Linkage mud feeding device for aluminum pot mold manufacturing

A mold and aluminum pot technology, applied in the field of aluminum pot billet, can solve the problems of poor structure, slowness, low efficiency, etc., and achieve the effect of reasonable device structure and obvious linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

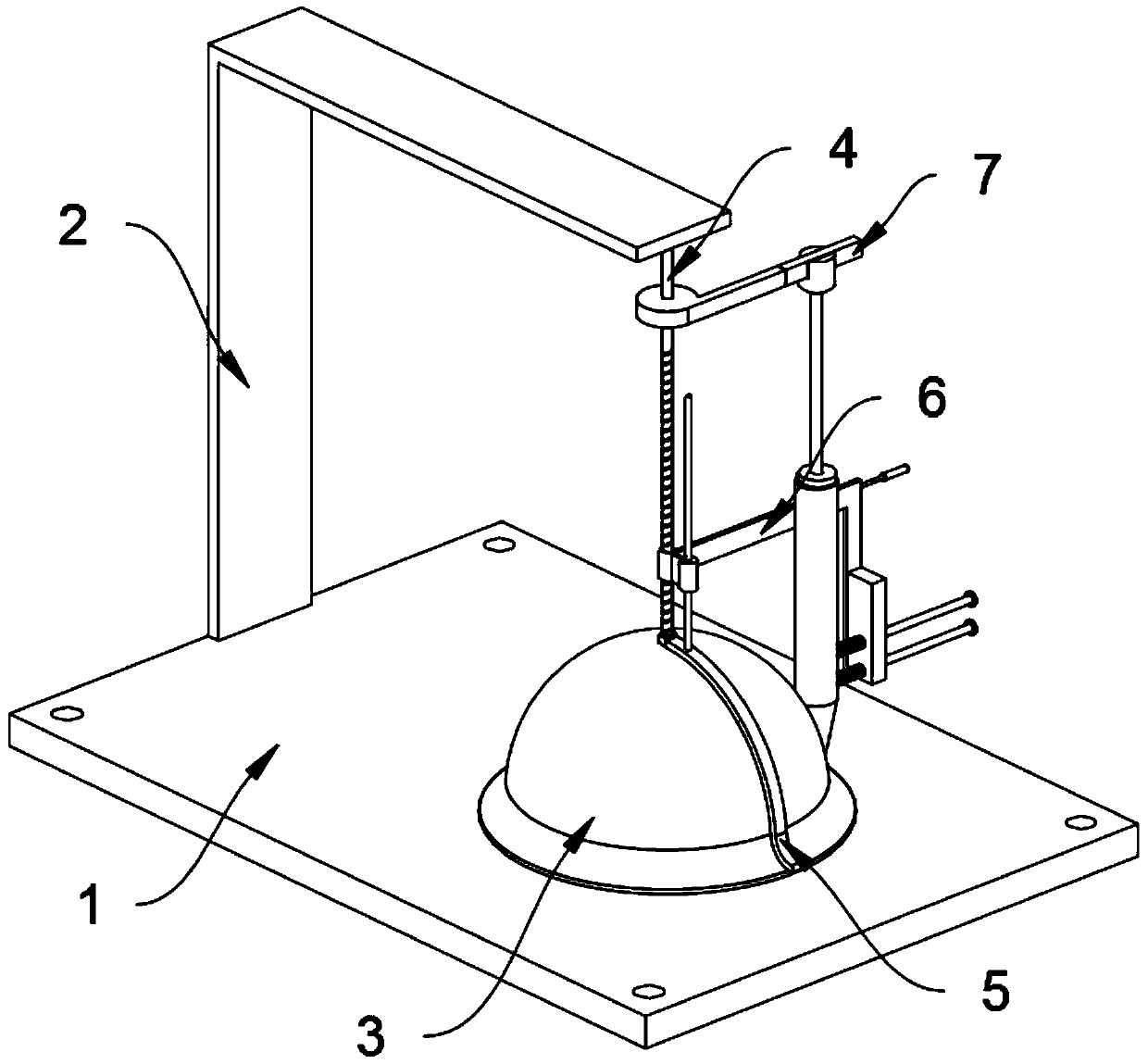

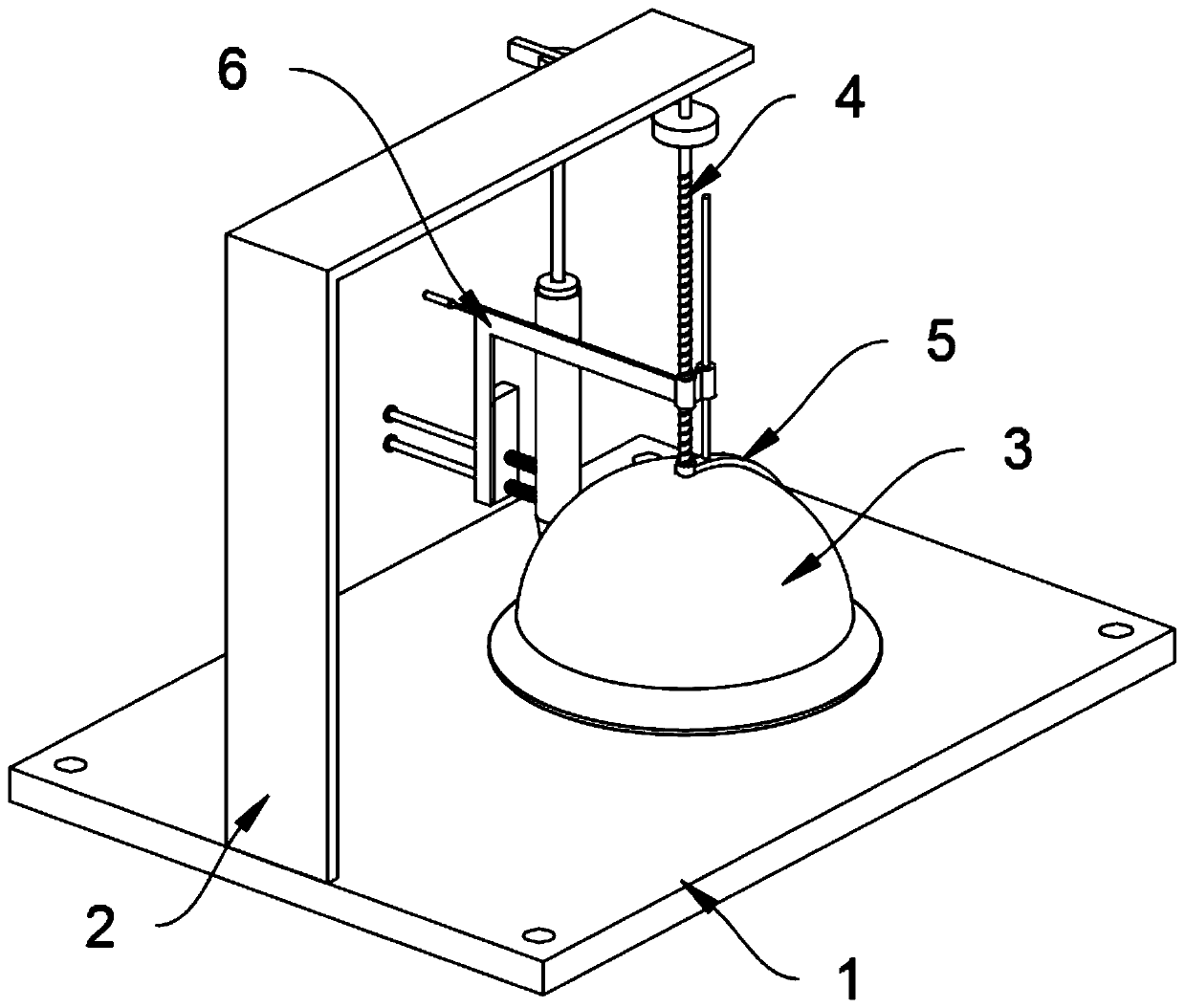

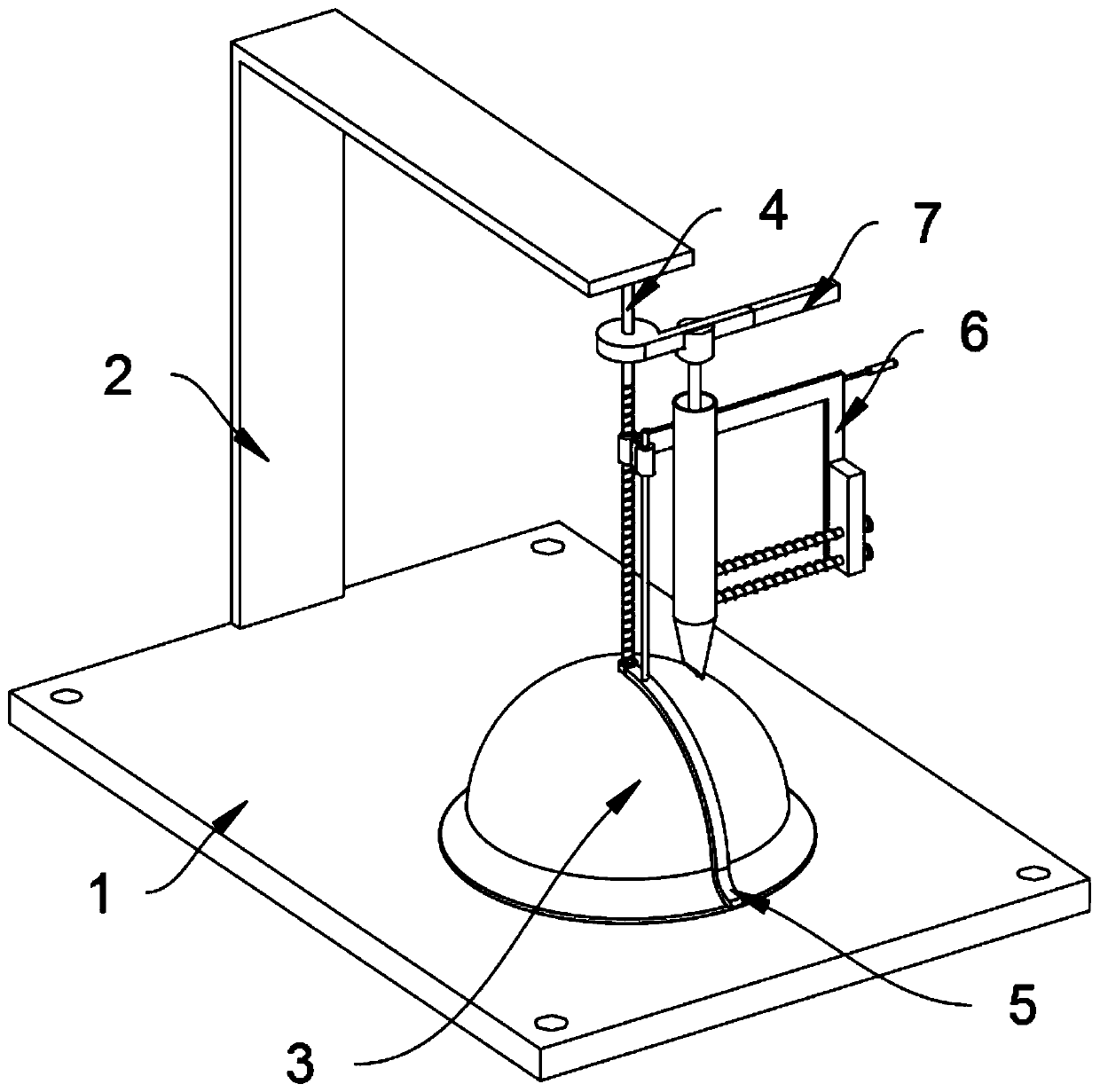

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a linkage claying device for making aluminum pot moulds, comprising a base 1; a mounting frame 2 is welded on the left side of the top of the base 1, a pot body 3 is placed on the right side of the top of the base 1, and a screw thread is installed on the top of the mounting