Three-leaf rose line 3D swinging device and method of electroplating equipment

A technology of electroplating equipment and swinging device, which is applied in the electrolysis process, electrolysis components, cells, etc., and can solve the inconvenience of workpiece positioning and lifting, occupying space, tank piping, copper distribution, horizontal pulling and air extraction at the tank side Inconvenient cover installation and other problems, to meet the requirements of high-quality processing, large swing action, good effect of action consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

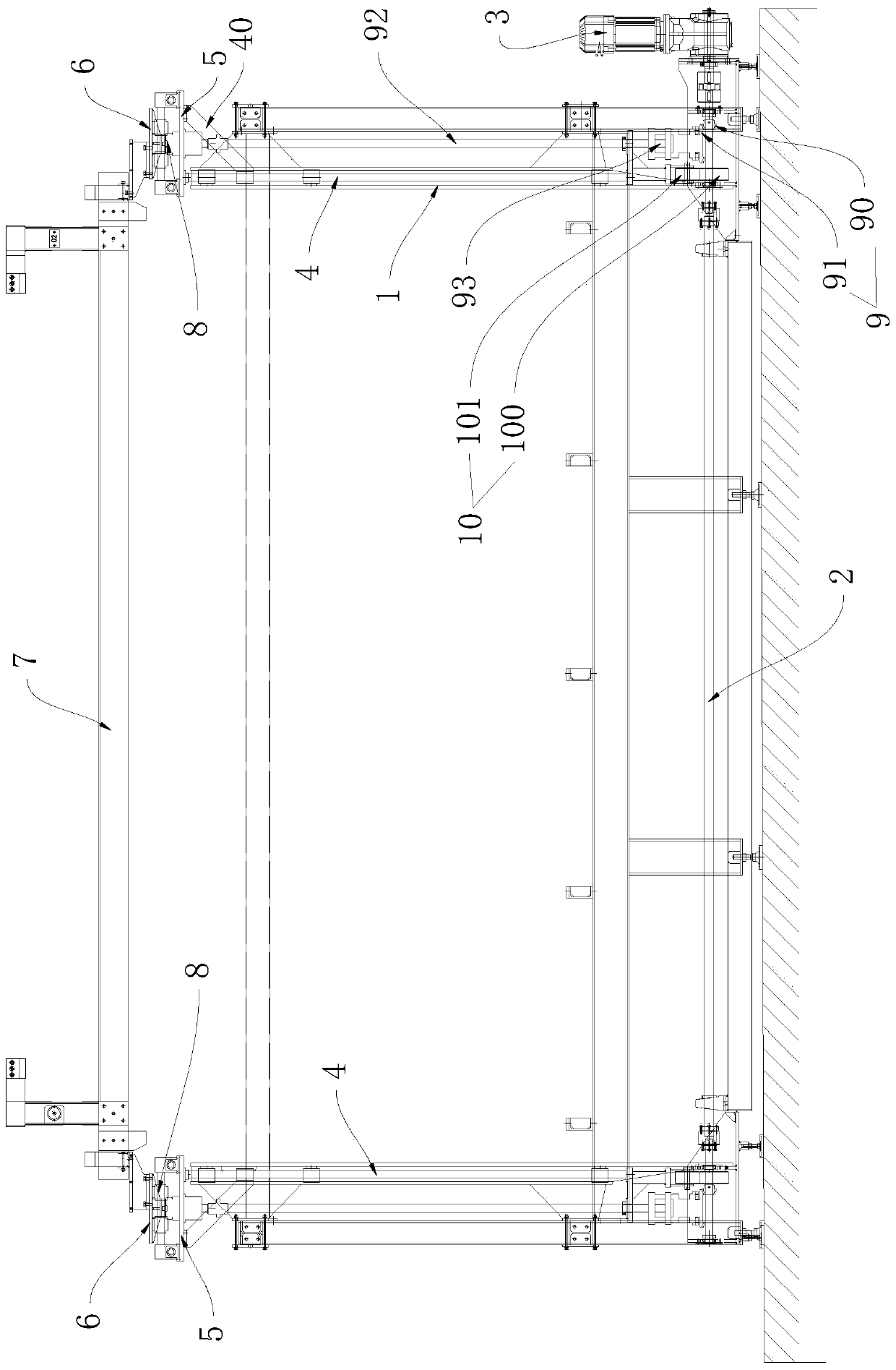

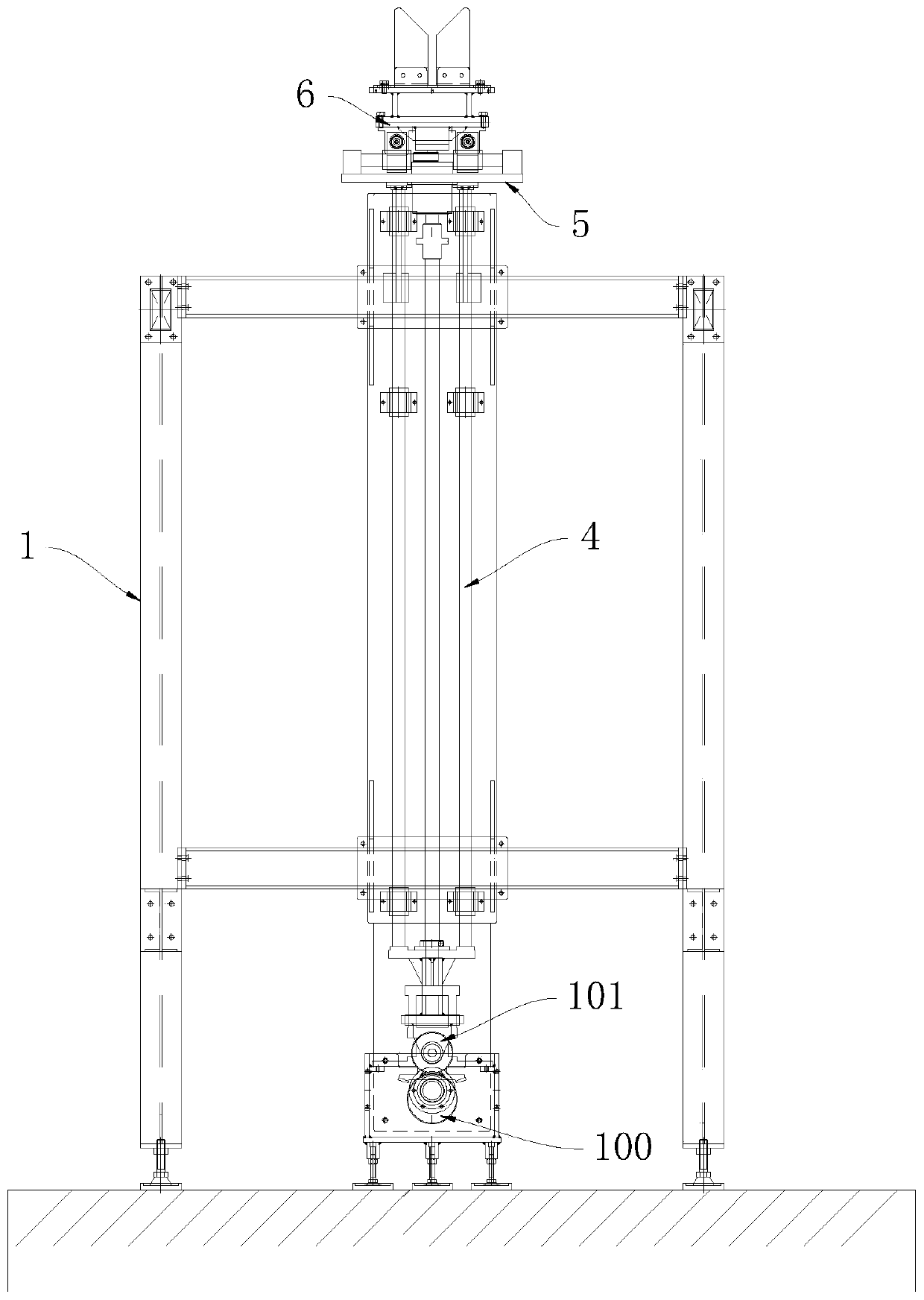

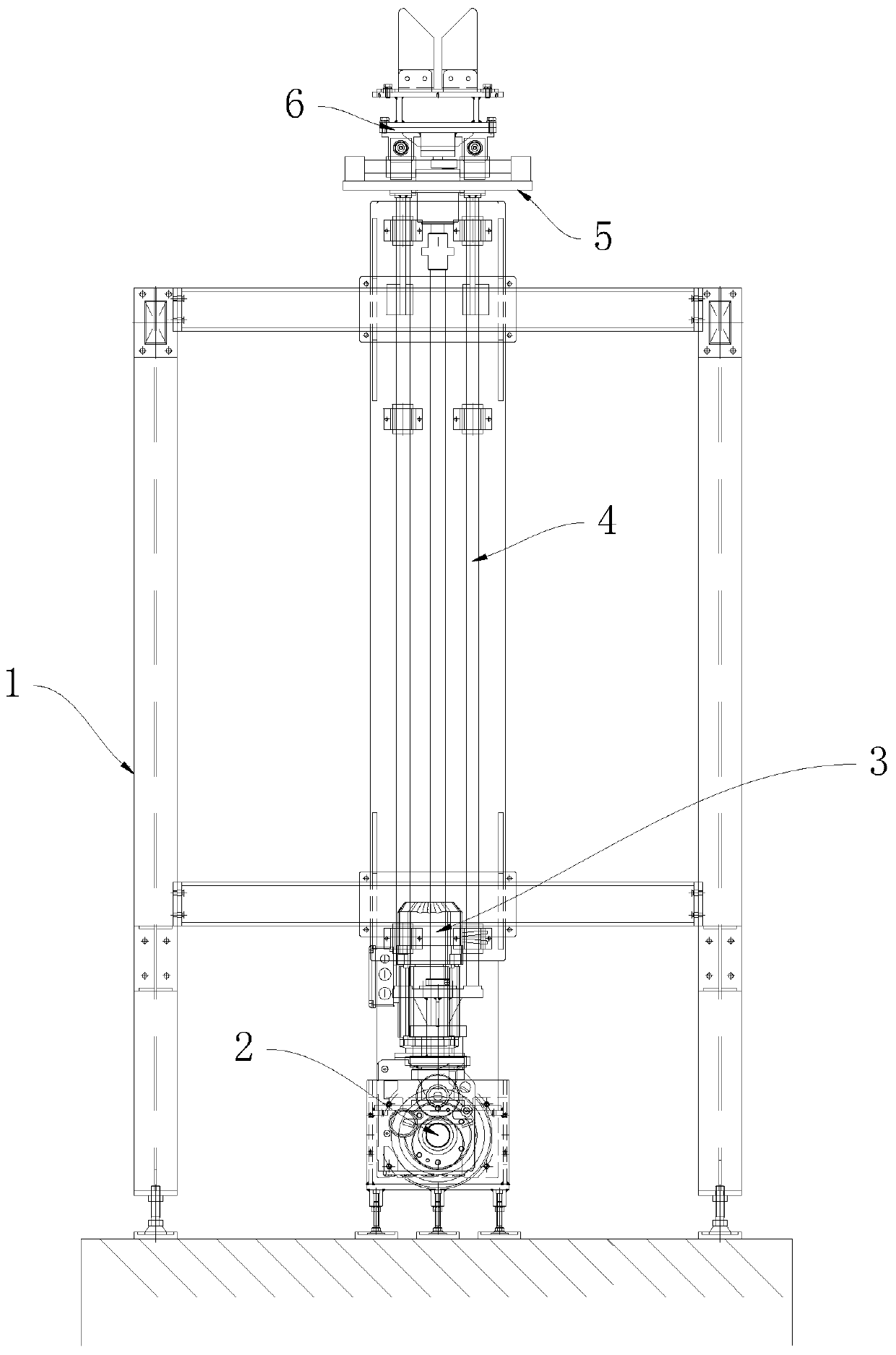

[0026] The invention discloses a three-leaf rose line 3D swing device for electroplating equipment, which combines Figure 1 to Figure 6 As shown, it includes a frame 1, the bottom of the frame 1 is provided with a main drive shaft 2 arranged horizontally, and the outer side of the frame 1 is provided with a rotary drive mechanism 3 for driving the main drive shaft 2 to run , the left and right sides of the frame 1 are respectively provided with a lifting frame 4 that can move up and down, the top of the lifting frame 4 is provided with a lifting platform 5, and the top of the lifting platform 5 is provided with a motion platform 6, and the two moving A boom 7 for installing a hanger is fixed between the platforms 6, and a cycloid mechanism 8 for driving the moving platform 6 to move according to the trefoil rose line track is provided on the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com