Multi-angle print paint spraying drawing device

A multi-angle, printmaking technology, applied in decorative arts, painting tools, etc., can solve the problems of stability, degree of freedom of adjustment, uniformity of spray paint, defects in adaptive adjustment, inconvenient work for staff, and inability to adjust spray paint. angle and other issues, to achieve high-efficiency and high-quality painting operations, comprehensive painting and painting operations, and the effect of improving the effect and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

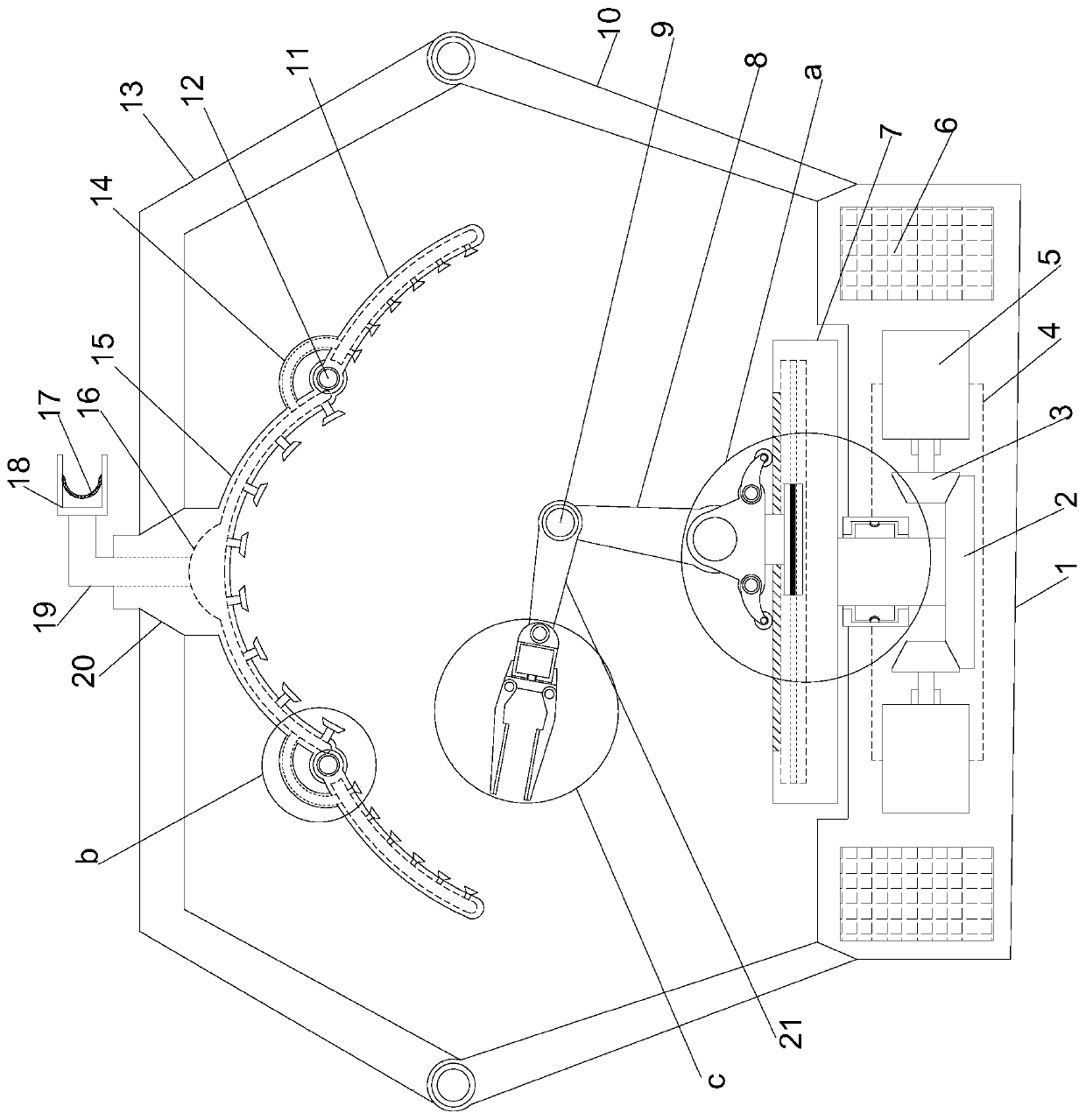

Embodiment 1

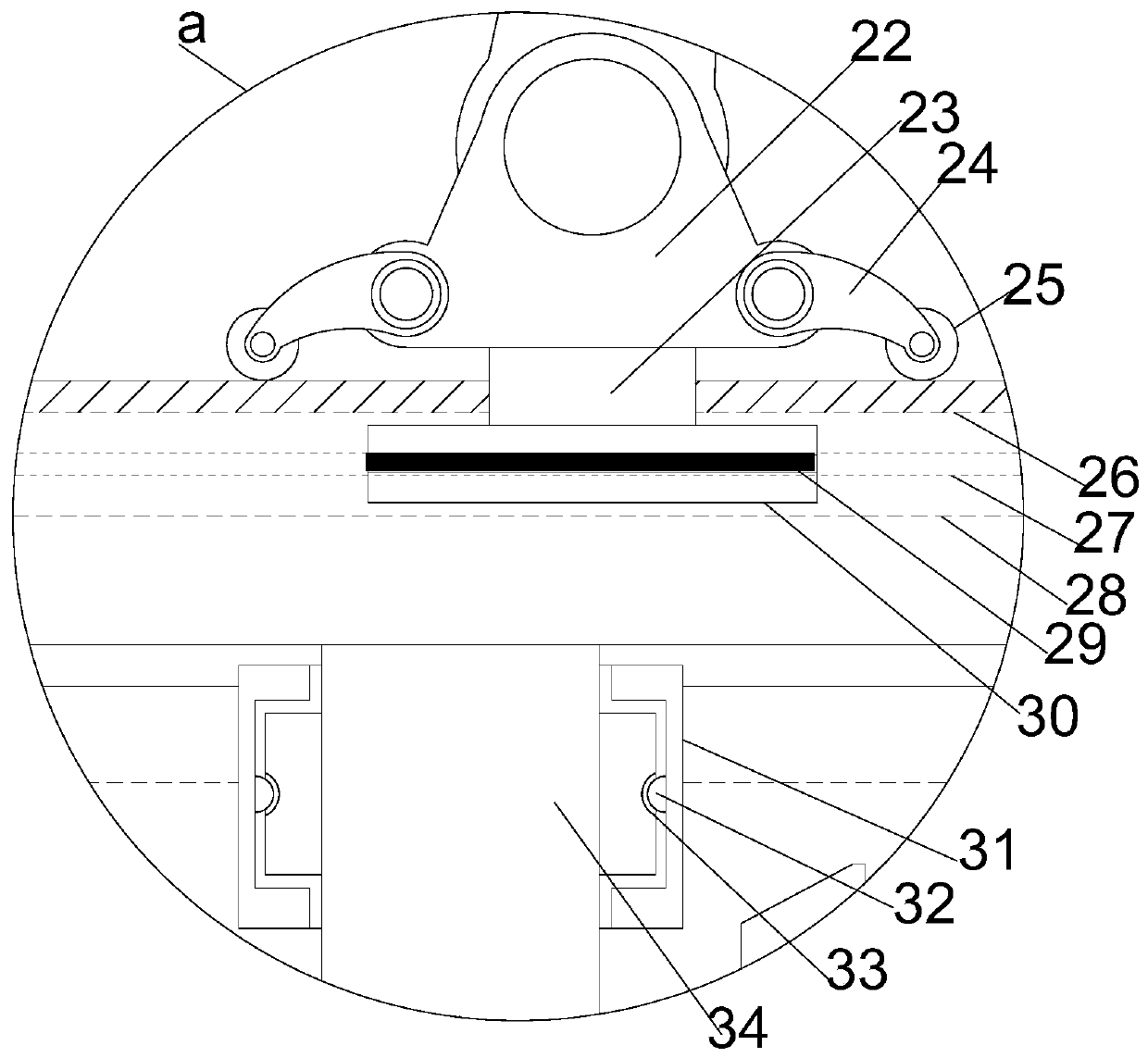

[0023] see Figure 1~5 , in the embodiment of the present invention, a kind of multi-angle print painting painting device, comprises the support installation board 1 that is arranged horizontally, and the support installation cover 13 is arranged directly above the support installation board 1, and both ends of the support installation cover 13 are all set downwards There is a rotating gate 10, and a transmission installation cavity 4 is horizontally arranged in the middle position of the support installation plate 1, and a storage battery 6 is embedded in the support installation plate 1 on both sides of the transmission installation cavity 4, and the top middle position of the support installation cover 13 is vertical. Directly provided with a guide installation cylinder 20, the guide installation cylinder 20 vertically runs through the support installation cover 13, the lower end of the guide installation cylinder 20 is provided with a spherical guide cover 15, and the lower...

