Gantry type multipoint grain purchasing intelligent sampling device

A sampling device and multi-point technology, which is applied in the field of gantry-type multi-point grain acquisition intelligent sampling device, can solve problems such as inseparable from manual on-site operation, inaccurate depth of cutting rod, and unavoidable direct or indirect contact of materials, etc., to achieve Avoid bending or even breaking, and overcome the effect of poor structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

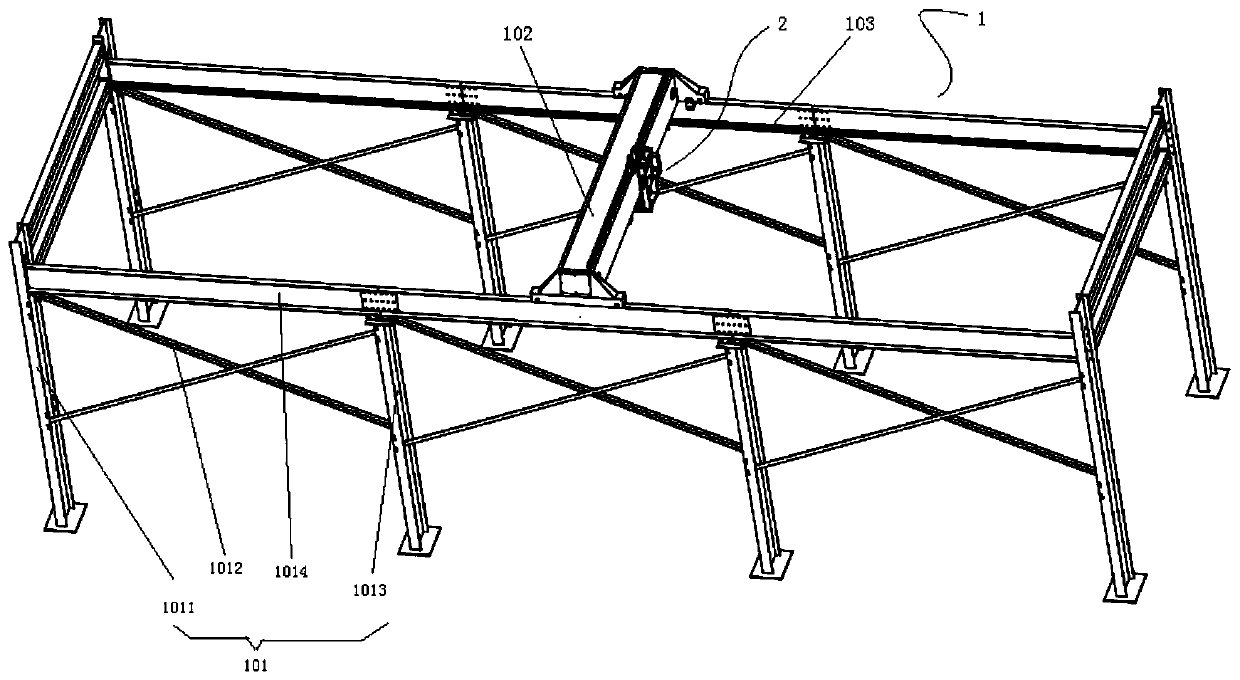

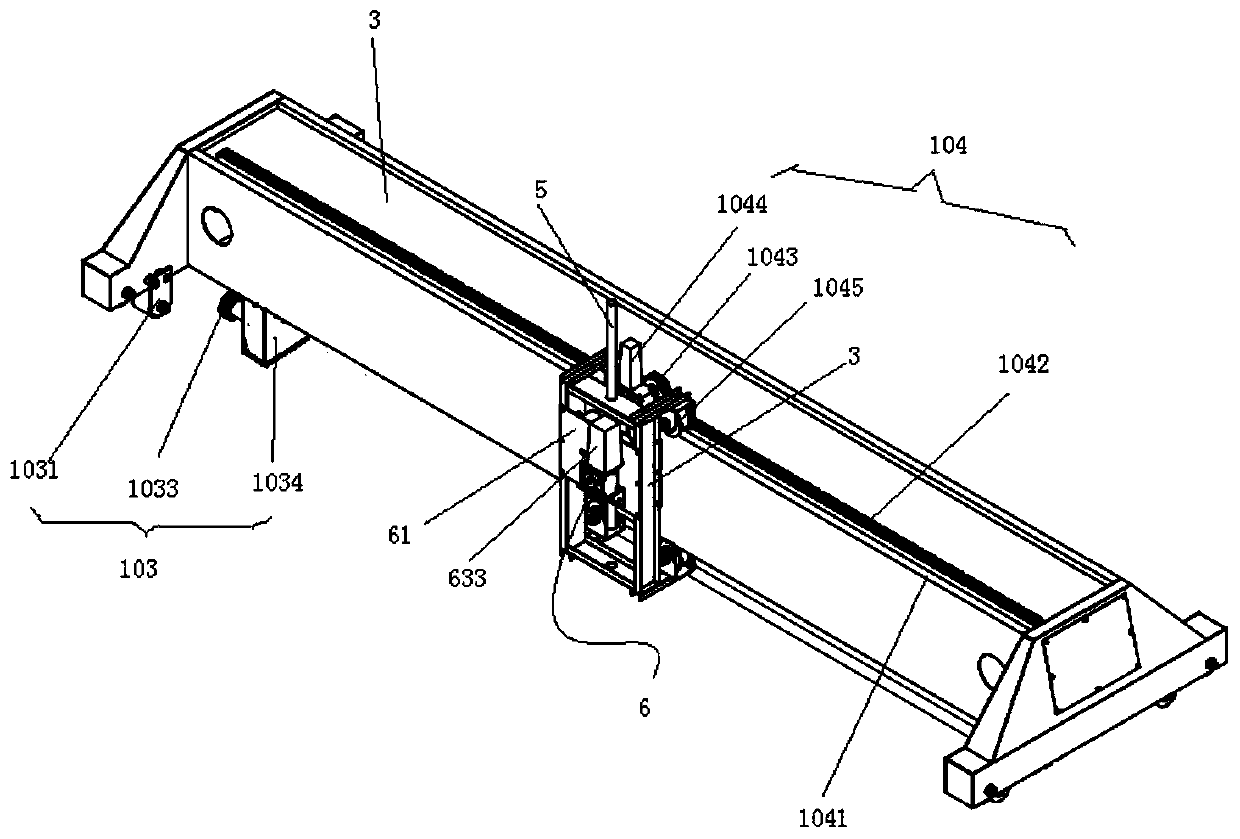

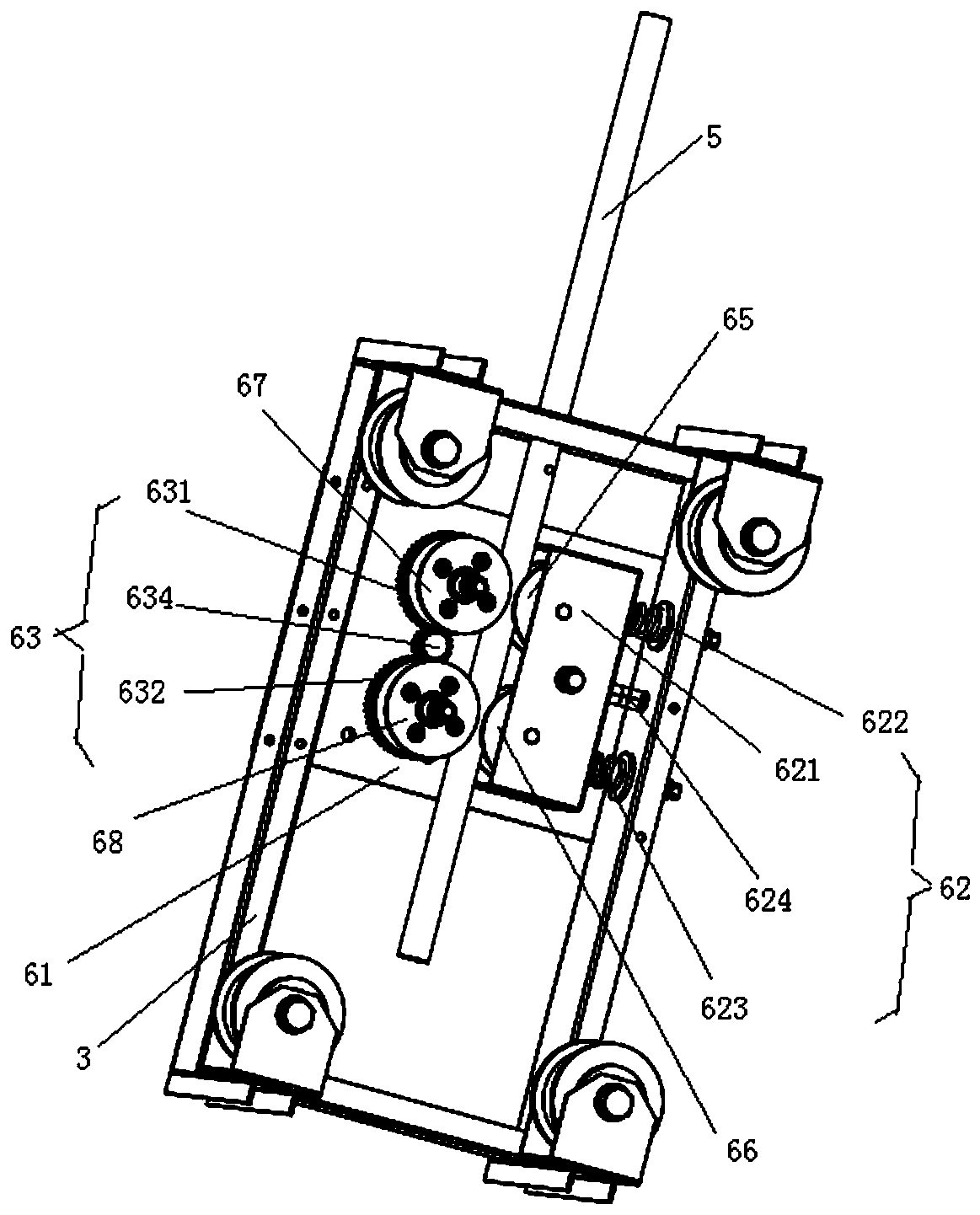

[0022] As shown in the figure: a kind of gantry type multi-point grain acquisition intelligent sampling device according to the present invention includes a sampling mechanism 2 and a gantry body 1 for driving the sampling mechanism 2 to perform plane movement, and the sampling mechanism 2 includes a The support 3 connecting the gantry body 1 and the sampling mechanism 2, the material air flow conveyor 8 connected in sequence, the sample conveying hose 4, the sample rod 5, the vertical drive device 6 and the central control device 7, the direct drive The device includes a fixed plate 61 connected to the front end of the support 3, an adjusting frame 62 arranged at the side end of the support 3, a passive sheave rotatably connected to the adjusting frame 62, a driving sheave rotatably connected to the fixed plate 61 and a fixed plate 61. The sheave driving device 63 for driving the rotation of the driving sheave, the driving sheave and the passive sheave are oppositely arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com