Flap type rudder structure

A flap rudder and flap technology, applied to steering gear, rudder steering, ships, etc., can solve the problems of increased ship total resistance, large frictional resistance, deterioration of ship speed and energy consumption level, etc., to reduce ship resistance , Increase the effect of rudder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

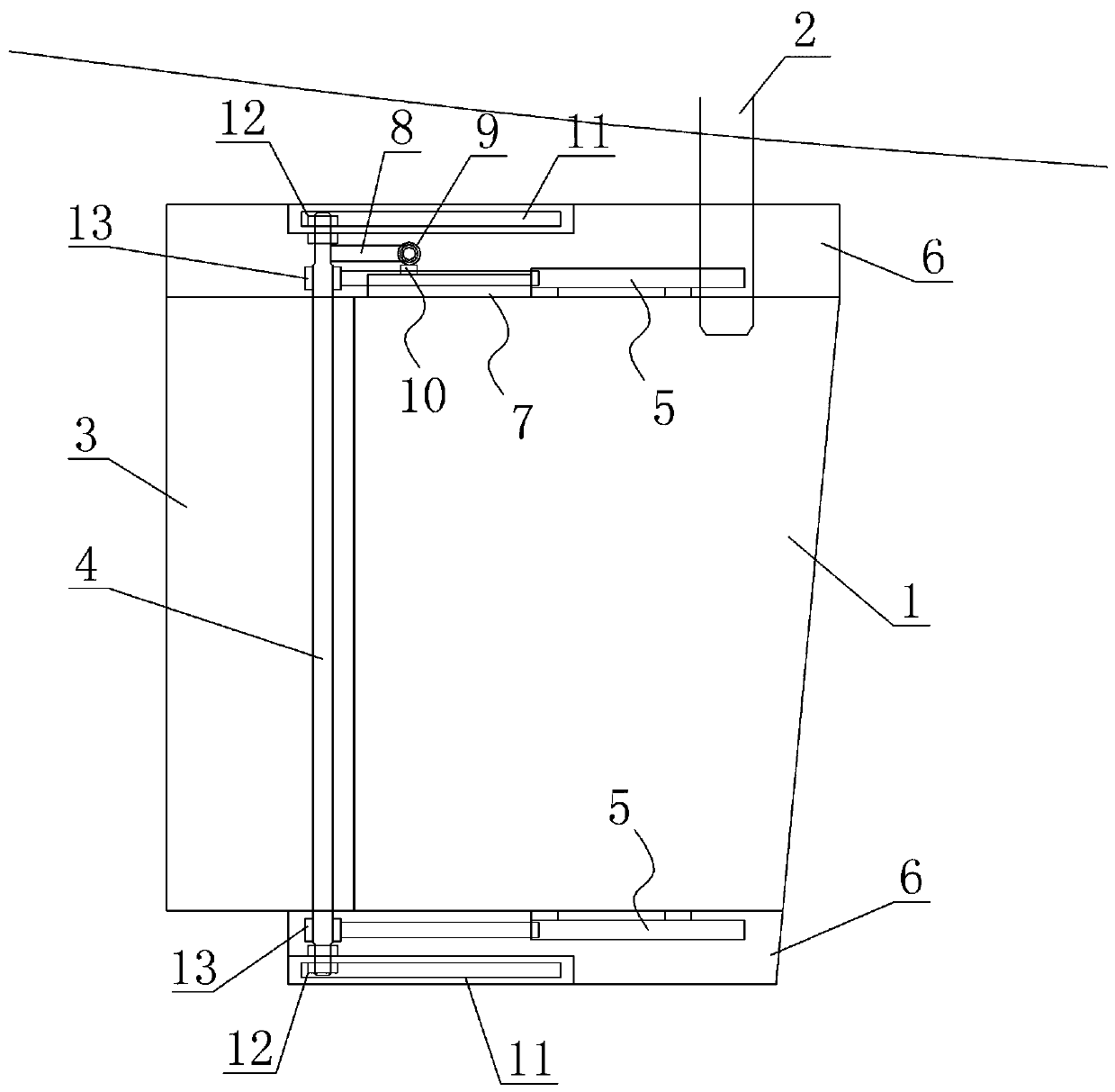

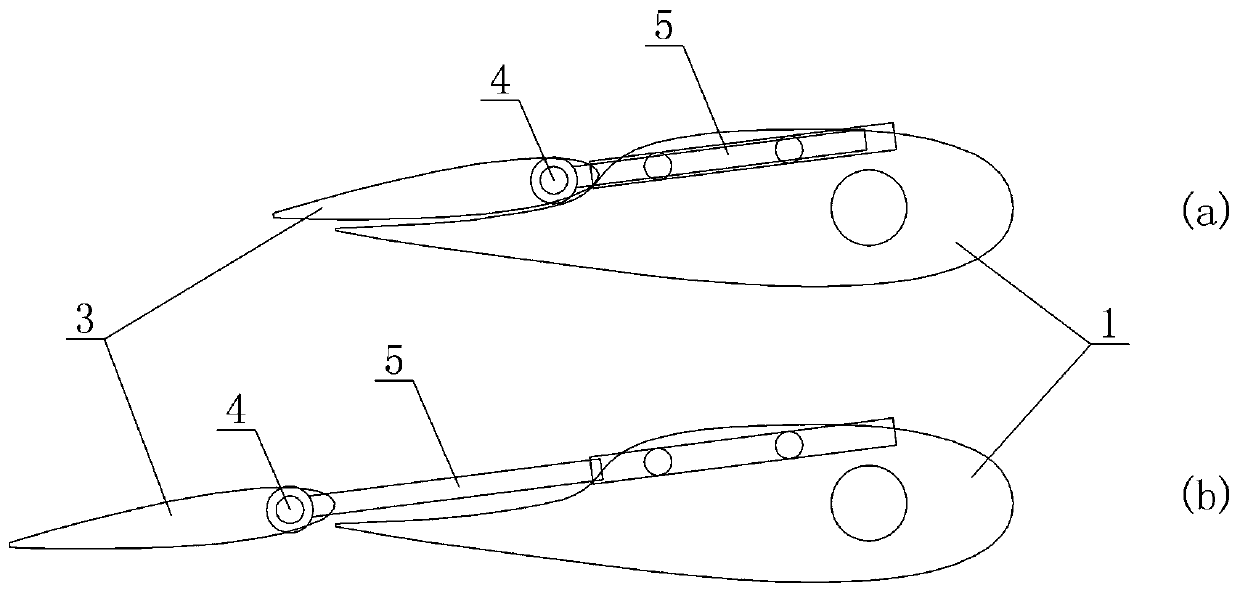

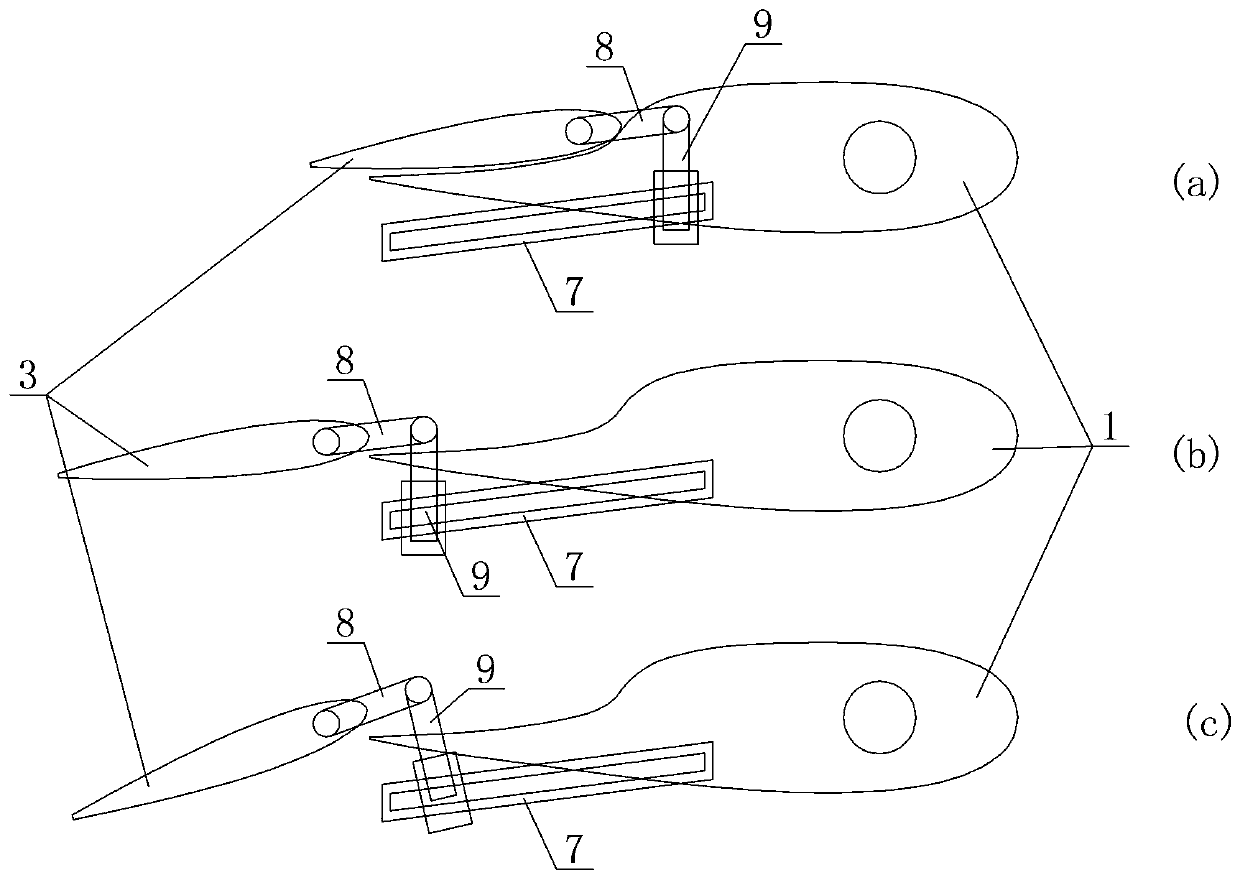

[0011] A flap rudder structure, including the main rudder blade 1 installed on the hull through the main rudder stock 2, and the flap 3 fixedly installed with the flap rudder stock 4, one side of the tail of the main rudder blade is concave inward in an arc shape , the flap is arranged in the arc-shaped depression of the main rudder blade, and the flap and the main rudder blade are in a symmetrical wing shape as a whole; the top and bottom of the main rudder blade are respectively equipped with telescopic telescopic rods 5, and the ends of the two telescopic rods are respectively Hinged with the two ends of the flap rudder stock, the top and bottom of the main rudder blades are respectively equipped with rudder cover 6, the guide rail 7 is arranged in the rudder cover in a direction parallel to the telescopic direction of the telescopic rod, and one end of the flap rudder stock A pole 8 is connected, and one end of a telescopic drive rod 9 is hinged with the pole and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com