Preparation method of anti-side-leakage pants-type paper diaper

A diaper and side leakage prevention technology, applied in the fields of medical science, clothing, underwear, etc., can solve the problems of poor comfort on all sides of side leakage prevention, achieve side leakage prevention and improvement of comfort, simple preparation process and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

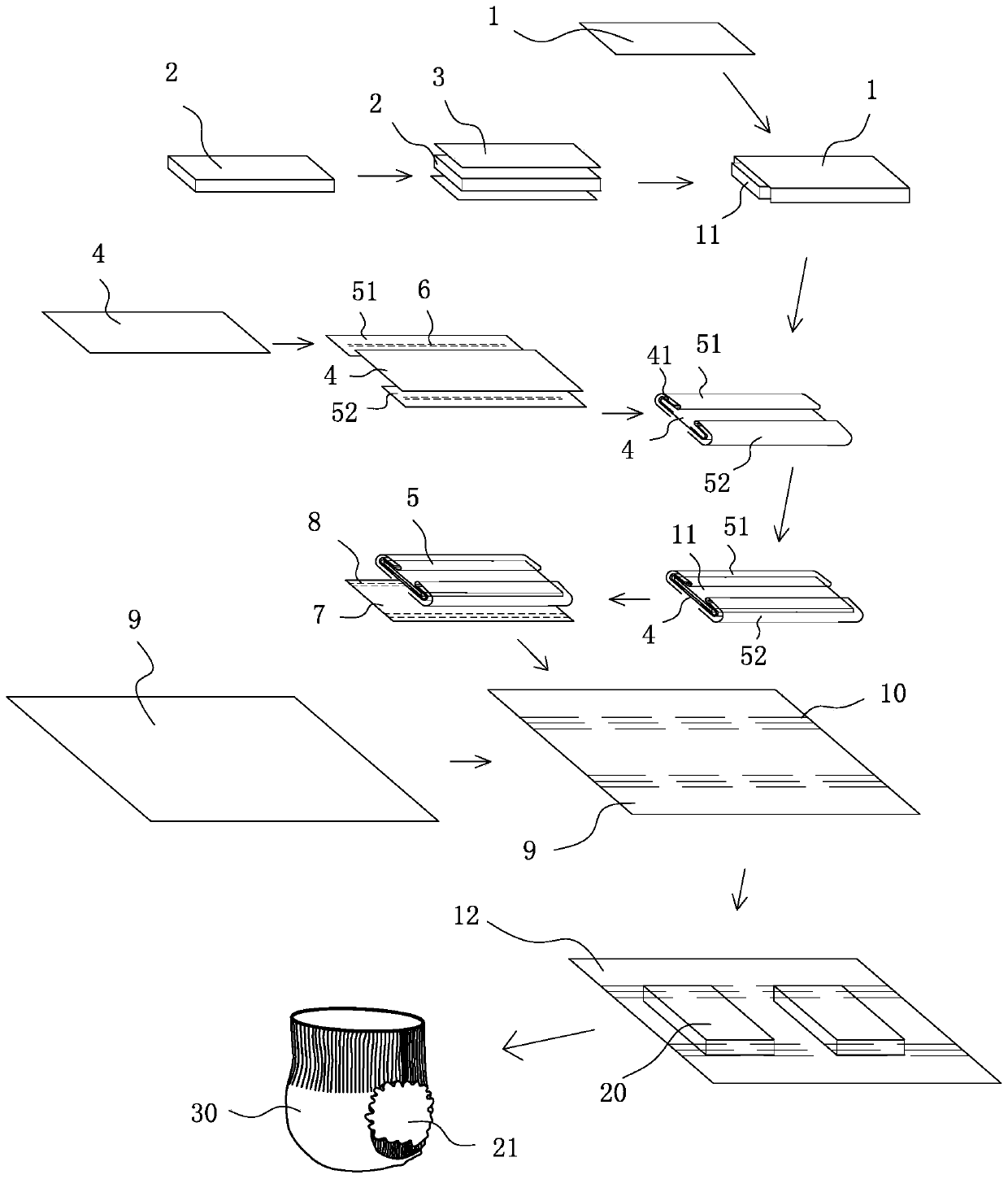

[0040] refer to figure 1 Shown, a kind of preparation method of anti-side leakage trousers type diaper comprises the following steps:

[0041] 1) Preparation of liquid-permeable surface layer:

[0042] Unwind the pre-produced roll-shaped hydrophilic non-woven fabric 1 and convey it along the direction of the preparation process of trouser-type diapers. Define the extending direction of the conveying direction of the hydrophilic non-woven fabric as the longitudinal direction, along the width of the hydrophilic non-woven fabric The direction in which the direction extends is the transverse direction;

[0043] 2) Prepare absorbent core layer 11:

[0044] a. Molding an absorbent core 2 through a forming die wheel, and the absorbent core 2 is made of a bulky non-woven fabric with a polymer water-absorbing resin;

[0045] b. Cover the upper surface and the lower surface of the product in step a with toilet paper 3;

[0046] 3) Adhere the horizontal middle part of the hydrophilic...

