Humidifying equipment for tanning

A humidification equipment and humidity technology, which is applied in the processing of textile material equipment configuration, textile processing machine accessories, textile material processing, etc., can solve the problems of difficult flattening of cloth, high quality of synthetic leather at both ends, and inability to spread evenly. Pressure and other problems, to achieve precise control effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

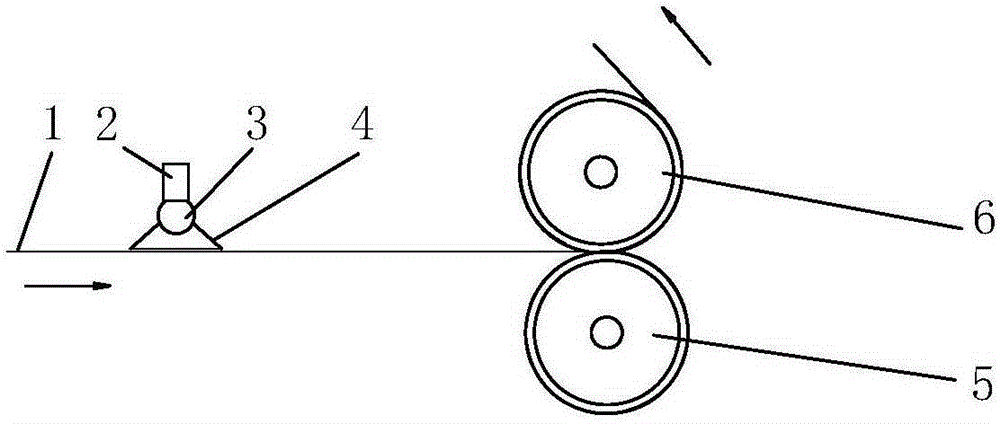

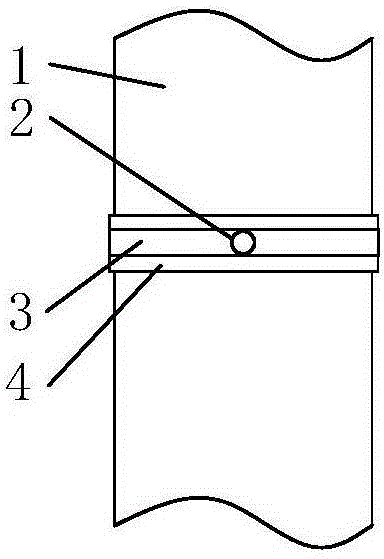

[0030] Now in conjunction with accompanying drawing, the present invention will be further described:

[0031] As shown in the figure, a humidification equipment for tanning, including:

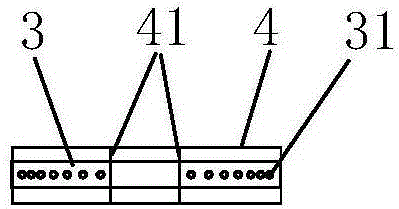

[0032] The nozzle 3 is closed at both ends, located above the cloth 1, and the center is provided with an inlet 2, and the inlet 2 is connected to the ultrasonic water atomization generator. The wall of the nozzle 3 is provided with several nozzles 31, and several nozzles 31 Arranged as follows, the distance near the center of the nozzle 3 is the largest, and the distance near the two ends of the nozzle 3 is the smallest, and the distance changes gradually. When the cloth 1 passes under the nozzle 31, the humidity of the atomized steam at both ends of the cloth 1 is high, and the cloth 1 The humidity of the center contacting the atomized vapor is low, and the humidity changes gradually.

[0033] A cover 4 is fixed on the spray pipe 3, and the cover 4 is in the shape of a trumpet and forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com