A soil repair device

A soil remediation and crushing box technology, applied in the field of soil remediation, can solve the problems of uneven mixing effect of solid remediation agent and soil, short chemical remediation and remediation cycle, poor remediation effect, etc., so as to improve remediation efficiency and reduce remediation costs. , to improve the effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

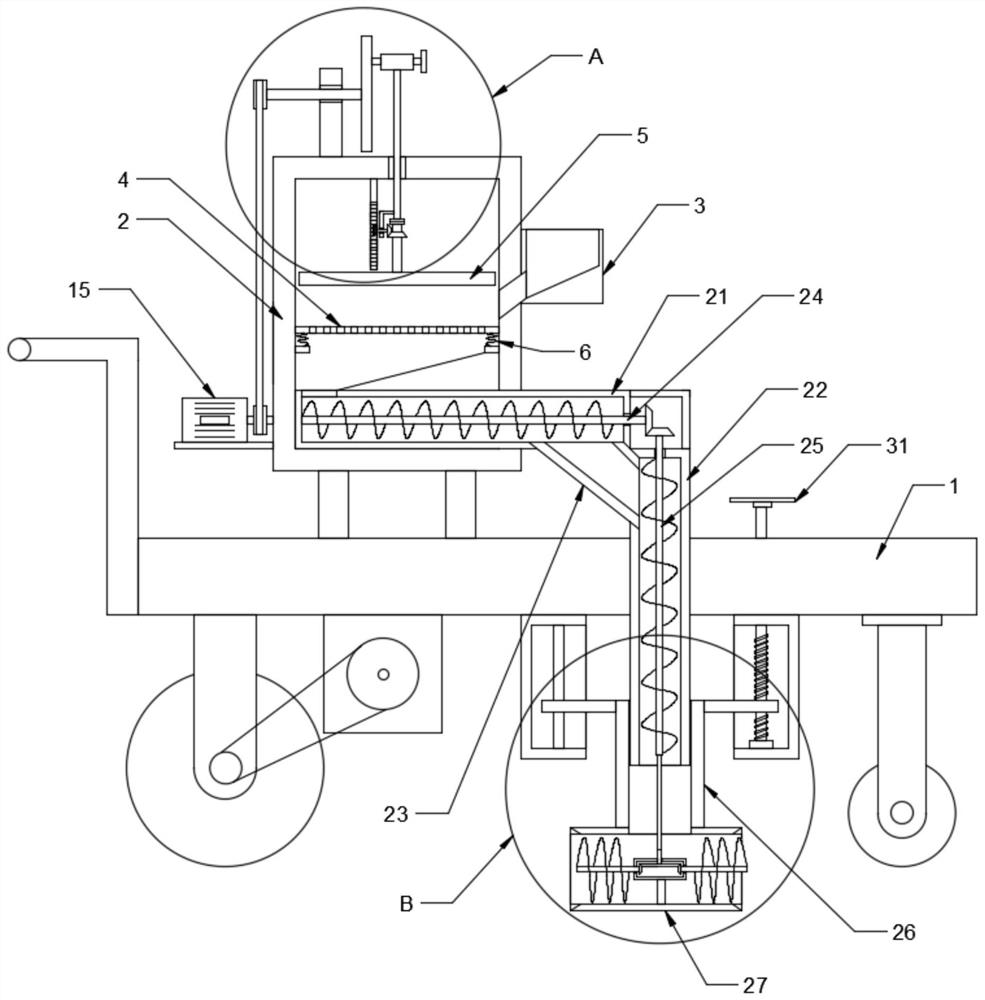

[0022] see figure 1 , in an embodiment of the present invention, a soil remediation device includes a device body; the device body includes a car body 1, a crushing mechanism, a conveying mechanism and a mixing mechanism; the crushing mechanism includes a crushing box 2, and the crushing box 2 and the car body 1 is fixedly connected, and one side of the crushing box 2 is connected with a feeding hopper 3, and the soil restoration powder is put into the crushing box 2 through the feeding hopper 3; Sliding connection, the lower end of the sieve plate 4 is fixedly connected to the inner wall of the crushing box 2 through the spring 6; the upper end of the sieve plate 4 is provided with a rolling plate 5, and the upper end of the rolling plate 5 is connected with an up and down rotation mechanism, which drives the rolling The disc 5 rotates up and down, and the rolling plate 5 that rotates up and down cooperates with the sieve plate 4 to crush and crush the solid material entering...

