Double-chamber and double-window electrolytic tank for electrochemically preparing gases

A dual gas chamber, electrochemical technology, applied in the field of electrochemical and photoelectrochemical experimental research, can solve problems affecting experimental results, etc., and achieve the effect of easy accuracy, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

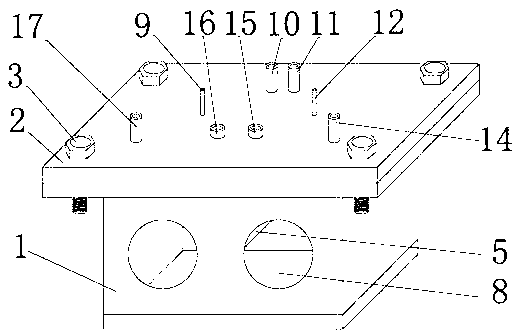

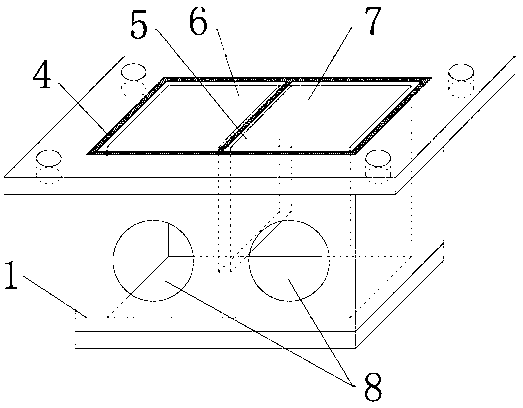

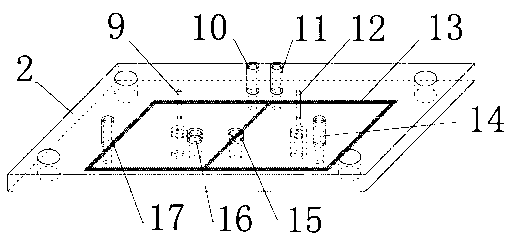

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] refer to figure 1 , an electrolytic cell with double gas chambers and double light windows for electrochemically producing gas, comprising a reaction cell 1 and a cover plate 2, the cover plate 2 is arranged at the opening of the reaction cell 1, and between the cover plate 2 and the reaction cell 1 For a detachable sealed connection, the cover plate 2 is provided with a number of connection ports, and the reaction tank 1 is provided with a partition 5, and the partition 5 divides the space in the reaction tank 1 into a working electrode reaction chamber 6 and an auxiliary The electrode reaction chamber 7 has two parts, the upper edge of the partition 5 is flush with the top surface of the reaction tank 1, the front and rear side edges of the partition 5 are sealed and connected with the front and rear inner walls of the reaction tank 1, and the lower edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com