An auxiliary device for flexible manufacturing and assembly welding of commercial vehicle half-axis sensors

An auxiliary device and sensor technology, applied in auxiliary devices, welding/cutting auxiliary equipment, quenching devices, etc., can solve the problems of uneven quenching and hardening layer of half-shaft workpiece, welding deformation, welding deviation, etc., and achieve good general-purpose and Adjustable flexibility, improve quenching quality, and ensure the effect of production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

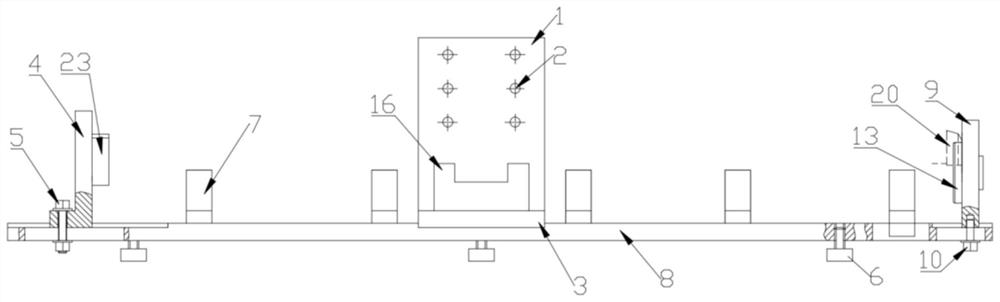

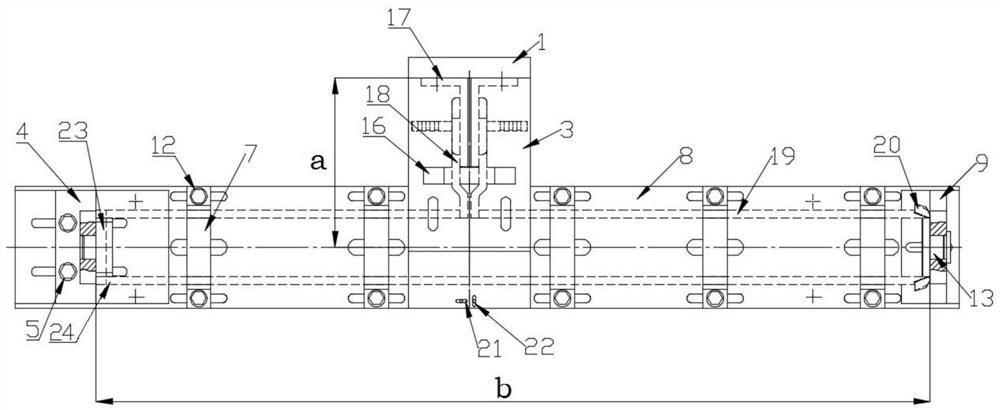

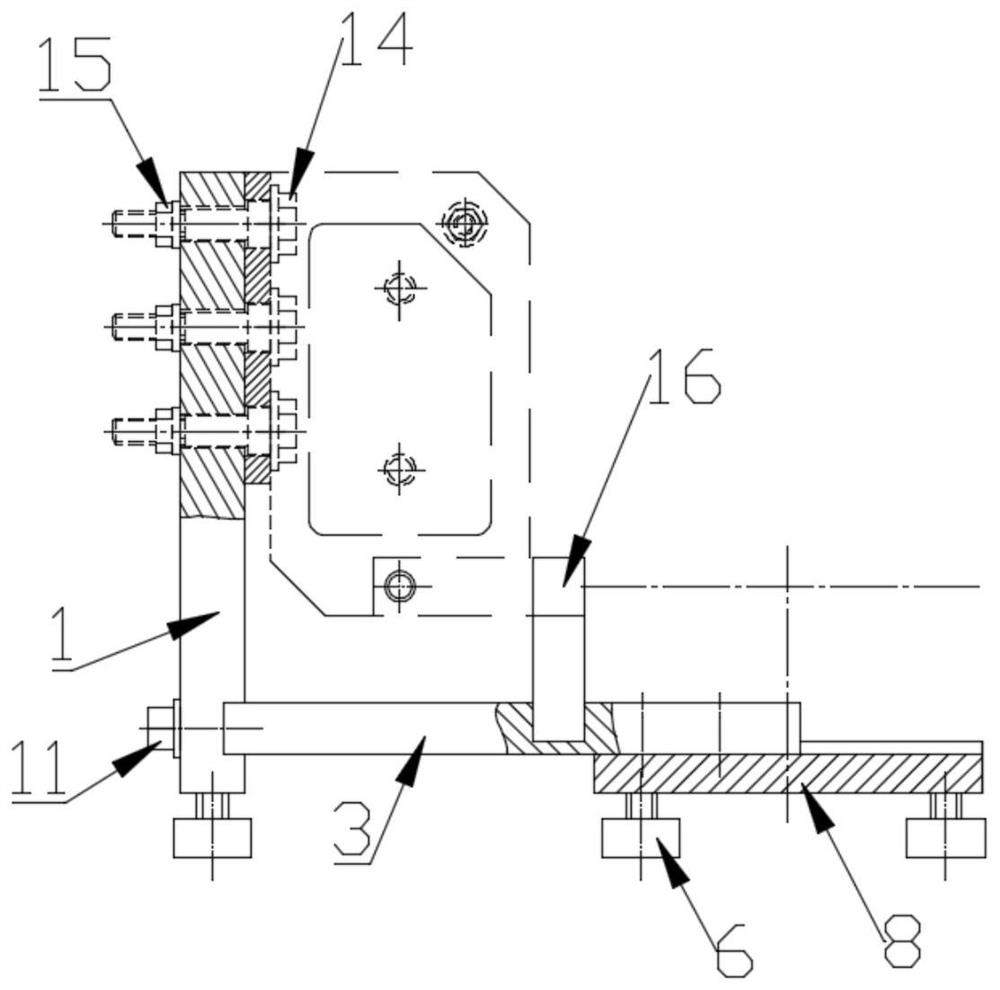

[0048] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0049] Such as figure 1 and figure 2 As shown, the present invention provides an auxiliary device for the flexible manufacture and assembly welding of commercial vehicle semi-axis sensors, which consists of a fixed vertical plate 1, an adjustment plate 3, a transition wire support seat 16, a base 8, and a spline end heating wire Adjustment seat 4, rectangular heating wire adjustment block 23, shaft diameter heating wire adjustment seat 7, flange end heating wire adjustment seat 9, arc heating wire adjustment block 13, axial level 21, radial level 22 and adjustment screw 6 composition.

[0050] Such as figure 1 and figure 2 As shown, the base 8 is used as the base of the entire auxiliary device, the main body of the base 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com