Aerosol generating article having improved mouth end cavity

An aerosol generation and product technology, which is applied in the manufacture of cigarettes, cigars, smoke oil filters, etc., can solve the problems of whether it is effective or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

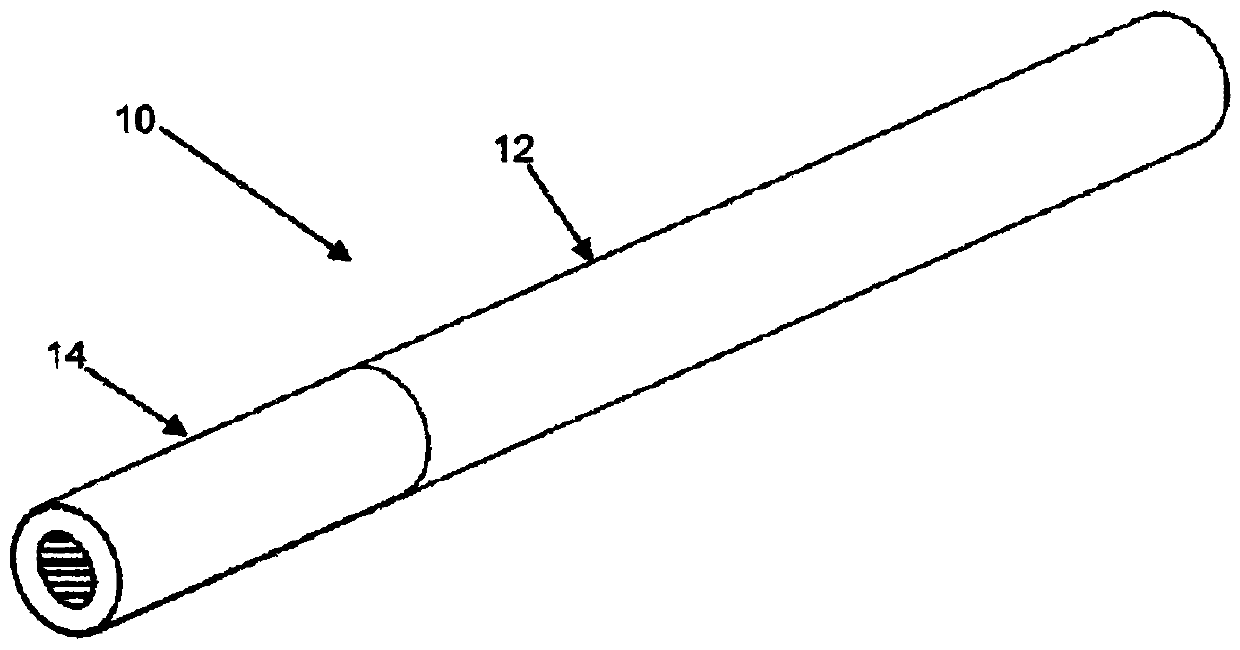

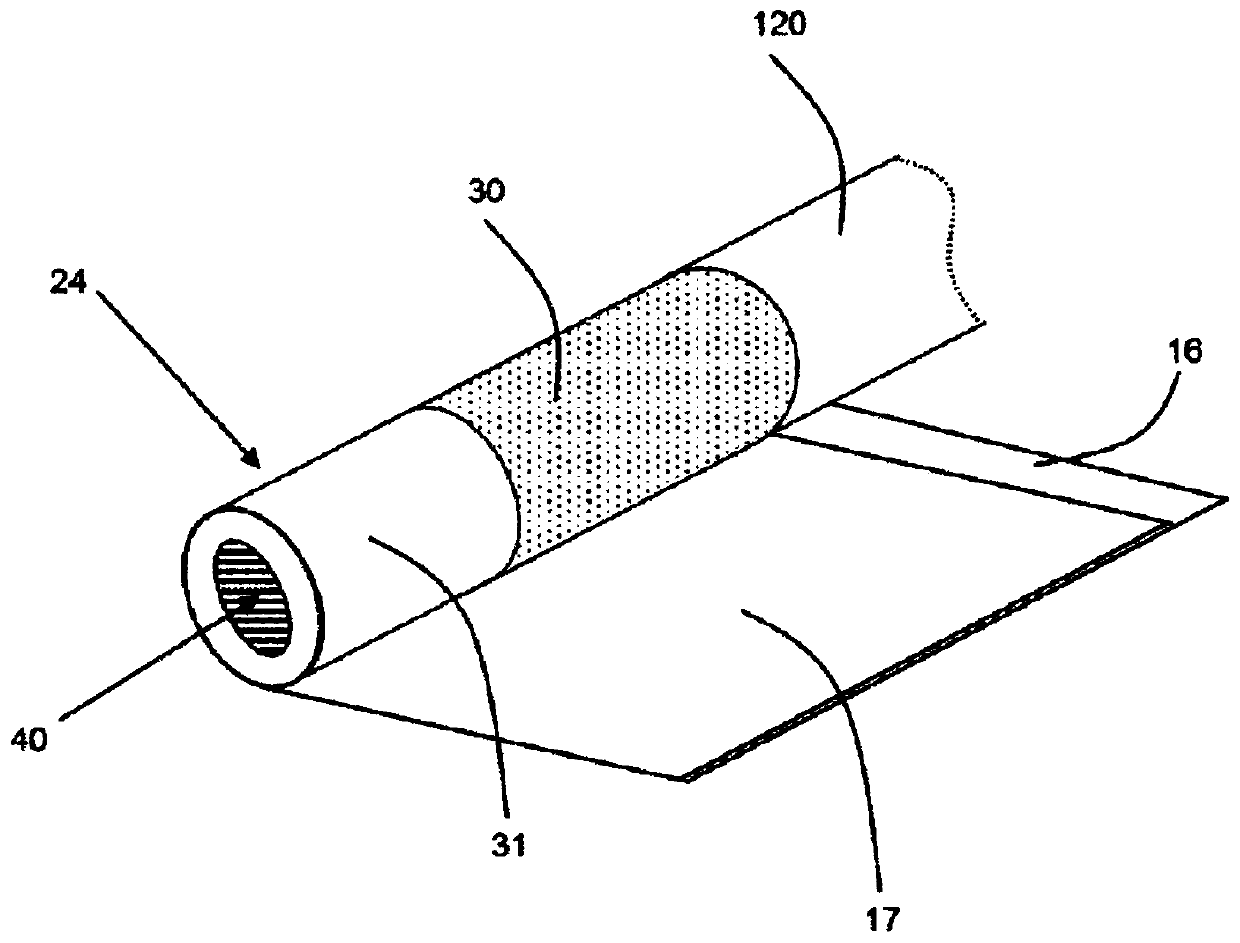

[0042] figure 1 with figure 2 An aerosol-generating article 10 according to a first embodiment of the invention is shown. The article is in the form of a smoking article. The smoking article 10 comprises an aerosol-forming substrate in the form of a wrapped rod 12 of tobacco filler. The rod 12 is attached to one end of the mouthpiece in the form of an axially aligned filter 14 . A strip of tipping paper 16 surrounds the filter 14 and a portion 120 of the tobacco wrapping rod 12 to bond the two portions of the smoking article 10 together.

