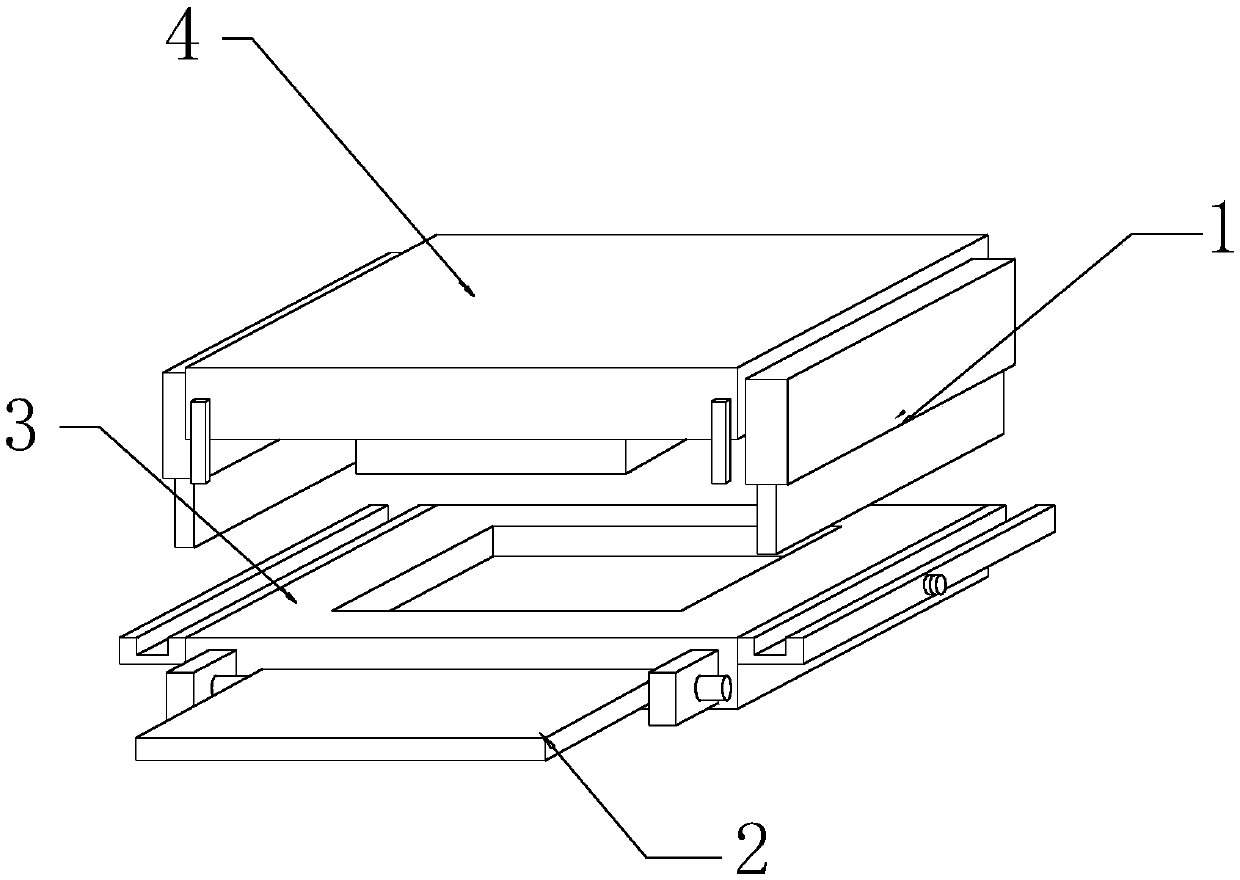

Stamping die protective device

A technology of protective device and stamping die, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as low safety factor, hidden safety hazards, and waste splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

