Flying shooting control method and system

A control method and technology of a control system, applied to parts of TV systems, TVs, and color TVs, etc., can solve the problems of low shooting efficiency of workpieces and affecting process actions, so as to ensure process actions, ensure shooting quality, The effect of improving shooting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

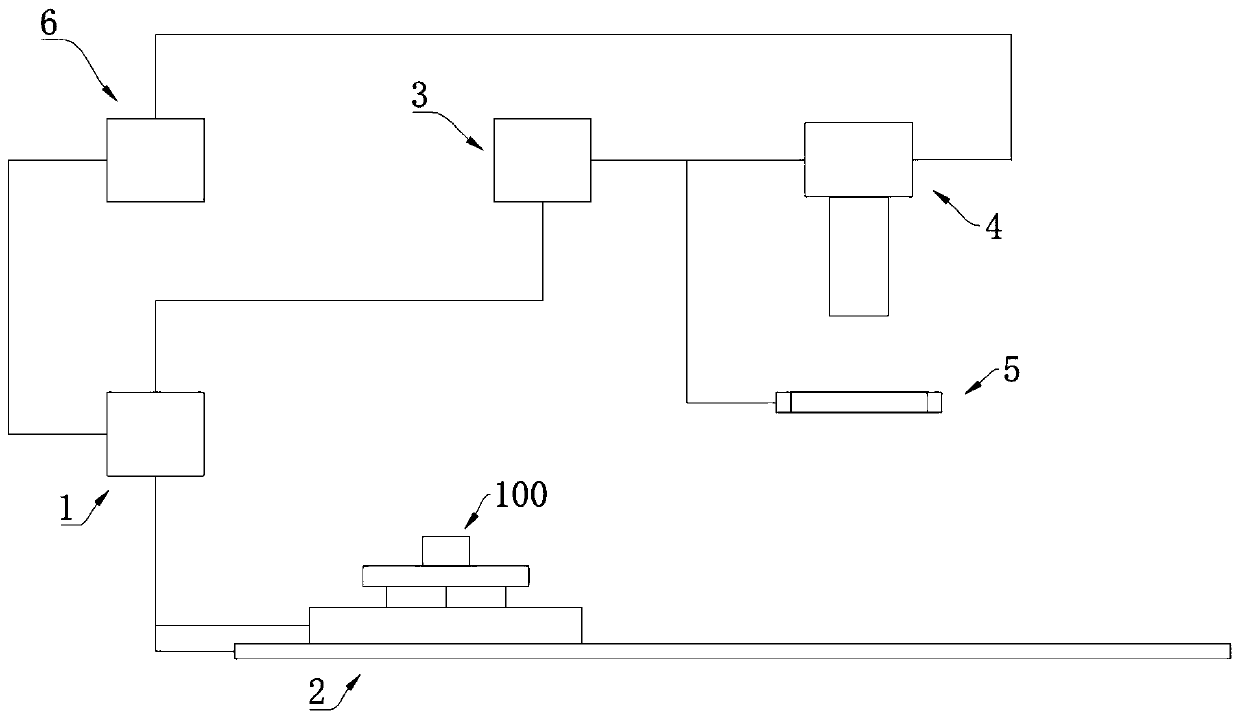

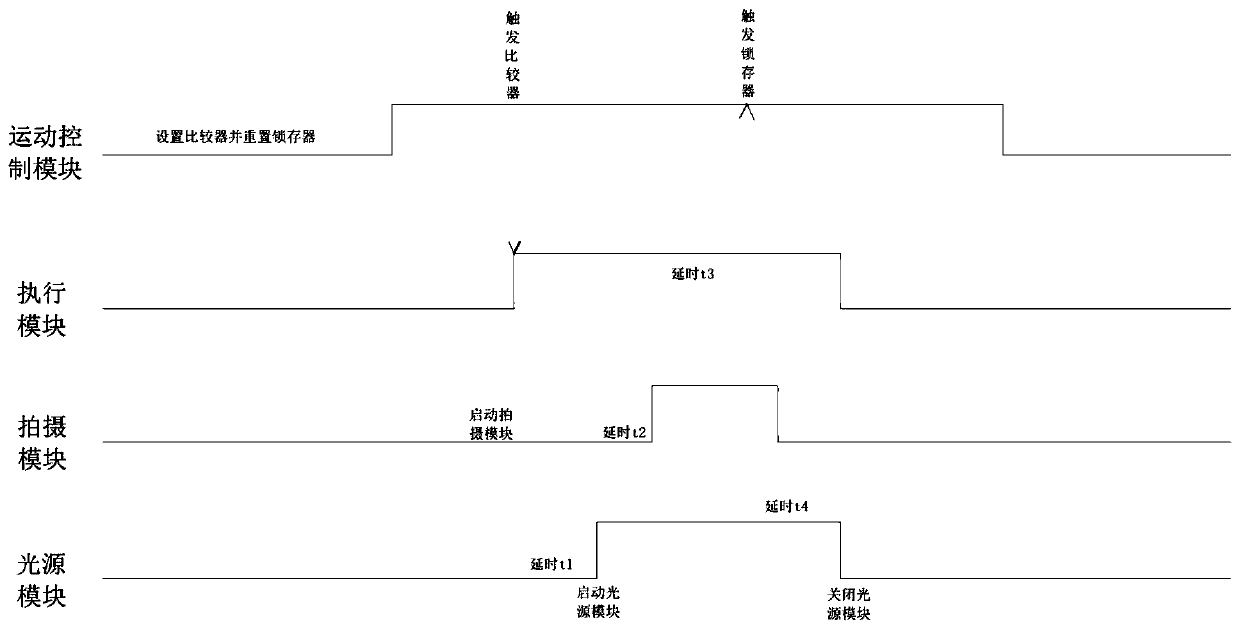

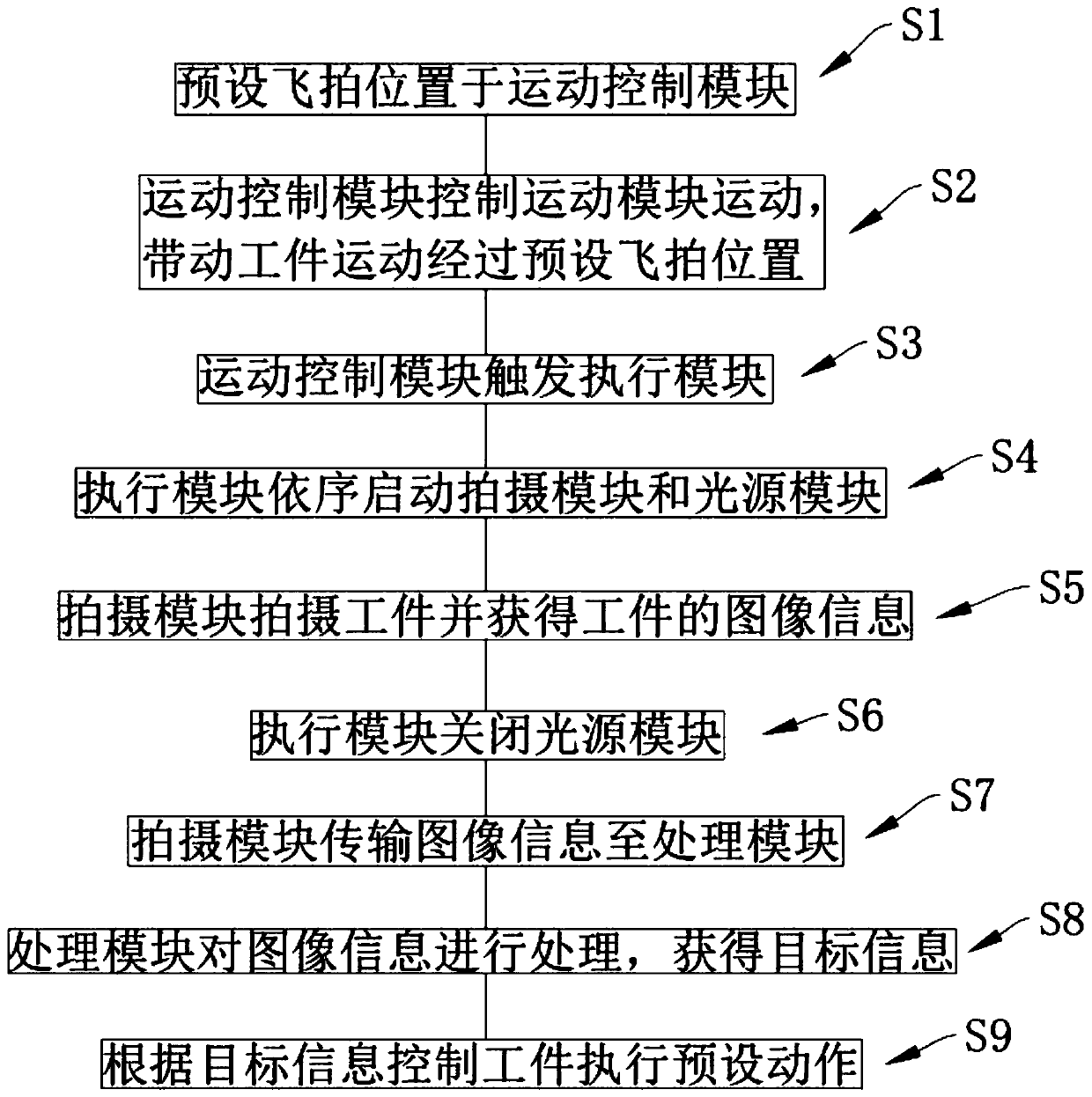

[0057] Continue to refer to Figure 1 to Figure 3 , image 3 It is a flow chart of the flying camera control method. The flying shooting control method in this embodiment is realized based on the flying shooting control system in the first embodiment, which specifically includes the following steps:

[0058] S1, the preset flying position is located in the motion control module 1.

[0059] S2, the motion control module 1 controls the motion of the motion module 2 to drive the workpiece 100 to move past the preset flying position.

[0060] S3, the motion control module 1 triggers the execution module 3 .

[0061] S4, the execution module 3 starts the camera module 4 and the light source module 5 in sequence.

[0062] S5, the photographing module 4 photographs the workpiece 100 and obtains image information of the workpiece 100 .

[0063] According to the preset flying position and the movement of the workpiece 100, the shooting and the light source required for shooting ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com