A continuous river sewage collection and cleaning system

A continuous type of dirt collection technology, which is applied in the cleaning of open water surfaces, construction, water conservancy projects, etc., can solve the problems of poor flow rate and increase the pressure of pressure-bearing equipment on both sides, so as to prevent deformation and improve load-bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

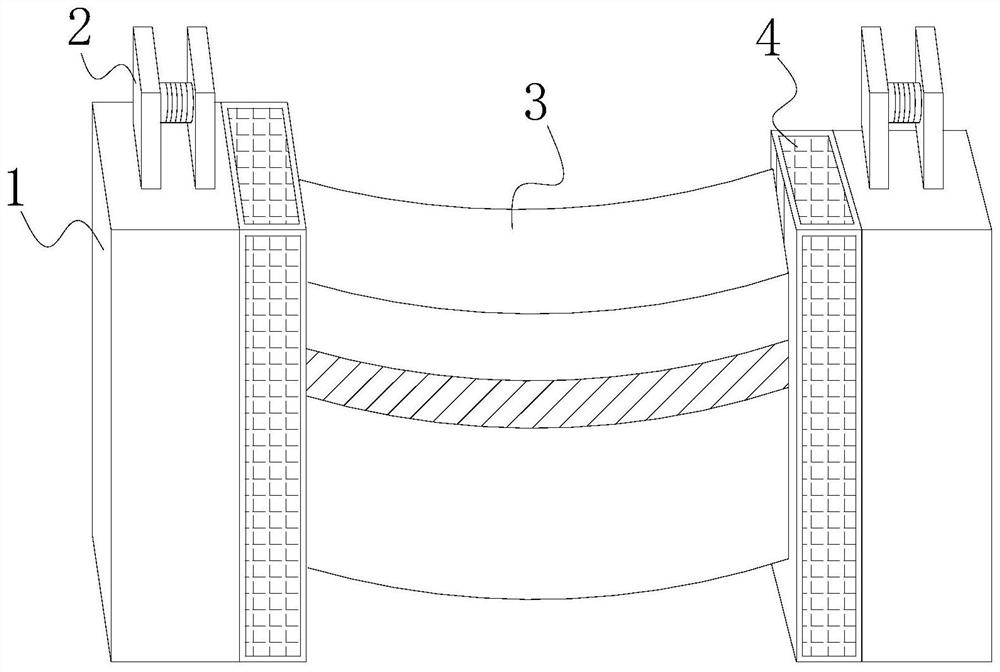

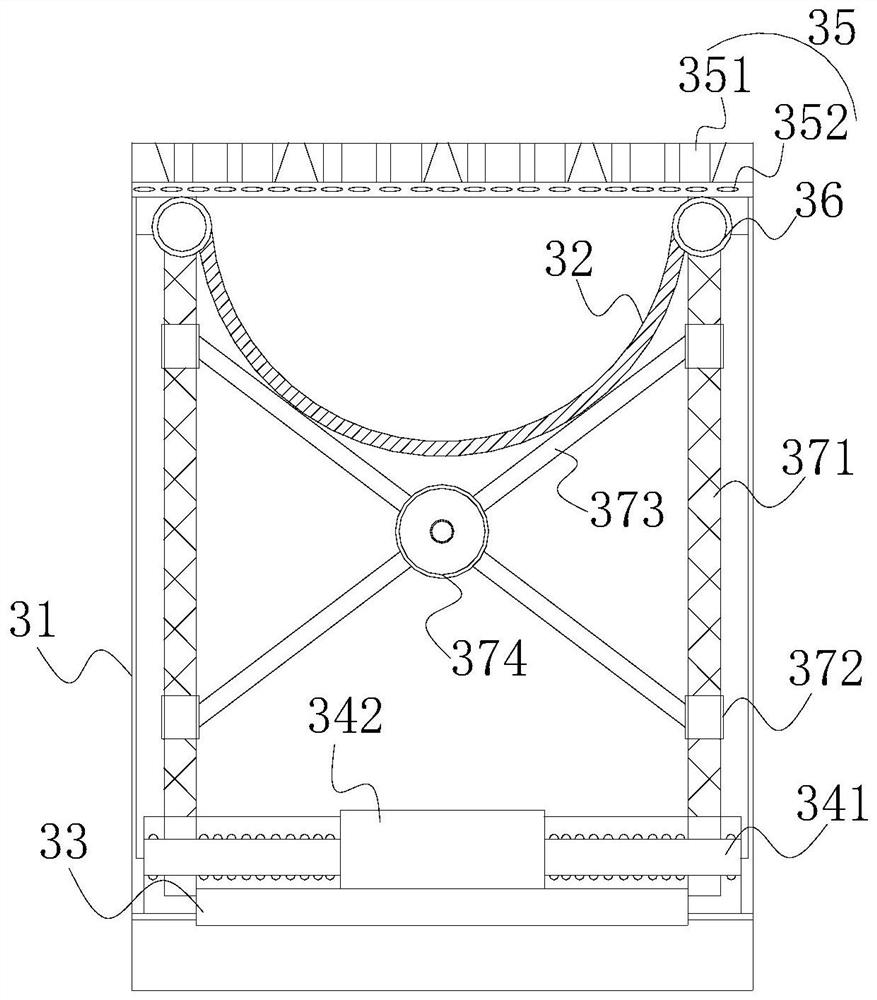

[0029] Such as Figure 1-Figure 3 As shown, the present invention provides a continuous riverway sewage collection and cleaning system, the structure of which includes a load-bearing platform 1, a hoist 2, a dirt-stopping plate 3, and a dirt-collecting tank 4. The hoist 2 of the plate 3, the connection between the dirt-blocking plate 3 and the dirt-collecting tank 4 is slidingly fitted, and the side matching position of the dirt-blocking plate 3 and the dirt-collecting tank 4 is provided with a chute. The dirt block 3 is a cavity type, and its top is not closed. The dirt block 3 is composed of a block body 31, a bearing liner 32, a support base 33, a lifting control center 34, an impact detection module 35, an installation port 36, An inner tank movable mechanism 37, the two ends of