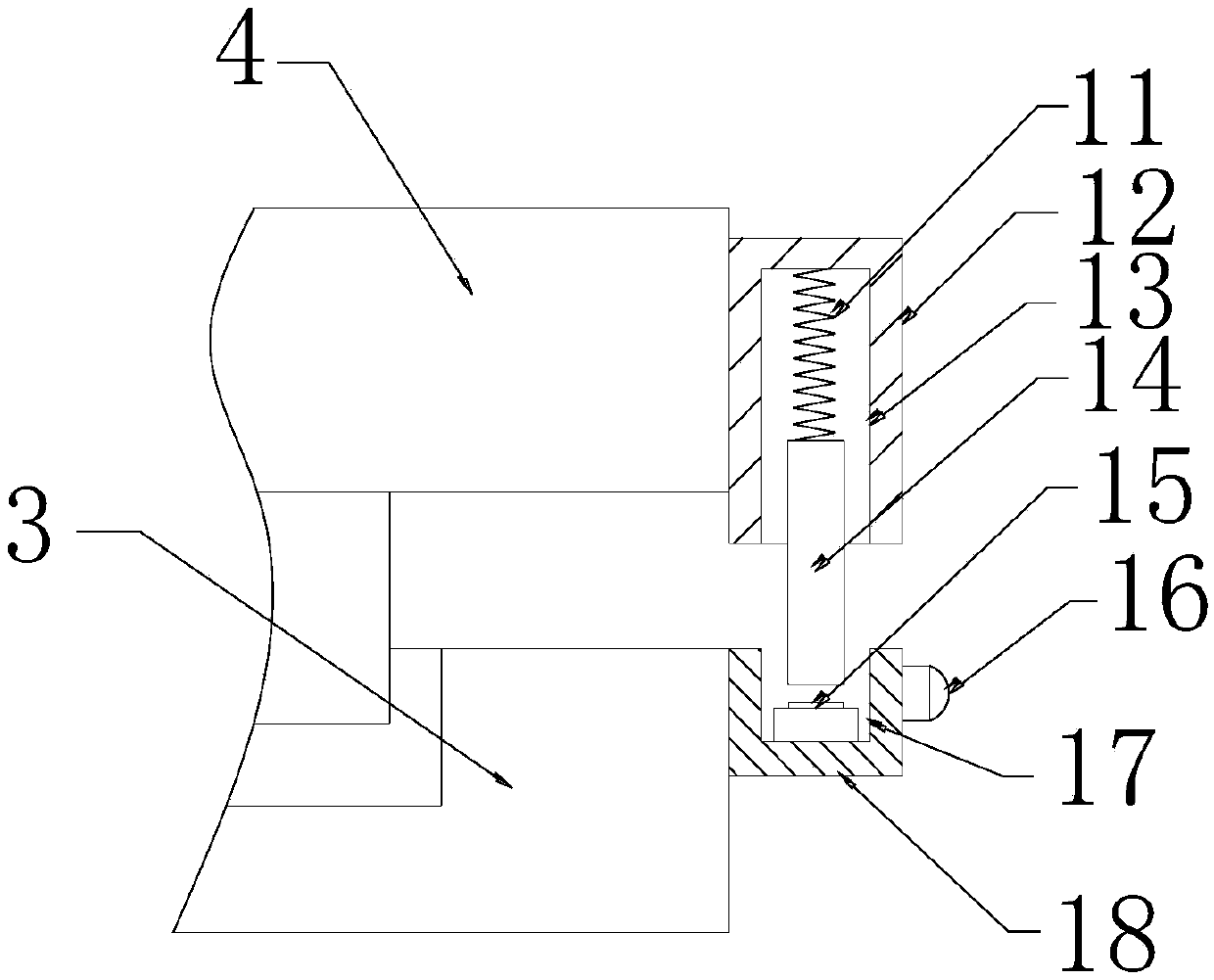

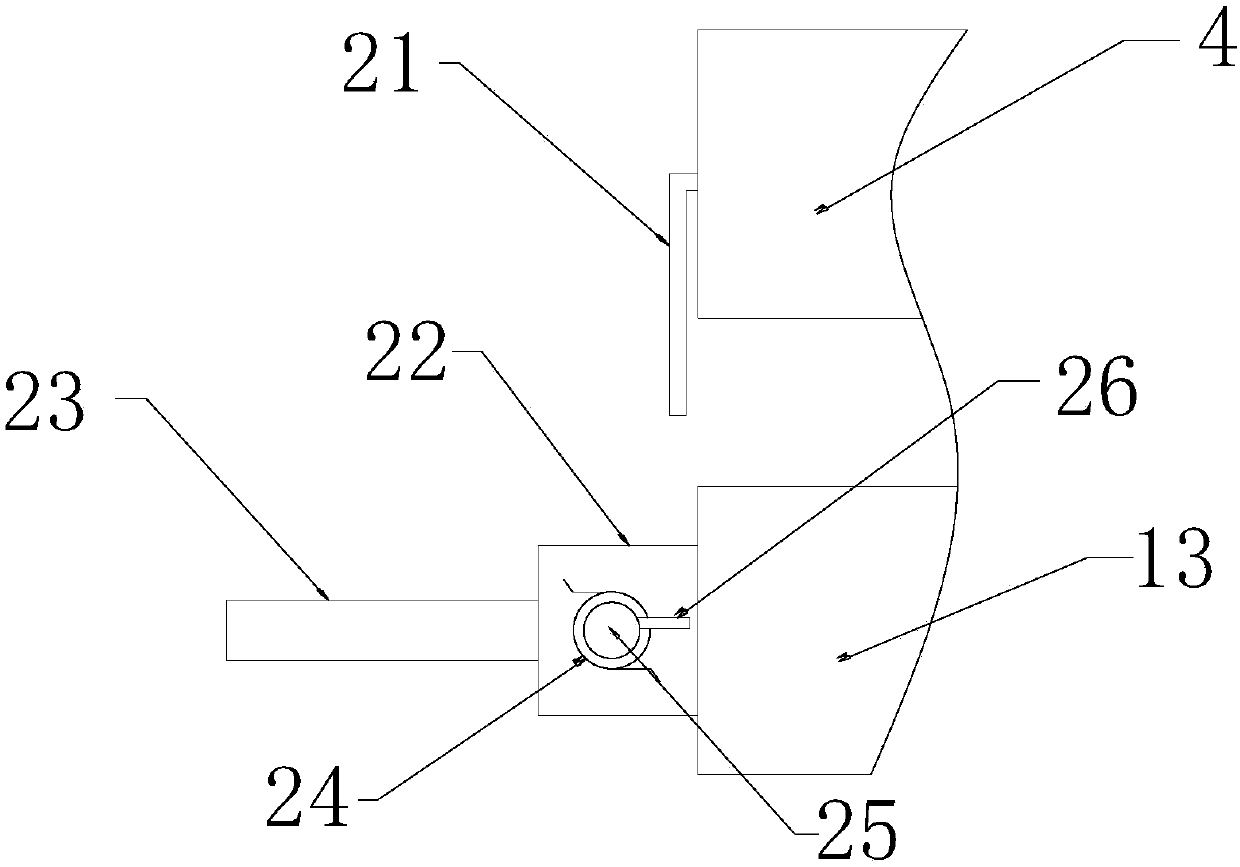

[0021] Specific implementation: when in use, the press drives the upper mold 4 to move downward, and the upper mold 4 moves downward to drive the upper bearing plate 12 and the lower protective plate 14 to move downward. After the lower protective plate 14 moves into the card slot 17, the lower Protective plate 14 collides travel switch 15, and travel switch 15 then connects the circuit of warning lamp 16, and then warning lamp 16 lights up, and lower die 3 continues to move downwards, and then upper carrying plate 12 moves downwards, and then lower protective board 14 squeezes Press the return spring 11 to make the return spring 11 elastically deform, and make the lower protective plate 14 always fixed in the card slot 17. After the operator observes that the warning light 16 lights up, the operator is reminded to stay away from the work area, thereby realizing the use of the device. The automatic protection and early warning function ensures the personal safety of the operato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com