A raw material weighing device for the manufacture of porcelain insulators

A technology for weighing raw materials and porcelain insulators, applied in measuring devices, weighing, special scales, etc., can solve problems such as deviation of results, damage, no raw material weighing of electric porcelain insulators, etc., to achieve the effect of accurate weighing and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

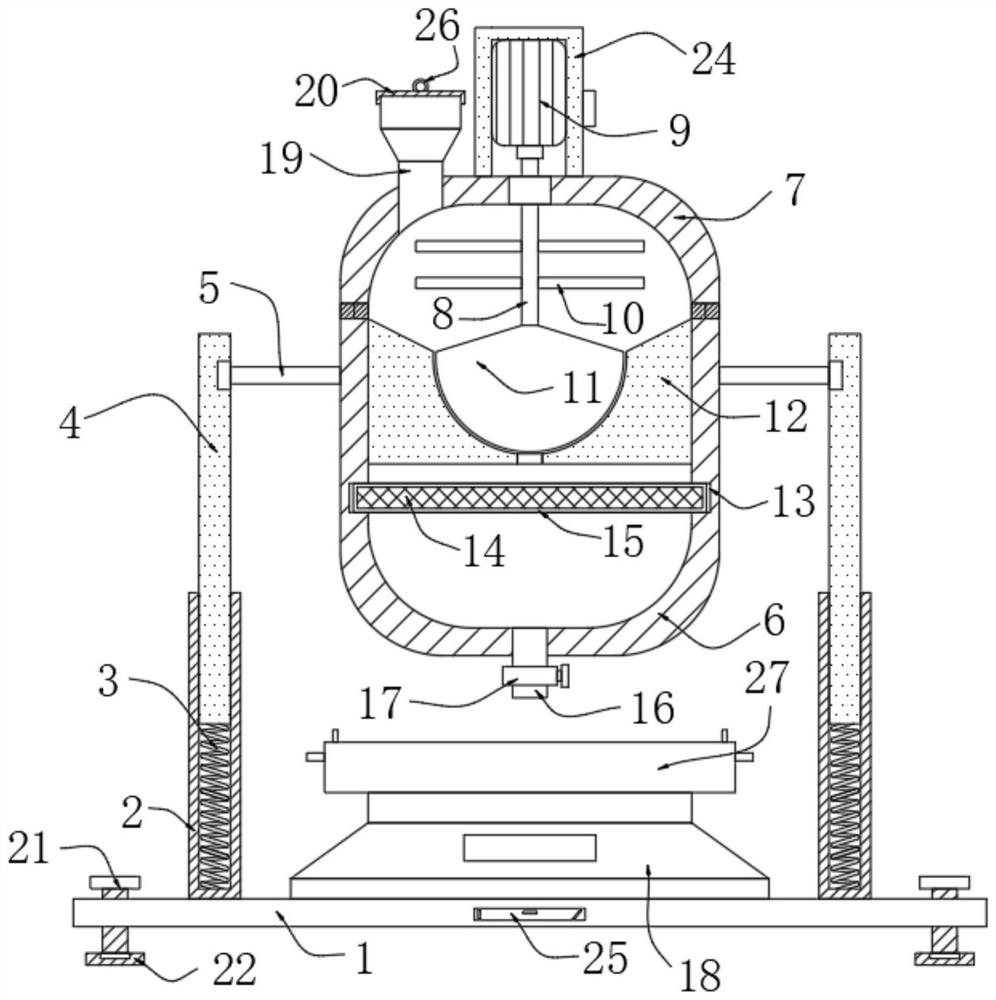

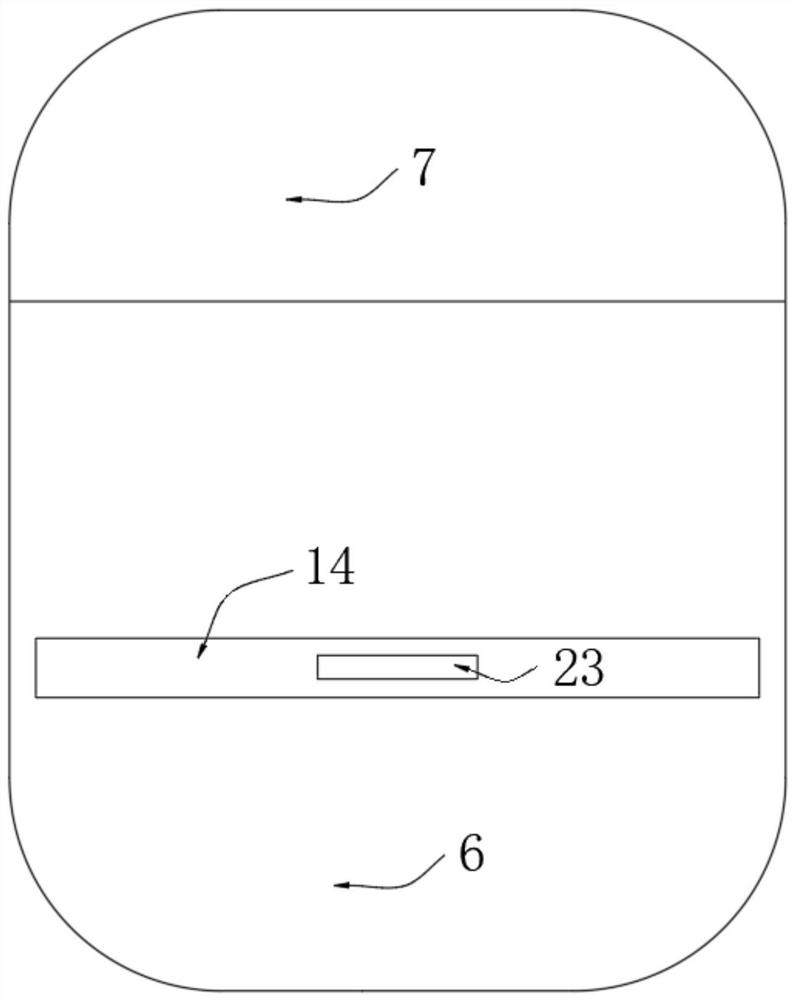

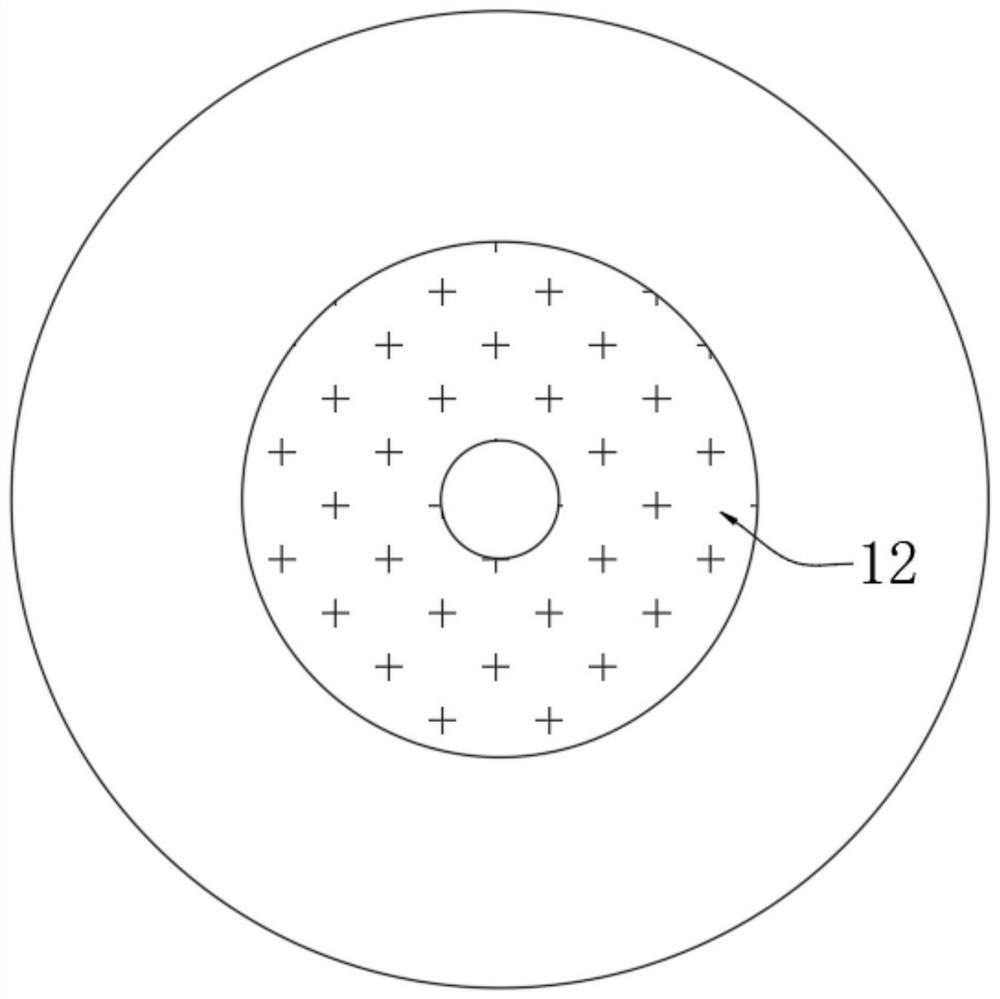

[0020] see Figure 1-5 , the present invention provides a technical solution: a raw material weighing device for the manufacture of porcelain insulators, including a bottom plate 1, the upper surface of the bottom plate 1 is symmetrically fixedly connected with two sleeves 2, and the inner bottom wall of the sleeve 2 is fixedly connected with The first spring 3, the end of the first spring 3 away from the sleeve 2 is fixedly connected with the first support rod 4, the outer side wall of the first support rod 4 is slidably connected to the inner side wall of the sleeve 2, and the outer side wall of the first support rod 4 The second support rod 5 is connected by bearing rotation, and the adjacent ends of the two second support rods 5 are fixedly connected with the first shell 6, and the top of the first shell 6 is screwed with the second shell 7, and the second shell The top of the body 7 is rotatably connected with a transmission rod 8 through a bearing, the top of the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com