A feed ball structure for a fish pond aquaculture jet feeding device

A technology of ball structure and feed, which is applied in application, fish farming, climate change adaptation, etc., can solve the problems of a lot of time-consuming, short spraying distance of the spray head, low feeding efficiency, etc., and achieve the effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

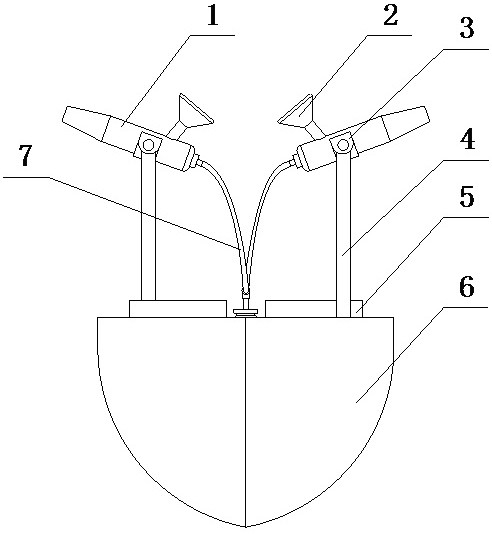

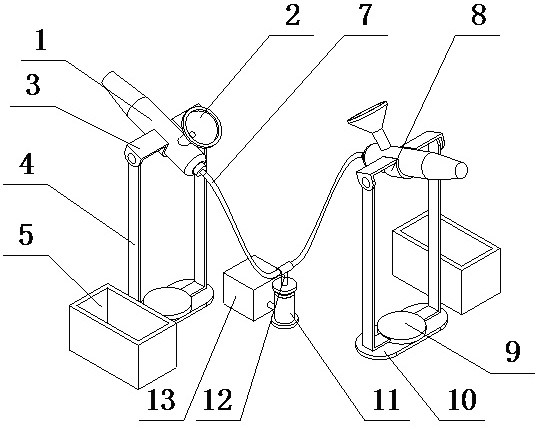

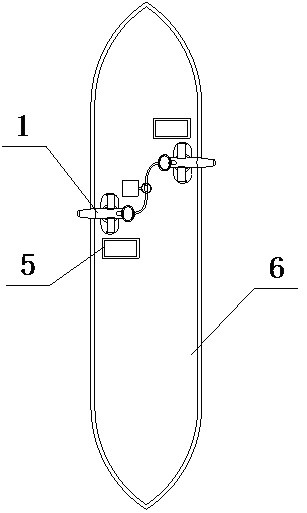

[0022] A feed ball structure for a fish pond breeding jet feeding device of the present invention is realized in the following way: a feed ball structure for a fish pond breeding jet feeding device of the present invention consists of hinged ears (15), main ball sleeves (16), air holes (17), water stop strip (18), auxiliary ball sleeve (19), acid source granules (20), feed (21), alkali source granules (22), splicing strip (23), accommodation cavity (24) and Filling body (25), the main ball sleeve (16) is a hemispherical sleeve, the auxiliary ball sleeve (19) is a hemispherical sleeve, and the main ball sleeve (16) and auxiliary ball sleeve (19) are hinged The sleeves are hinged and spliced to form a whole ball sleeve. A water stop strip (18) is placed between the gap between the main ball sleeve (16) and the auxiliary ball sleeve (19), and at least one insert is placed on the main ball sleeve (16). Connecting strips (23), on the auxiliary ball sleeve (19) there is an inserti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com