the bearing inner tank 32 are fixed inside the dirt block frame 31 through the installation opening 36, the impact detection module 35 is located at the upper end of the bearing inner tank 32, and ...

Embodiment 2

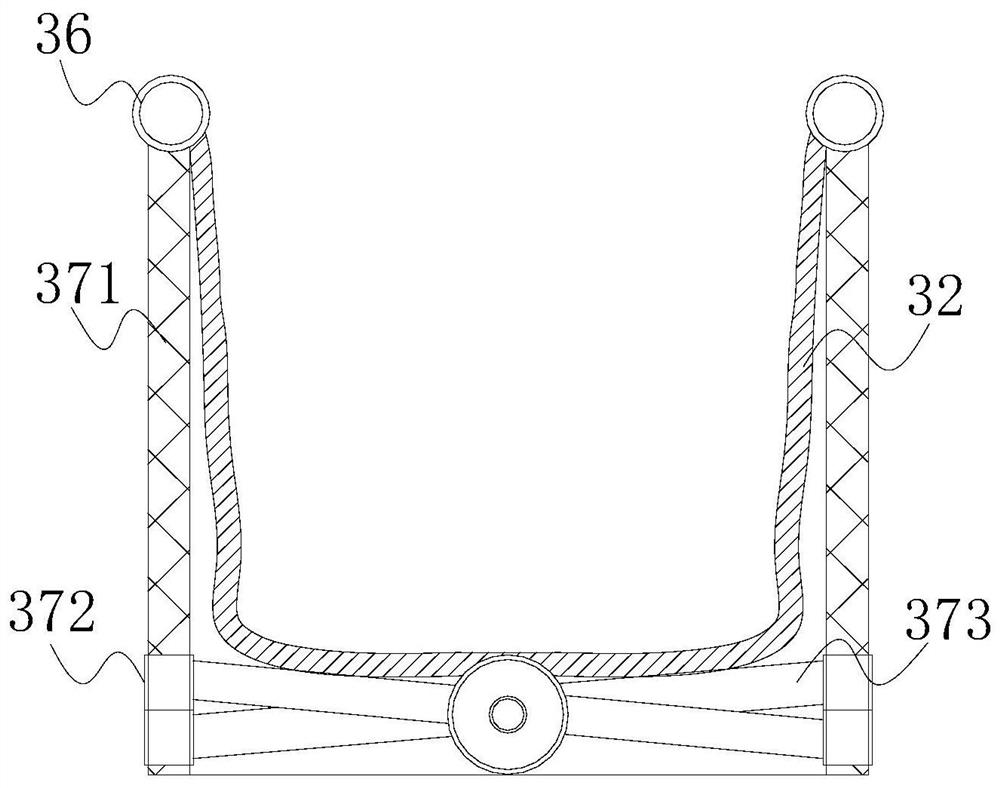

[0032] Such as Figure 4-Figure 5As shown, based on Embodiment 1 to achieve better water flow when the water level rises and falls and the trash catch plate can work normally, combined with the mutual cooperation of the following structural components, the shear rod 373 includes a telescopic sub-rod 731, a telescopic mother rod 732, a card slot 733, an interface 734, a block 735, and a counterweight assembly 736. The telescopic sub-rod 731 runs through the inside of the telescopic mother rod 732, and the two are telescopically matched in a horizontal straight line. There is an interface 734, on both sides of the interface 734 there are clamping blocks 735, on the inner surface wall of the telescopic female rod 732 there is a clamping groove 733 engaged with the clamping block 735, and the clamping grooves 733 are symmetrically distributed, symmetrical There are two on one side, and a counterweight assembly 736 is provided between the interfaces 734. The interface 734 is a cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com