Rear suspension line lower adjusting tool structure

A technology for adjusting tooling and hanging wires, which is applied in the field of adjusting tooling structures under the rear suspension wires, can solve the problems of increasing the cost of detection line equipment, complicated manufacturing, and good vehicle comfort, so as to improve the assembly accuracy of the rear suspension and reduce the equipment cost. Cost, the effect of reducing the transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the rear under-suspension adjustment tool of the present invention will be further described below in conjunction with specific embodiments, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

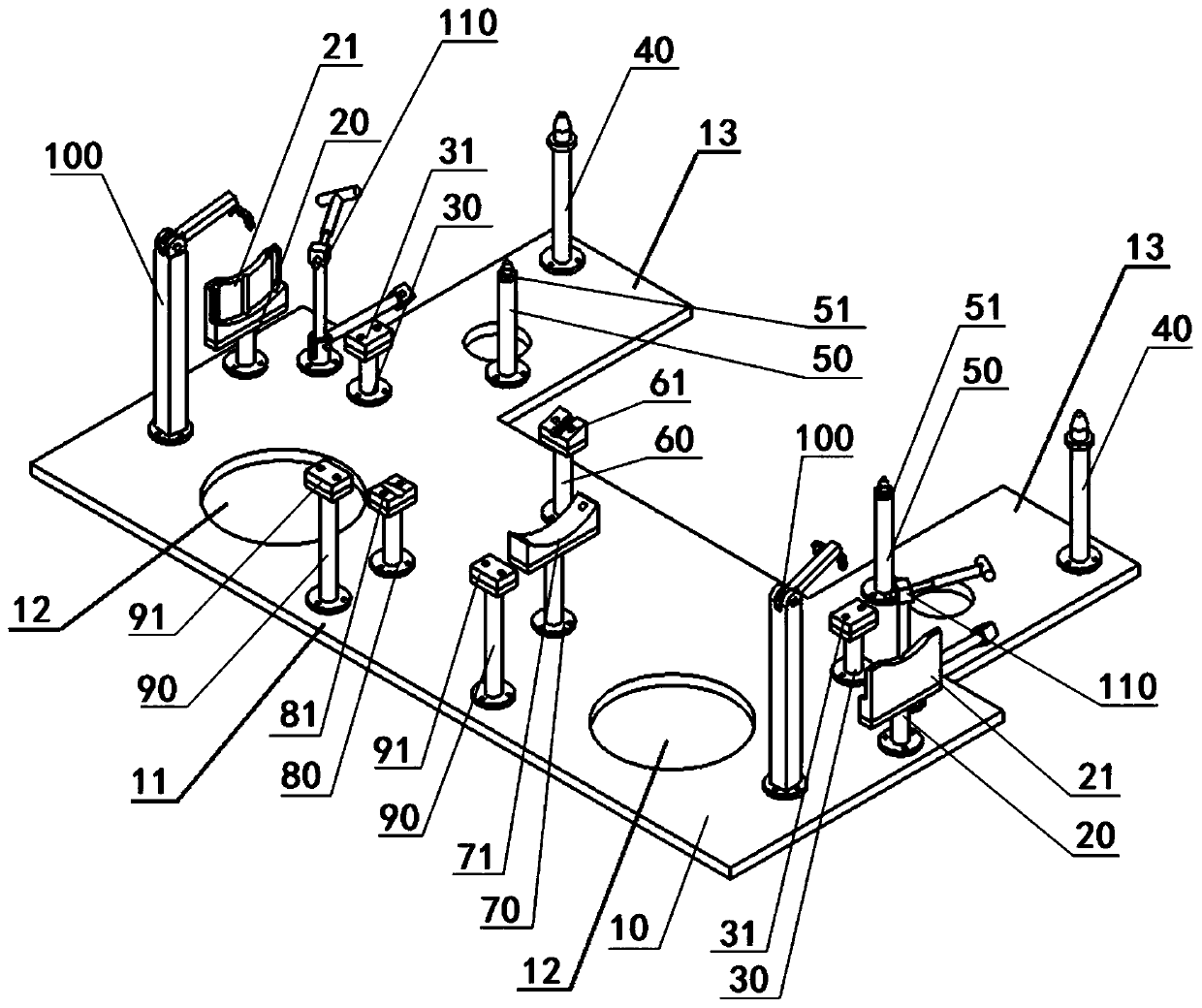

[0028] This embodiment provides a rear suspension adjustment tooling structure, such as figure 1 As shown, it includes a base plate 10, the base plate 10 has an axisymmetric structure, it includes a base plate main body 11 and a pair of extension plates 13 symmetrically arranged on both sides of the rear end of the base plate main body 11, and the base plate main body 11 is provided with Through hole 12. A pair of rear sub-frame auxiliary support structures 90 are symmetrically arranged on both sides of the front middle part of the base plate main body 11, and a pair of rear camber positioning structures 100 are symmetrically arranged on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com