System and method for slide guiding drilling well control with adaptability

A sliding-steering, self-adaptive technology, applied in the direction of self-adaptive control, general control system, control/adjustment system, etc., can solve the disturbance uncertainty of dynamic control of tool face angle, difficult to guarantee WOB and drilling speed, tool It is difficult to accurately control the face angle and other problems, so as to achieve the effect of convenient connection and integration, small changes and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

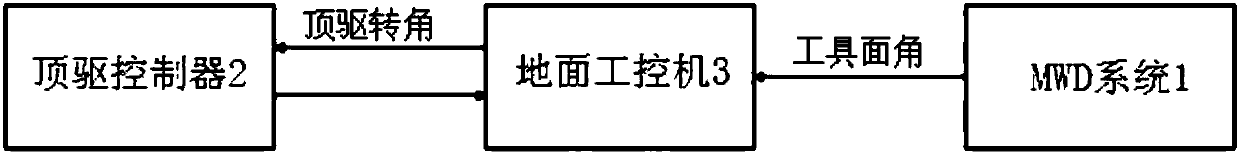

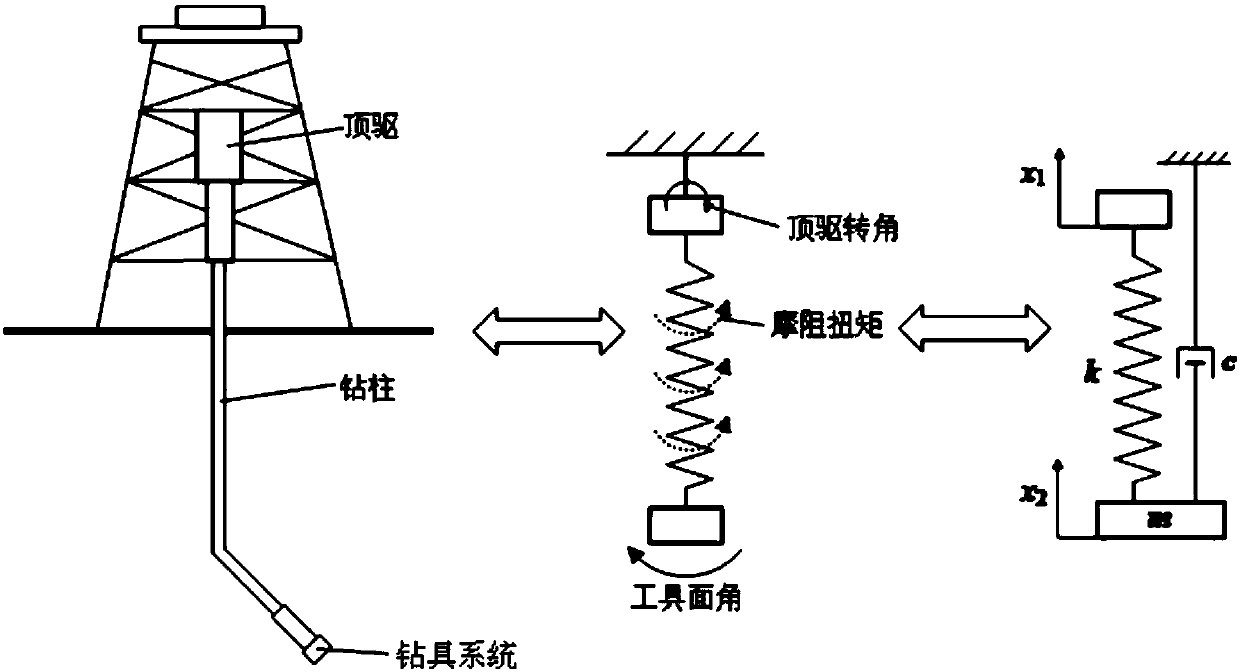

[0044] Such as figure 1 As shown, the self-adaptive slide steerable drilling control system provided by the present invention includes MWD (measurement while drilling) system 1 , top drive controller 2 and ground industrial computer 3 .

