sewing device

A sewing and sewing machine technology, which is applied in the field of sewing devices, can solve problems such as large alignment errors of clothing components, high concentration of operators, and unstable clothing quality, and achieve the effects of fast sewing speed, low labor cost, and improved practical flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

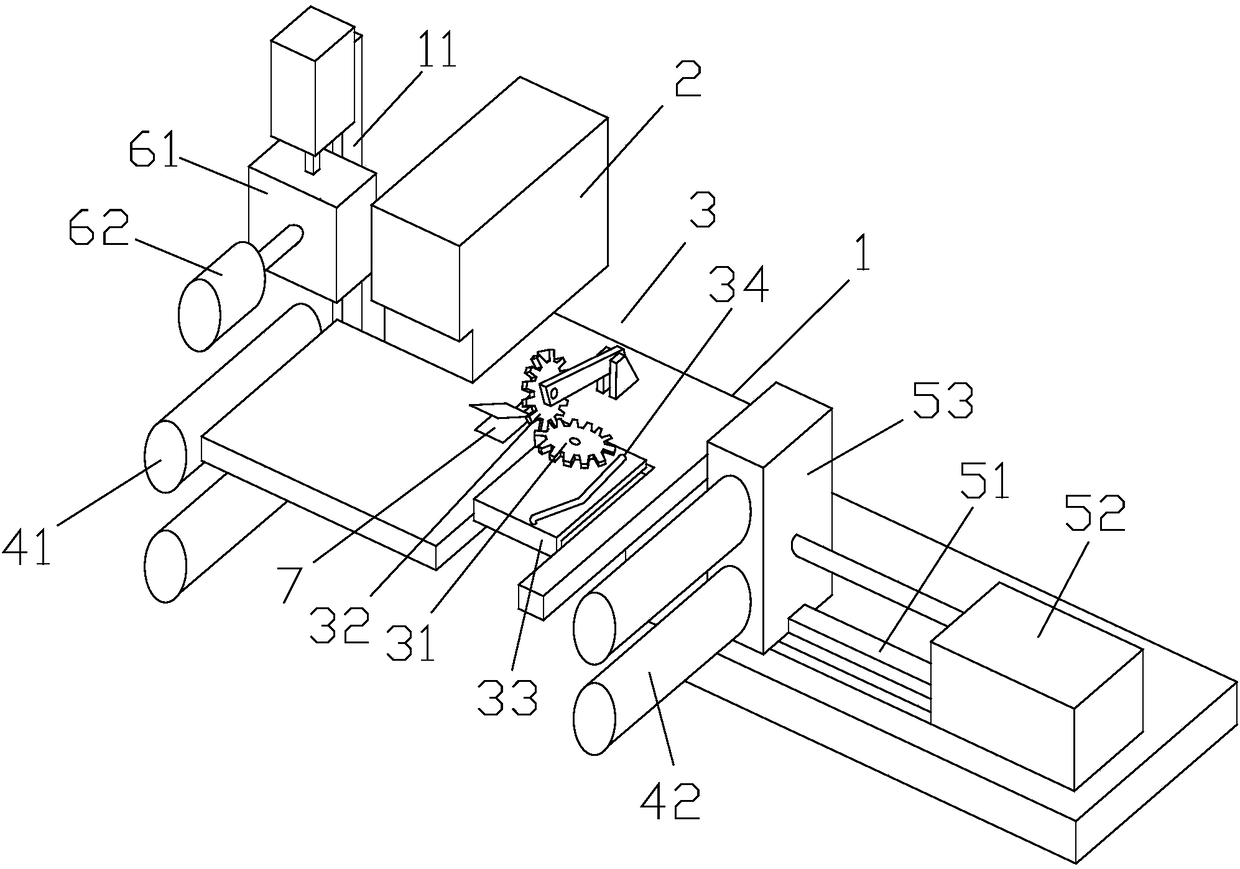

[0034] When sewing two pieces of clothing parts in planar form, the two clothing parts are first aligned and stacked, and one end is aligned and sent to the sewing machine. material. If one of the clothing parts is fragile and should not be twisted by the engaged gear, then this clothing part is placed on the lower floor, and it enters into the horizontal support 33 by pushing and pulling the horizontal support 33, guided by the guide groove.

[0035] The vertical gear 32 then falls, engages with the horizontal gear 31 and clamps the corresponding garment part.

[0036] Then sewing machine 2 works, and the feeding structure of sewing machine 2 itself pulls the clothing parts laterally, and the clothing parts are gradually fed in and stitched. Simultaneously vertical gear 32 rotates, because vertical gear 32 is perpendicular to the direction that clothing part moves, the two gears that rotate and engage longitudinally promote clothing part, make it move to the side near sewing...

Embodiment 2

[0039] When sewing two ring-shaped garment parts, the sewing device needs to be provided with backup rollers. First, put two garment parts on the back-up roller in a layered manner, the front end of the clothing part is pasted on the main roller 41, the middle part is located in the sewing machine 2, the positioning frame 7 and the horizontal gear 31 successively, and the rear part is pasted on the auxiliary roller 42 .

[0040] Then the push-pull device 52 drives the sliding seat 53 to make the auxiliary roller 42 away from the main roller 41, so that the garment parts are tensioned, and the feeding of the garment parts is completed. If one of the clothing parts is fragile and should not be twisted by the meshed gear, then this clothing part is placed on the lower floor, and it enters into the horizontal support 33 by pushing and pulling the horizontal support 33, guided by the guide groove.

[0041] The vertical gear 32 then falls, engages with the horizontal gear 31 and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com