Circled lining sewing mould and method

A sewing and mold technology, which is applied in the field of loop lining sewing, can solve the problems of low work efficiency, difficult operation, and unguaranteed quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Loop lining sewing mold

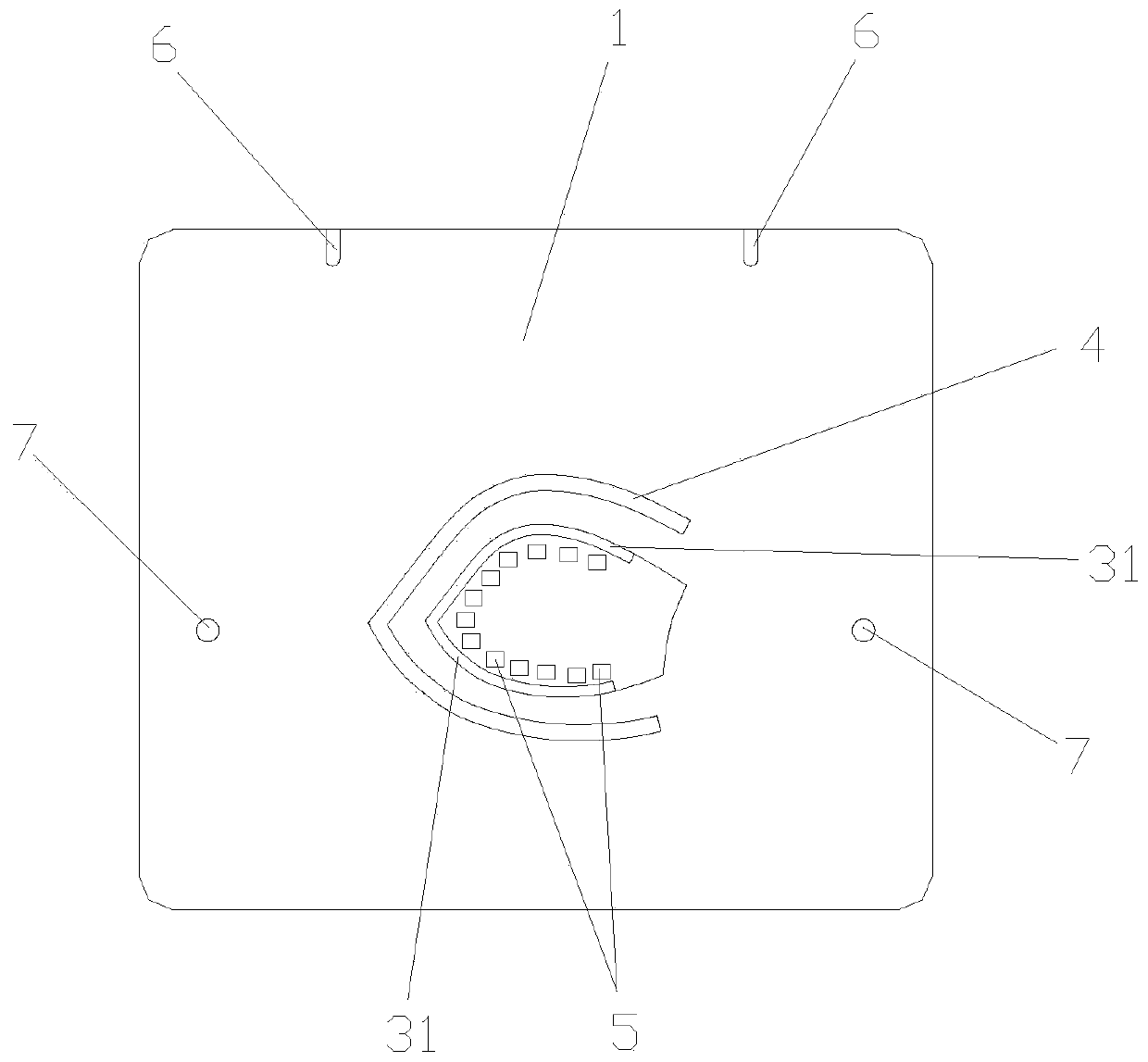

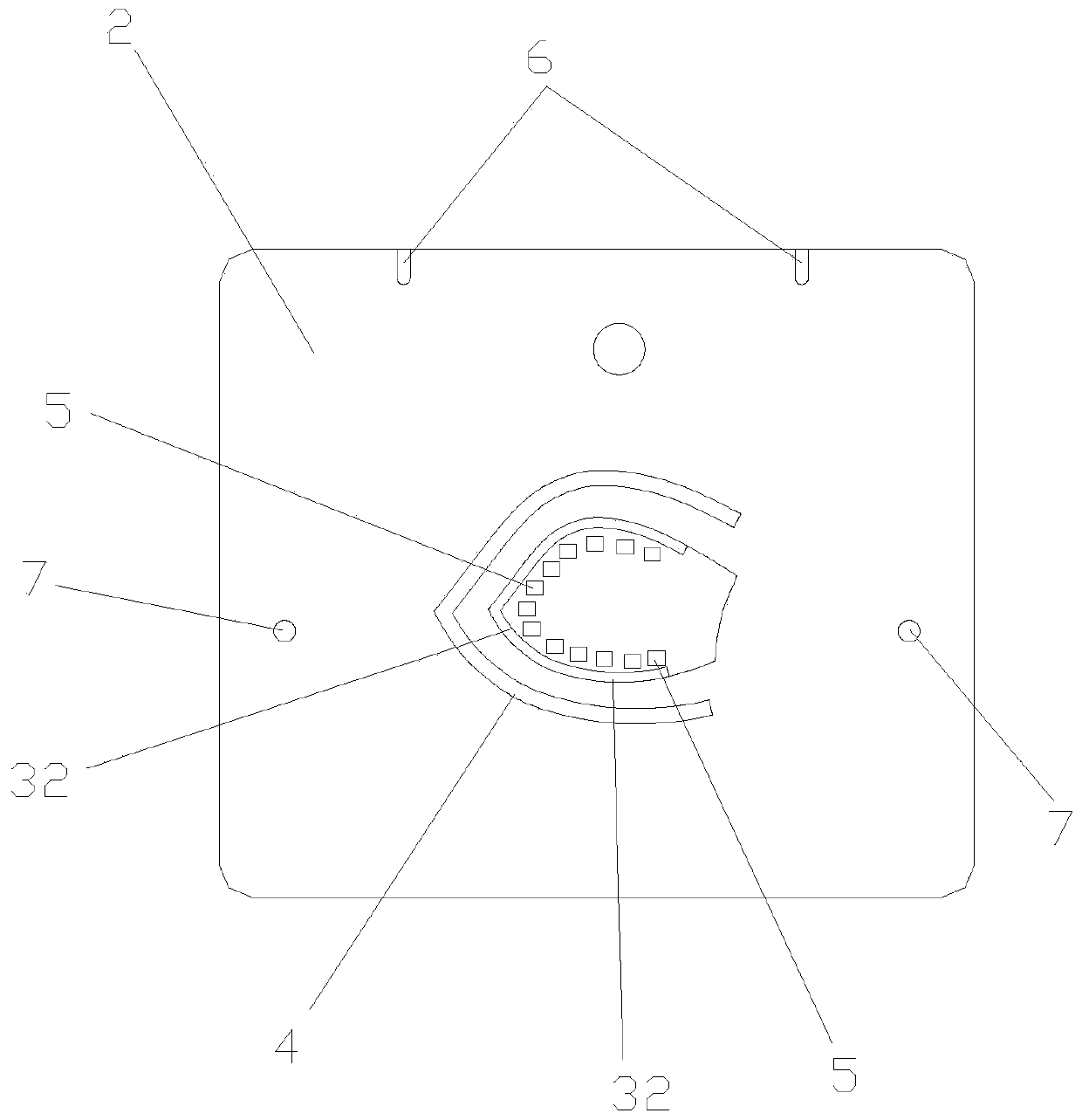

[0030] see Figure 1-2 , the loop lining sewing mold in this embodiment includes a first template 1 and a second template 2 that cooperate with each other, and the first template 1 and the second template 2 are correspondingly provided with sewing grooves that run through their respective thicknesses. The limit line is set, and the outside of the sewing groove is also provided with a blocking strip 4 for blocking the outer edge of the lining sheet, and the inside of the sewing groove is also provided with a pressing block 5 for pressing the lining sheet, and the pressing block 5 and the blocking strip 4 are respectively Located on the inside and outside of the sewing slot. Both the first template 1 and the second template 2 are plate-shaped transparent materials such as PET, PBT boards, etc., so as to facilitate observation of sewing conditions.

[0031] Sewing groove comprises the first sewing groove 31 that runs through the fir...

Embodiment 2

[0039] Embodiment 2 sewing method of loop lining

[0040] The loop lining sewing method in the present embodiment is based on the loop lining sewing mold in embodiment 1, specifically comprises the following steps:

[0041] 1) design

[0042] Design the style of the lining, and preset the sewing path and the width of the sewing line.

[0043] 2) material preparation

[0044] Prepare the lining piece according to the lining style designed in step 1).

[0045] 3) Unloading

[0046] Correspondingly place the lining pieces in the ring lining sewing mold, the outer edges of the lining pieces correspond to the blocking strips 4, and then rotate and fit the first template 1 and the second template 2 so that the lining pieces are located between the first template 1 and the second template 2. Between the second templates 2, the pressing block 5 presses the lining sheet.

[0047] 4) Sewing

[0048] Place the circle lining sewing mold with the lining sheet on the sewing equipment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com