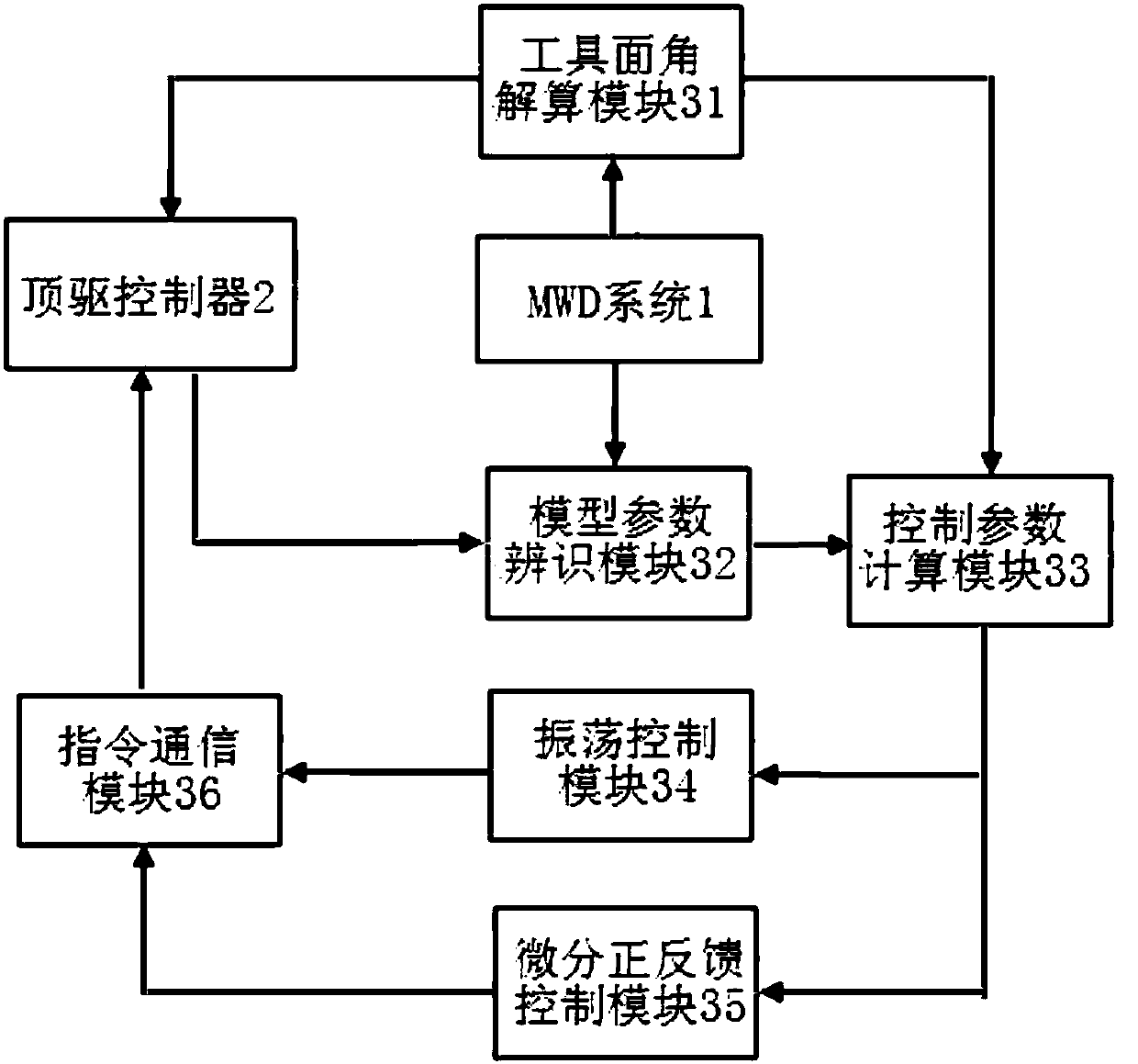

[0045] The MWD system 1 is used to measure the tool face angle of the drilling tool system in the slide steerable drilling in real time and send it to the ground industrial computer 3 . The top drive controller 2 is used to control the rotation of the top drive in the slide steerable drilling, and feed back the corresponding top drive rotation angle to the ground industrial computer 3 . The ground industrial computer 3 is used to cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com