Embodiment 2

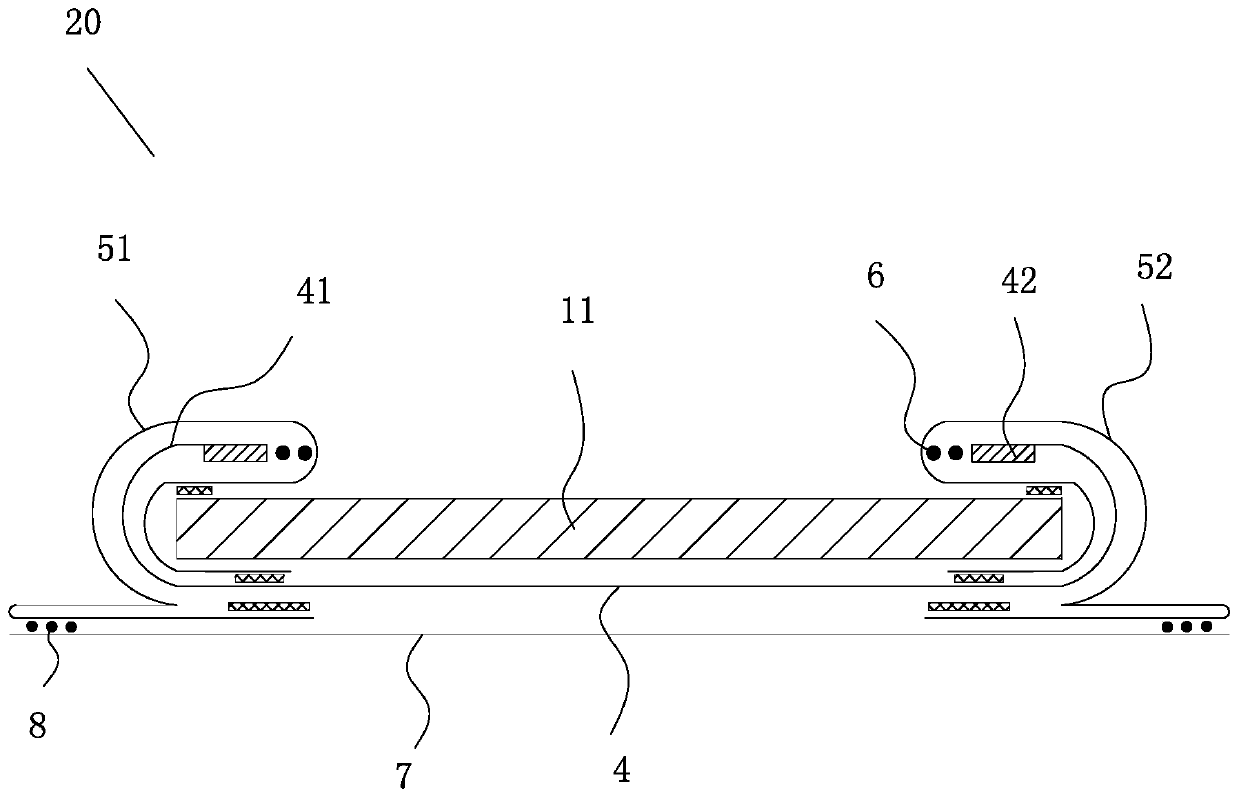

[0066] refer to figure 1 and figure 2 As shown, the second embodiment is further improved on the basis of the first embodiment, and its difference from the first embodiment is that: in the step 4 and step 5, the left hydrophobic non-woven fabric 51 and the right hydrophobic non-woven fabric Spray glue on the opposite surface of the woven fabric 52 and near the PE film 4, so that when the product in step 3 is cut and adhered to the upper surface of the product in step j, the left hydrophobic non-woven fabric 51 and the right hydrophobic non-woven fabric 52 The upper spray glue part adheres to the lateral sides on the upper surface of the liquid-permeable surface layer, so that the connection between the left hydrophobic non-woven fabric 51 and the right hydrophobic non-woven fabric 52 and the liquid-permeable surface layer is firm, and can better cover Covering the lateral sides of the absorbent core layer 11, so as to enhance the anti-side leakage performance.

[0067] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com