Embodiment 2

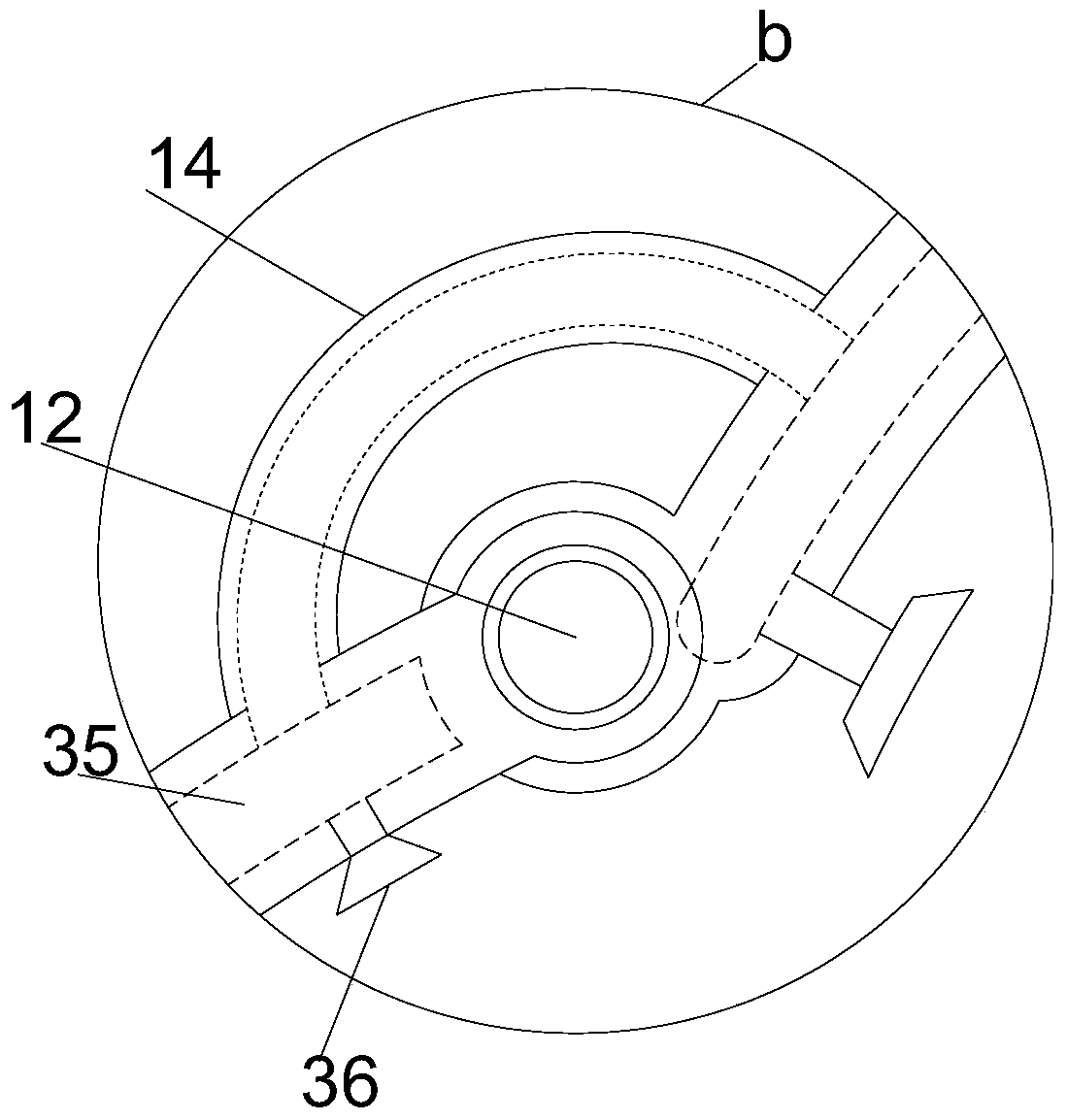

[0026]On the basis of Embodiment 1, during the movement of the mobile mounting frame 22 on the rotating mounting plate 7, due to the cooperation of the limit guide column 30 and the limit guide groove 28, and the cooperation of the mobile slider 23 and the mobile chute 26, the device has Good guiding and moving performance ensures the stability of the movement of the device, and the sliding conductive column 29 cooperates with the sliding conductive groove 27 during the movement to realize mobile coupling power supply, driven by the steering motor 37, so that the steering wheel 38 can rotate axially, further improving The freedom of movement of the prints improves the scope of application of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com