frame 2 in a rotating manner The rod 4 is rotatably connected with a scraper structure 5 at the bottom end of the threaded rod 4, and the threaded rod 4 is provided with a mud feeding structure 6 and an extruding rod structure 7.

[0035] When in use, first pour the soil into the upper mud structure 6, then turn the upper mud structure 6, the extrusion rod structure 7 squeezes the mud in the upper mud structure 6, and apply the mud in the upper mud structure 6 on the pot body 3 , The scraper structure 5 can scrape the soil flat.

Embodiment 2

[0037] Reference as image 3 and Figure 4 The upper mud structure 6 includes a cylindrical nut 601, an upper mud bucket mounting frame 602, an upper mud bucket 603, a piston 604, a sliding limit rod 605, a spring 606 and a ball 607, and the threaded rod 4 is threadedly connected with a cylindrical nut 601 , the upper mud bucket mounting frame 602 is welded on the cylindrical nut 601, so in the process of use, the screw thread of the upper mud bucket mounting frame 602 can be realized when the upper mud bucket mounting frame 602 is rotated, so as to satisfy the spiral of the pot body 3. Ascending and smearing, the cylindrical nut 601 is welded to the sliding seat 503 through the connecting plate, then when the mud feeding structure 6 rotates, it can be linked to drive the scraper main body 501 to rotate, so that the rotation and scraping can be realized while the mud is being rotated, and the upper mud The sliding type in the mud bucket 603 is provided with a piston 604, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com