Tool eccentricity offline adjusting method based on robot spiral hole milling platform

A helical milling hole and adjustment method technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of inconvenient tool change, hindering the popularization and application of robot helical milling holes, and heavy weight of helical milling actuators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

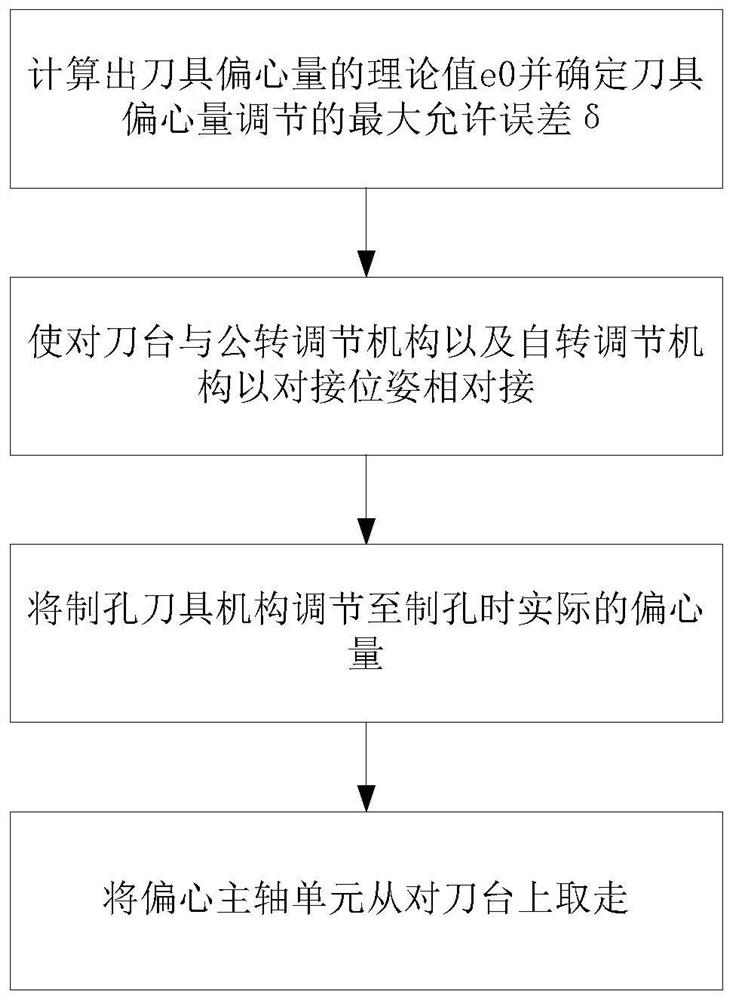

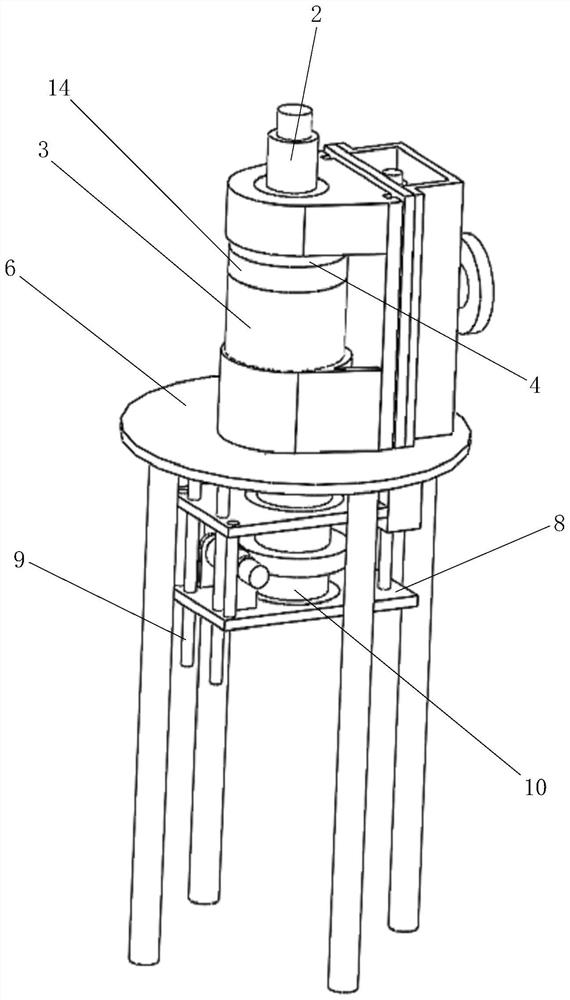

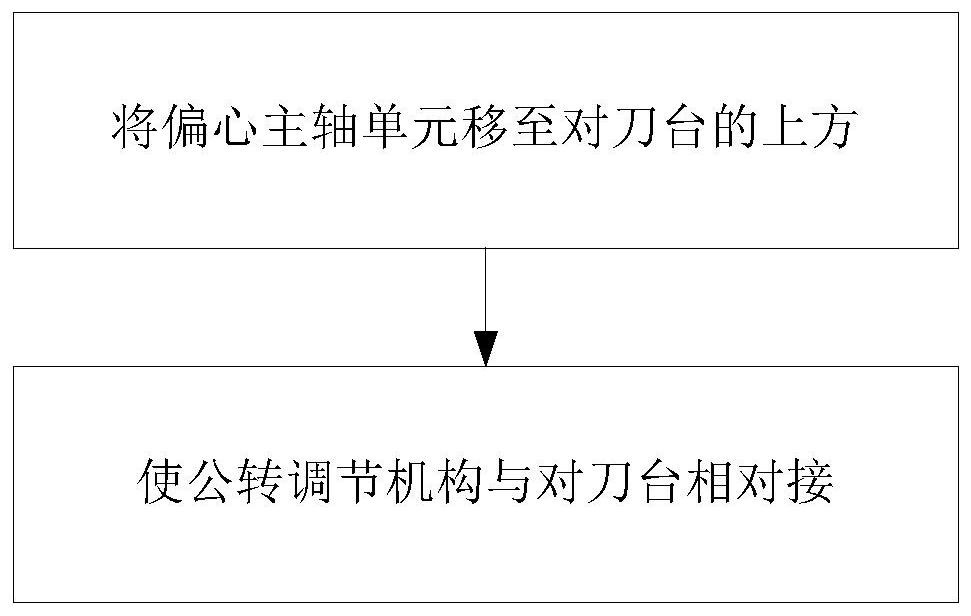

[0043] Such as figure 1 with 2 As shown, the off-line adjustment method of tool eccentricity based on the robot helical milling platform of the present invention, the robot helical milling platform includes a feed mechanism, a revolution drive mechanism, an eccentric spindle unit, a quick docking module, and a hole-making tool The mechanism and the tool setting table; the eccentric spindle unit includes the revolution adjustment mechanism and the rotation adjustment mechanism; the rotation adjustment mechanism is eccentrically rotated and installed on the revolution adjustment mechanism; The drive mechanism is detachably docked with the revolution adjustment mechanism through the quick docking module, the feed mechanism drives the revolution drive mechanism and the revolution adjustment mechanism for axial displacement, and the revolution drive mechanism drives the revolution adjustment mechanism through the quick docking module to perform revolution adjustment; hole making T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com