Improved hydraulic rivet machine

An improved riveting machine technology, which is applied in the field of hydraulic machinery, can solve problems affecting riveting speed, achieve the effects of improving riveting quality, improving riveting efficiency, and simplifying the riveting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

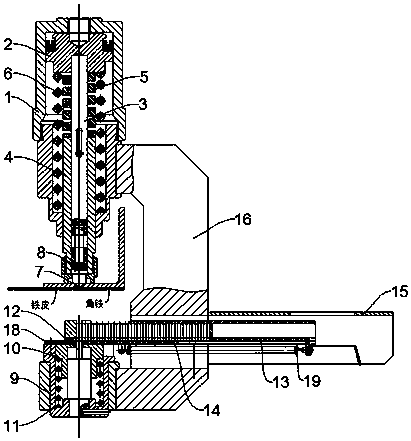

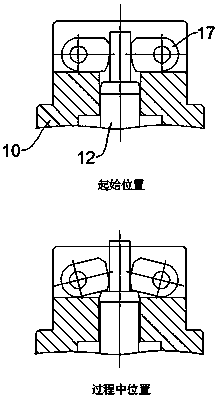

[0022] see Figure 2~3 , in the embodiment of the present invention, an improved hydraulic rivet machine includes a frame 16, and the two ends of the frame 16 are respectively equipped with a cylinder body 1 and a bracket 9, and the bracket 9 is provided with a rivet seat 10; The cylinder 1 is provided with a piston 2 and a composite piston rod matched with it, wherein the piston 2 is connected to the inner wall of the lower end of the cylinder 1 through a return spring 6. During operation, hydraulic oil enters the cylinder 1 and pushes the piston 2 to Moving down, the return spring 6 is compressed to realize the reset of the piston 2 later.

[0023] The composite piston rod includes a piston rod 3 and a piston rod outer casing 4 that is slidingly sleeved on the periphery of the piston rod 3, and the piston rod 3 and the piston rod outer casing 4 are axially limited by a cylindrical pin to prevent the piston rod outer casing 4 from contact with the piston rod outer casing 4. ...

Embodiment 2

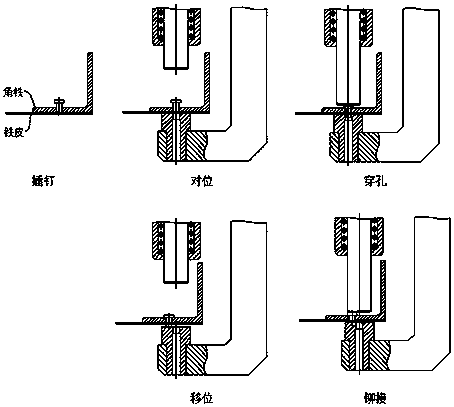

[0034] The embodiment of the present invention will carry out the description of the completion workflow of the rivet machine in conjunction with embodiment 1, specifically as follows:

[0035] 1) Install rivets

[0036] The rivets are installed in the rivet box 14, and the number of rivets that fill the rivet box 14 is 42. The rivet push plate 13 sends the rivets to the rivet seat 10 through elastic force, and the most front rivet is directly above the push rod 12. This implementation In the example, a rivet with a square end is used, and correspondingly, the upper end surface of the push rod 12 is also square.

[0037] 2) Counterpoint

[0038] Hold the frame 16 in hand, insert the lower part of the piston rod end 7 into the pre-punched hole of the angle iron and make the piston rod 3 substantially perpendicular to the end face of the angle iron hole, so that the rivet can be aligned with the hole on the angle iron, because the piston rod The thrust of the connection spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com