Water-saving and power-saving leather making equipment realizing segmented crease removal

A wrinkle removal and equipment technology, applied in textiles and papermaking, etc., can solve the problems of increased energy consumption, difficulty in flattening the cloth, and inability to apply uniform pressure on the cloth, etc., and achieve the effects of reasonable structure, good precision control effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

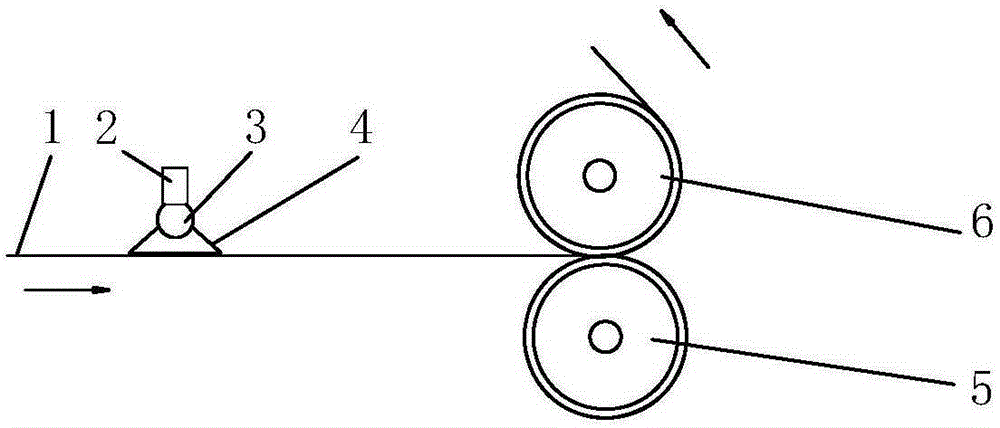

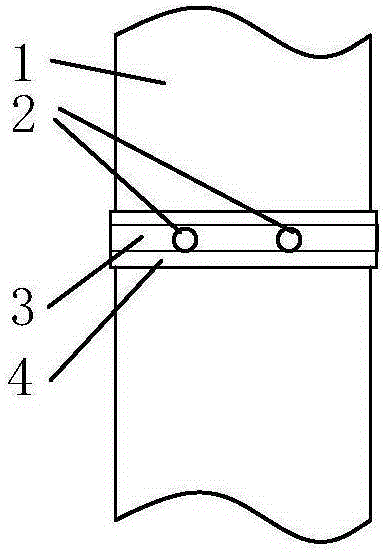

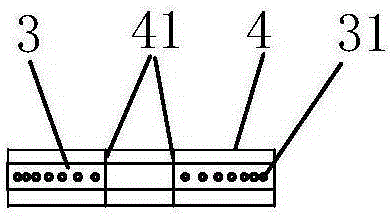

[0027] Now in conjunction with accompanying drawing, the present invention will be further described:

[0028] As shown in the figure, a segmented wrinkle-saving water-saving and power-saving tanning equipment includes:

[0029] The heating roller 6 is composed of a roller ring 61, two roller end faces 62 and a roller shaft 64. The roller shaft 64 is installed on the frame through a bearing 63, and the high-temperature oil 67 in the heating roller 6 communicates with the heating oil tank through an oil pump; The central inlet 641 of the roller shaft 64 flows in, the inner outlet hole 651 of the roller shaft 64 flows out into the heating roller 6, and then flows out from the inner inlet hole 652 of the roller shaft 64 through the center outlet 642 of the roller shaft 64, and the roller shaft 64 and the oil pipeline The connections can be made with swivel joints.

[0030] The pressure roller 5 cooperates with the heating roller 6 to pressurize and heat the cloth 1;

[0031] Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com