Water-saving and power-saving wrinkle removal equipment for synthetic leather processing

A synthetic leather and wrinkle-removing technology, which is applied in textiles and papermaking, fabric surface trimming, spray/jet textile material treatment, etc., can solve the problems of increasing energy consumption, not easy to flatten the cloth, and unable to apply uniform pressure on the cloth, etc., to achieve Reasonable structure, low cost, good effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

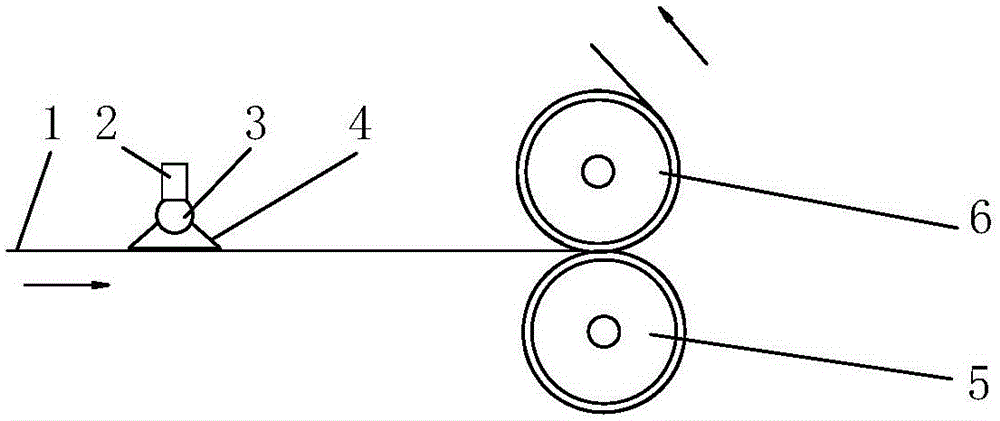

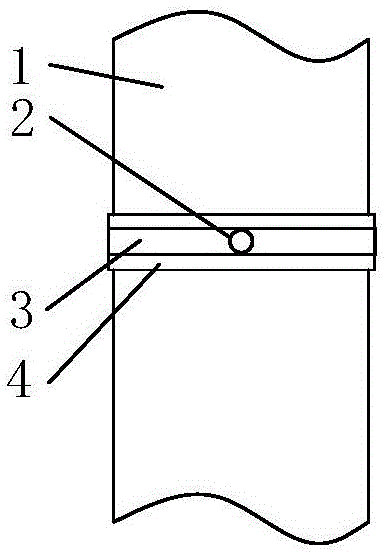

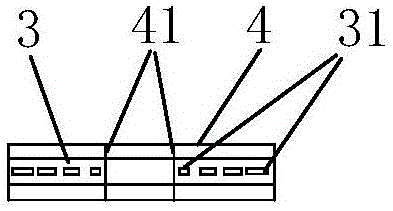

[0032] Now in conjunction with accompanying drawing, the present invention will be further described:

[0033] As shown in the figure, a water-saving and power-saving synthetic leather processing and wrinkle-removing equipment includes:

[0034] heating roller 6;

[0035] The pressure roller 5 cooperates with the heating roller 6 to pressurize and heat the cloth 1;

[0036] The heating roller 6 includes:

[0037] The roller ring 61, the two roller end faces 67 connected with the roller ring 61 and the roller shaft 64 passing through the center of the roller end face 67, the roller shaft 64 is installed on the frame through the bearing 66;

[0038] An inner cylinder 62, the outer surface of which is provided with a first insulating material;

[0039] The heating wire 63 is wound outside the first insulating material on the inner cylinder 62. The heating wire 63 near the two ends of the inner cylinder 62 is densely wound, and the wire 63 near the center of the inner cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com