Embodiment 2

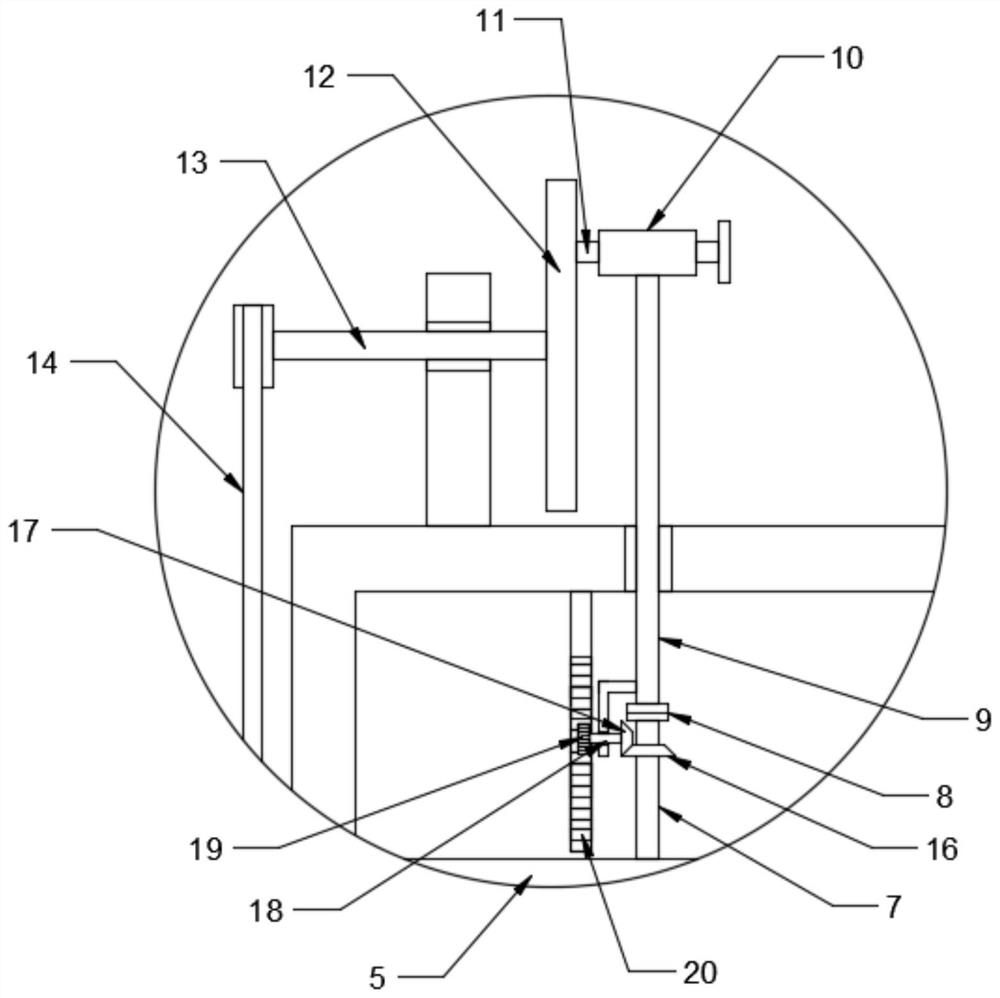

[0026] The difference between this embodiment and Embodiment 1 is that the up and down rotation mechanism includes a first rotating shaft 7 fixedly connected to the rolling plate 5, and the upper end of the first rotating shaft 7 is connected to a lifting rod 9 through a bearing seat 8 in rotation, and the lifting rod 9 Extending to the top of the crushing box 2, the upper end of the lifting rod 9 is fixedly connected with a rectangular frame 10, the rectangular frame 10 is nested with an eccentric rod 11, the eccentric rod 11 is fixedly connected with a turntable 12, and the turntable 12 is fixedly connected with a second rotating shaft 13, the second The rotating shaft 13 is connected with the output shaft of the driving motor 15 through the transmission belt 14, and the output shaft of the driving motor 15 drives the turntable 12 to rotate through the transmission belt 14 and the second rotating shaft 13. To reciprocate up and down, the rectangular frame 10 drives the rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com