Device and method for measuring rolling line height of universal rolling mill

A technology of height measuring device and universal rolling mill, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of wear-resistant plate wear, rolling line height deviation, etc., and reduce the difficulty of head deviation adjustment , Improve production efficiency, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

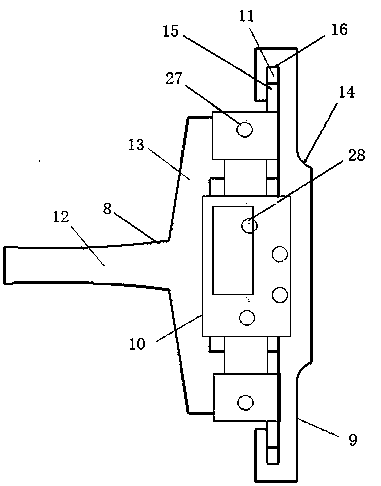

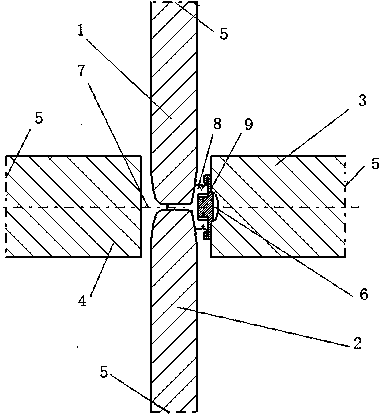

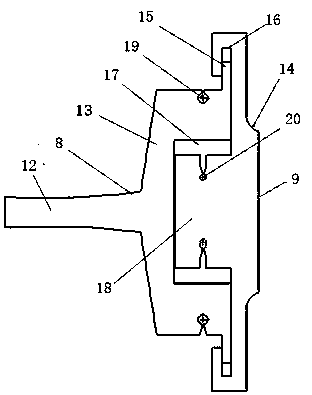

[0027] The present invention consists of a horizontal measuring board 8 , a vertical roller measuring board 9 , a digital display magnetic scale 10 and a calibration block 11 .

[0028] figure 1 , 2 Show, the plate face of horizontal measuring board 8 of the present invention and vertical roller measuring board 9 is in the same plane, horizontal measuring board 8 and vertical roller measuring board 9 are relatively connected, and digital display magnetic scale 10 is connected on horizontal measuring board 8 and vertical measuring board 9. On the surface of the roller measuring board 9, the calibration block 11 is embedded in the middle of the horizontal measuring board 8 and the vertical roller measuring board 9. The connected horizontal measuring board 8 and the vertical roller measuring board 9 are placed in the gap between the horizontal upper roller 1 , the underwater roller 2 and the head vertical roller 3 .

[0029] figure 1 , 2 , 3 shows that the horizontal measurin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com