than the areas of the spray holes close to the center of the spray pipe and gradually change. When the cloth penetrates through the position below the spray holes, the humidity of the two ends of the cloth in contact with atomizing steam is high, and when the center of the cloth is approached, the humidity of the cloth in contact with the atomizing steam is low. The heating roller comprises a fence ring, the fence ring is composed of a plurality of peripheral strips which are the same in both width and length and two or more axial strips, the fence ring is tightly attached to the inner wall of a roller ring, the interval distances of the peripheral strips close to the two ends of the roller ring are larger than the interval distances of the peripheral strips close to the center of the roller ring, the interval distances gradually change, and the fence ring prevents the roller ring from absorbing heat. The quick ironing equipment for tanning has the advantages that heat energy and water are saved, high-temperature high-humidity high-pressure shaping is achieved, and the accurate control effect is good.

Owner:ZHEJIANG SIAP KANGDA SYNTHETIC LEATHER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com