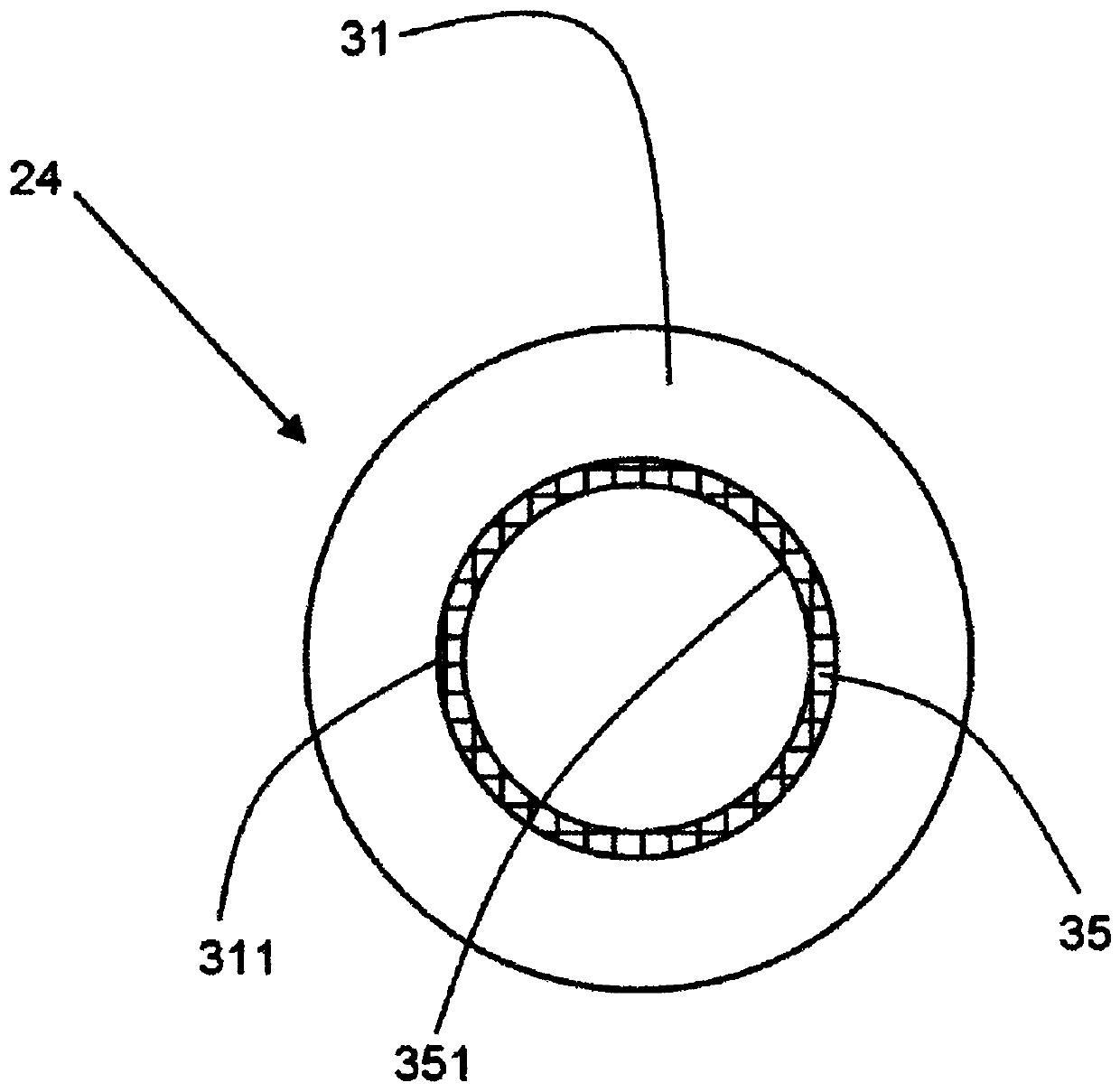

[0043] Such as figure 2 As shown, the filter 14 includes a hollow tubular section 24 . The hollow tubular section 24 comprises a hollow tube 31 of crimped fibrous material in the form of cellulose acetate tow. The hollow tubular section 24 is located at the downstream end of the filter 14 and defines a mouth end cavity 40 of the article 10 . Upstream of the hollow tubular section 24 is a filter section 30 which is also formed from a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap