A large-scale glass transportation device with good anti-rollover effect

A transportation device and anti-rollover technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as center of gravity elevation, rollover, etc., achieve simple structure, avoid glass tipping, and improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

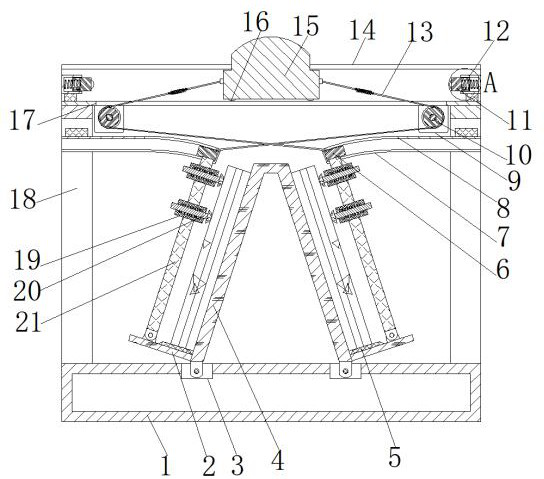

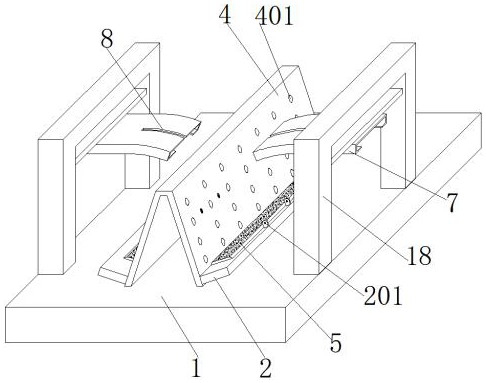

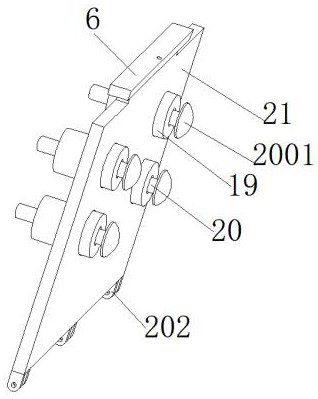

[0031] refer to Figure 1-5 , a large-scale glass transportation device with good anti-rollover effect, including a transport vehicle base 1, a support frame 4 with an opening downwards in an inverted V-shaped structure is provided in the middle of the upper surface of the transport vehicle base 1, and the support frames 4 are opposite to each other Both sides are fixed with pallets 2 perpendicular to the inclined planes near the bottom, and the upper surface of the transport vehicle base 1 is fixed with bow-shaped support frames 18 near the edges of both sides, and between the tops of the two support frames 18 The channel steel slide rail 14 that opening is upwards is fixed, slide block 15 is slidably connected in the chute of channel steel slide rail 14, and the groove bottom middle part of channel steel slide rail 14 has strip hole 17, and the channel steel slide rail 14 Both ends of the bottom near the bar-shaped hole 17 are provided with fixed pulleys 10, and the circumfe...

Embodiment 2

[0042] refer to Figure 6 , a large-scale glass transportation device with good anti-rollover effect. Compared with Embodiment 1, this embodiment also includes two sliding blocks 22 slidingly connected to the bottom of the transport vehicle base 1, and the two sliding blocks 22 rotate The same two-way screw 23 is connected, and the support frame 4 is hinged by the first support plate 401 and the second support plate, so that the inclination angle of the support plate can be adjusted by turning the two-way screw 23 during use, so that the glass body can be tilted at the most appropriate angle. Angle for transport.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com