Method for monitoring, evaluating, and controlling cyclic chromatographic purification process

一种工艺、吸附器的技术,应用在用于监测、评估和控制循环色谱纯化工艺领域,能够解决阻碍实际应用等问题,达到稳健运行的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

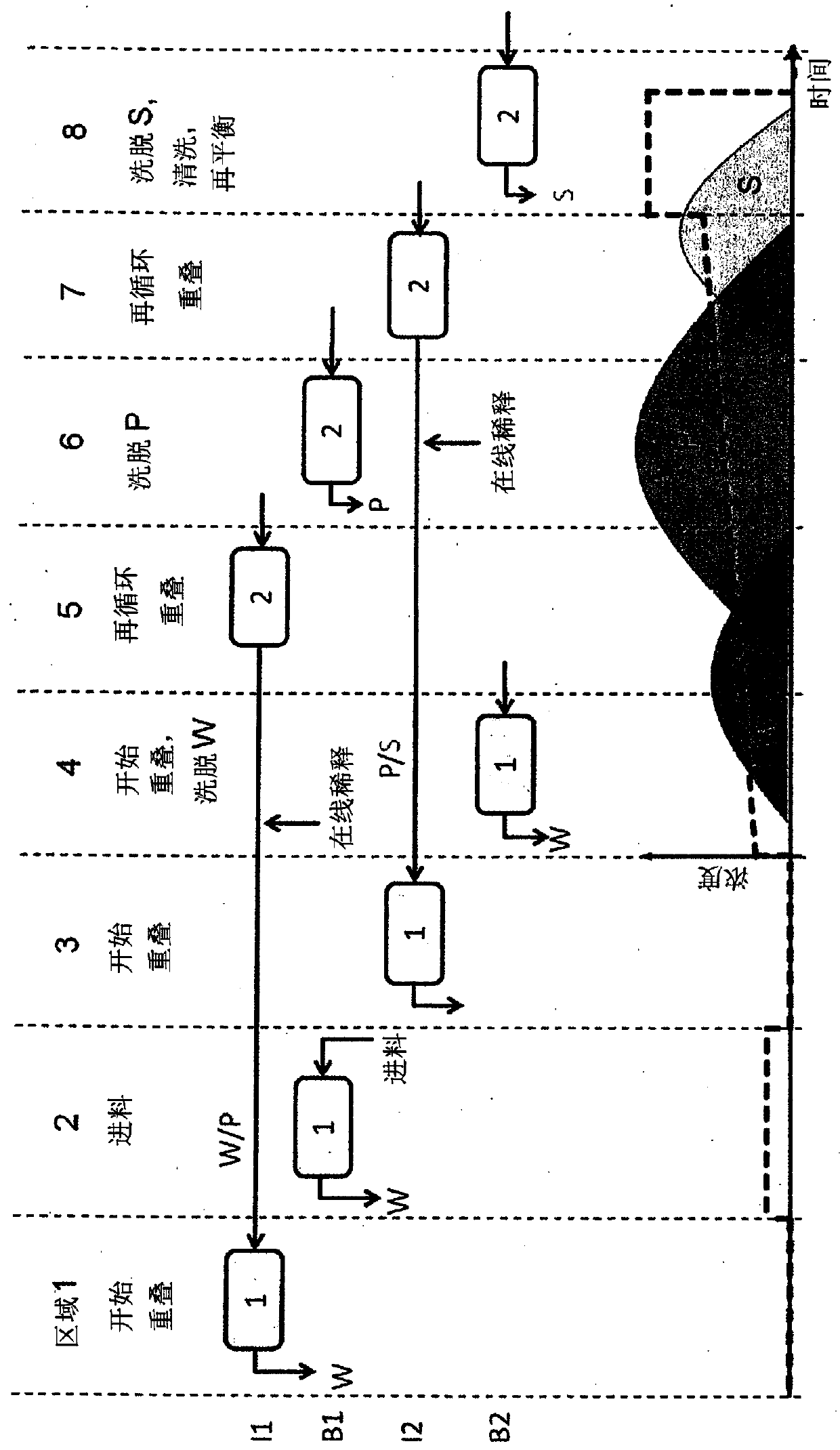

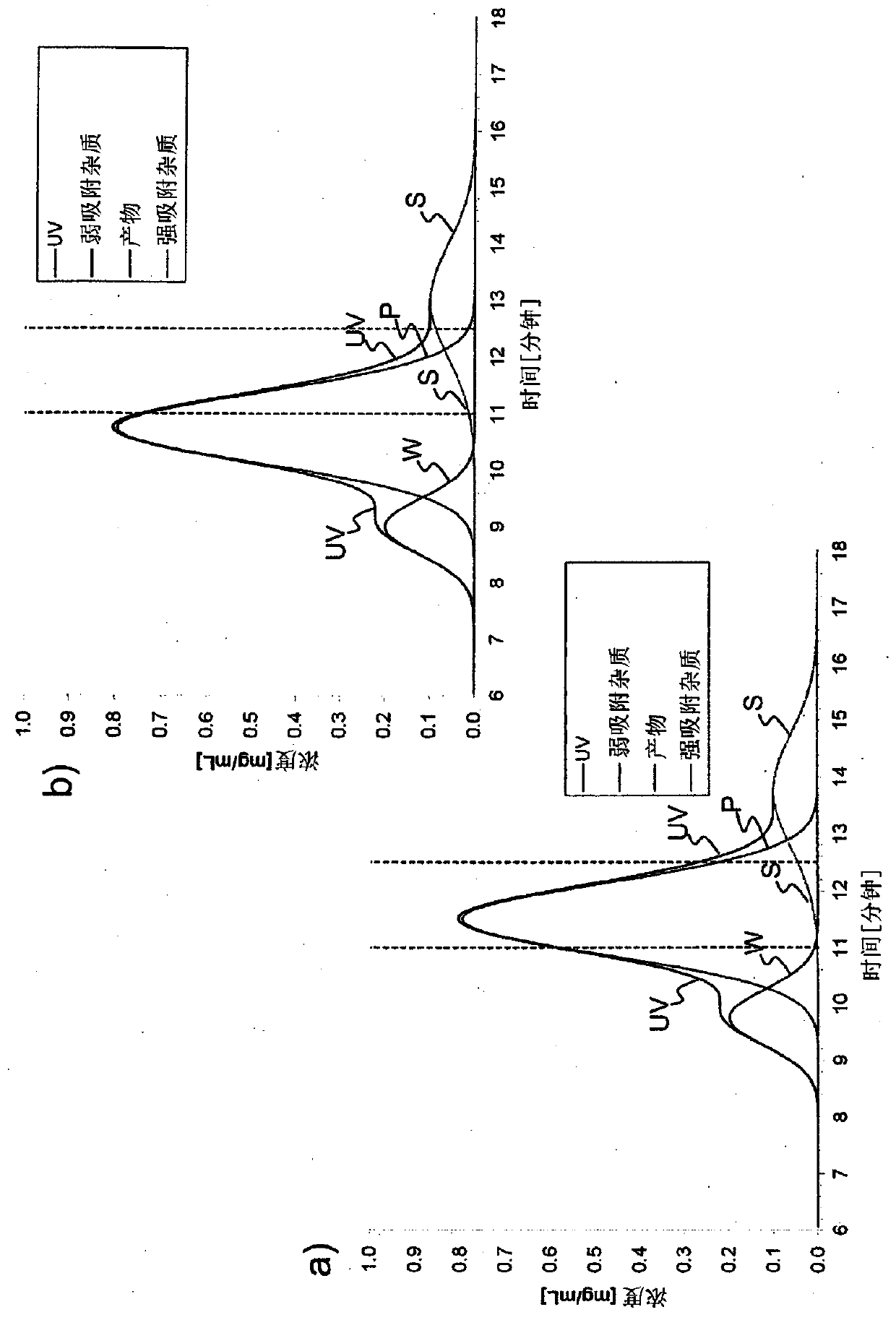

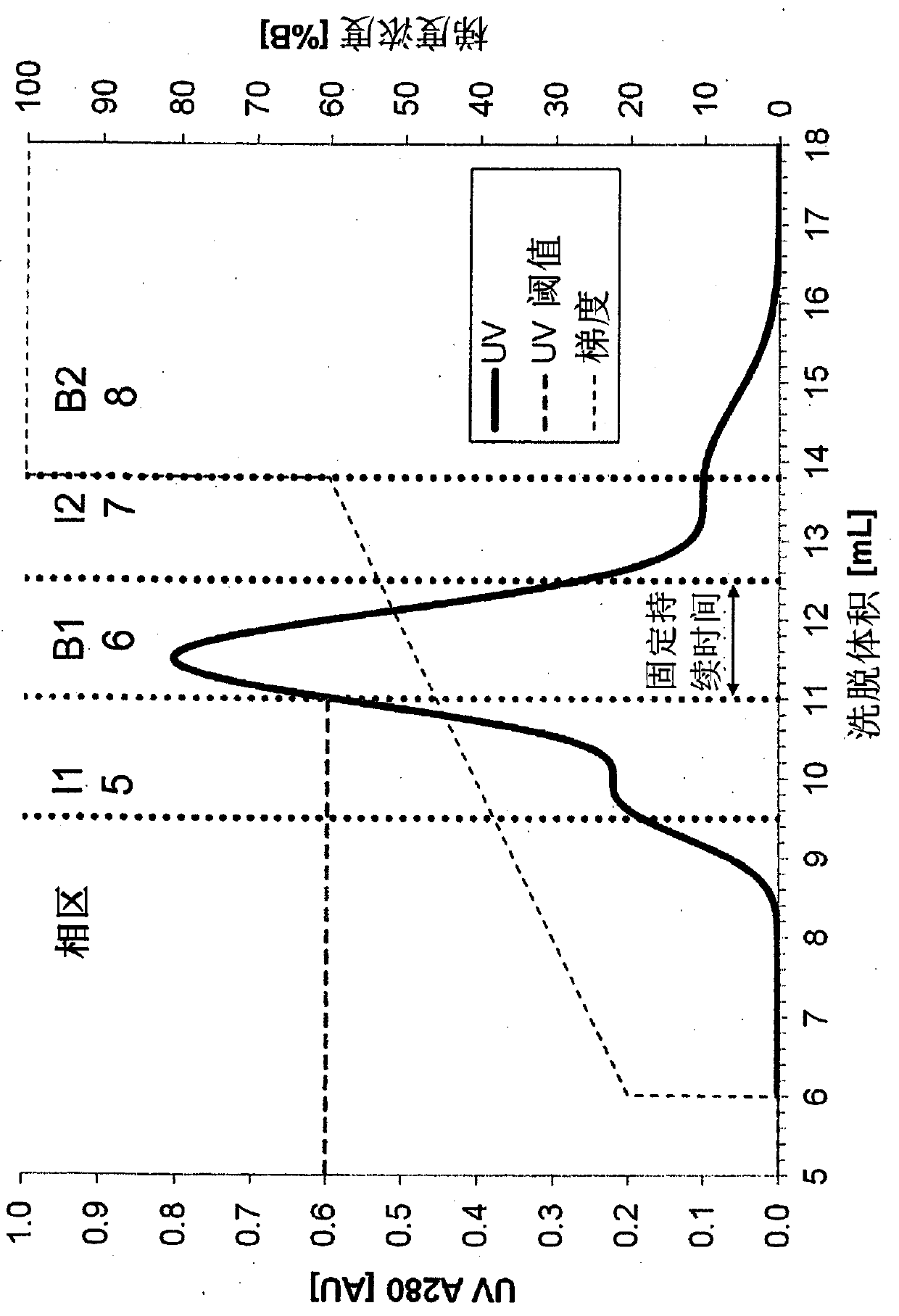

[0152] Example 1 [ Figure 9 ]:

[0153] The Contichrom system (ChromaCon AG) was operated using the control method (A). Two columns packed with different cation exchange stationary phases (Fractoprep SO3(M) and Gigacap SO3) were packed into a column with an internal diameter of 0.5 cm and a bed height of 10 cm. Two different resins were used to simulate columns with different column packing qualities. The system's operating software was programmed to continuously monitor the A280 UV signal at both column outlets and based on knowledge of the designed chromatogram set the UV threshold to start the product collection phase at 0.1 AU (=100 mAU). The duration of the product elution phase was fixed at 5.5 minutes.

[0154] The loading material was lysozyme solution, and the buffers used were buffer A: 25 mM phosphate, pH 6.0; buffer B: 25 mM phosphate, pH 6.0, 1 M NaCl; washing solution: 1 M NaOH. Figure 9 A shows the chromatogram of the cyclic operation of the MCSGP process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com