Maintenance method for electrical connector of tramcar

A technology for electrical connectors and trams, used in the measurement of resistance/reactance/impedance, instruments, scientific instruments, etc., can solve the problems of inaccurate test results, increased maintenance costs, and differences in vehicle quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

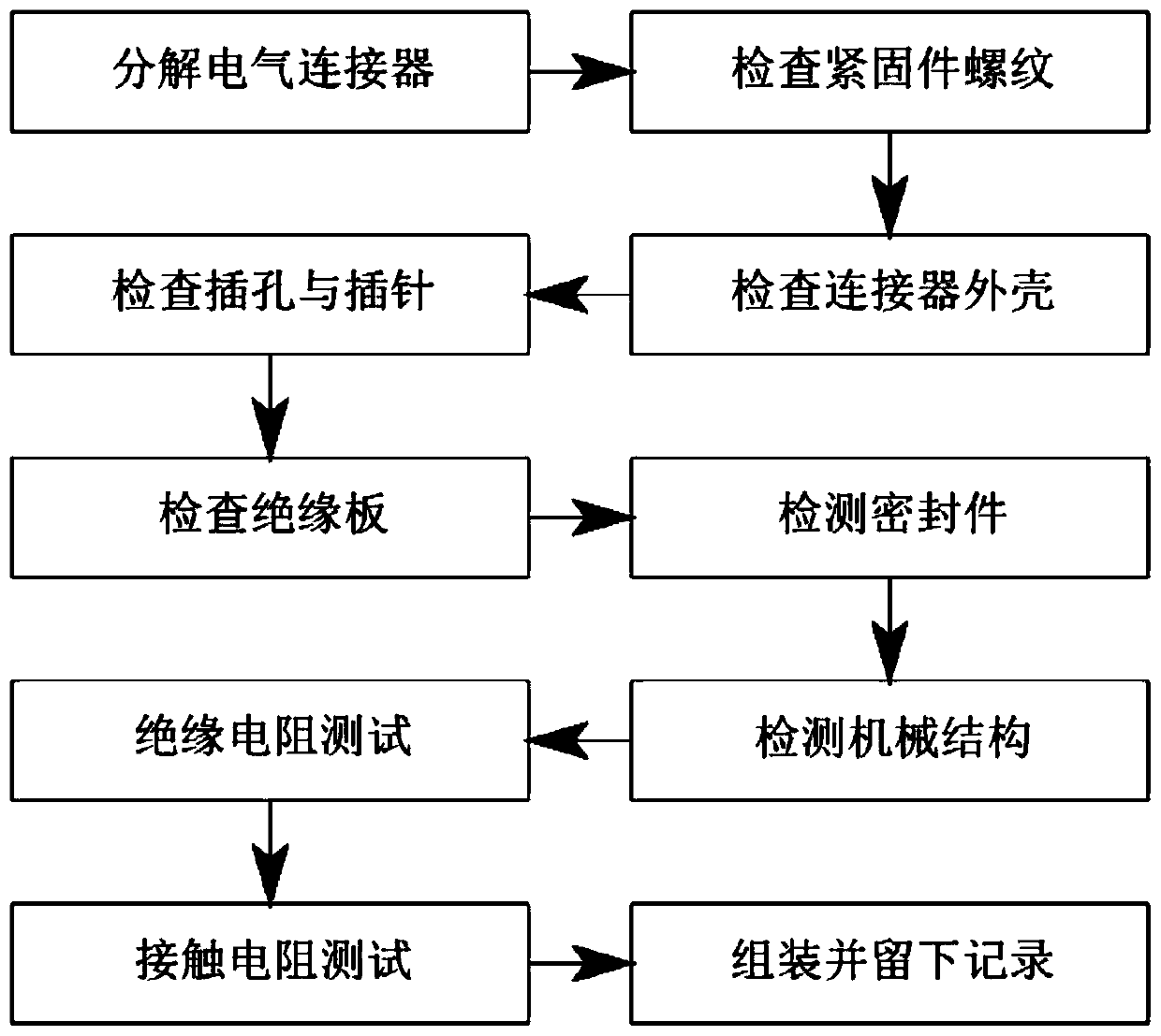

[0025] Such as figure 1 A method for overhauling a tram electric connector is shown, the steps of the method are,

[0026] S1. Decompose the electrical connector. The electrical connector is fixed on the tram through fasteners. In the process of decomposing the electrical connector, the fasteners of different electrical connectors need to be stored separately to avoid mixed installation; The connector is composed of a shell, pins, jacks, insulating plates, seals and mechanical connection structures. During maintenance, not only the above structural parts must be overhauled, but also the insulation resistance and contact resistance at the pins and jacks. to test.

[0027] S2. Check the internal thread of the threaded hole of the fastener. Visual inspection, if there is a thread defect in the thread, the thread defect includes damage, corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com