Integrated sand mixer and sand mixing method

A sand mixer and sand mixing technology, which is applied in the field of machinery, can solve problems affecting normal production, high temperature rise, and cleaning difficulties, and achieve the effects of shortened sand mixing time, excellent uniformity, and short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

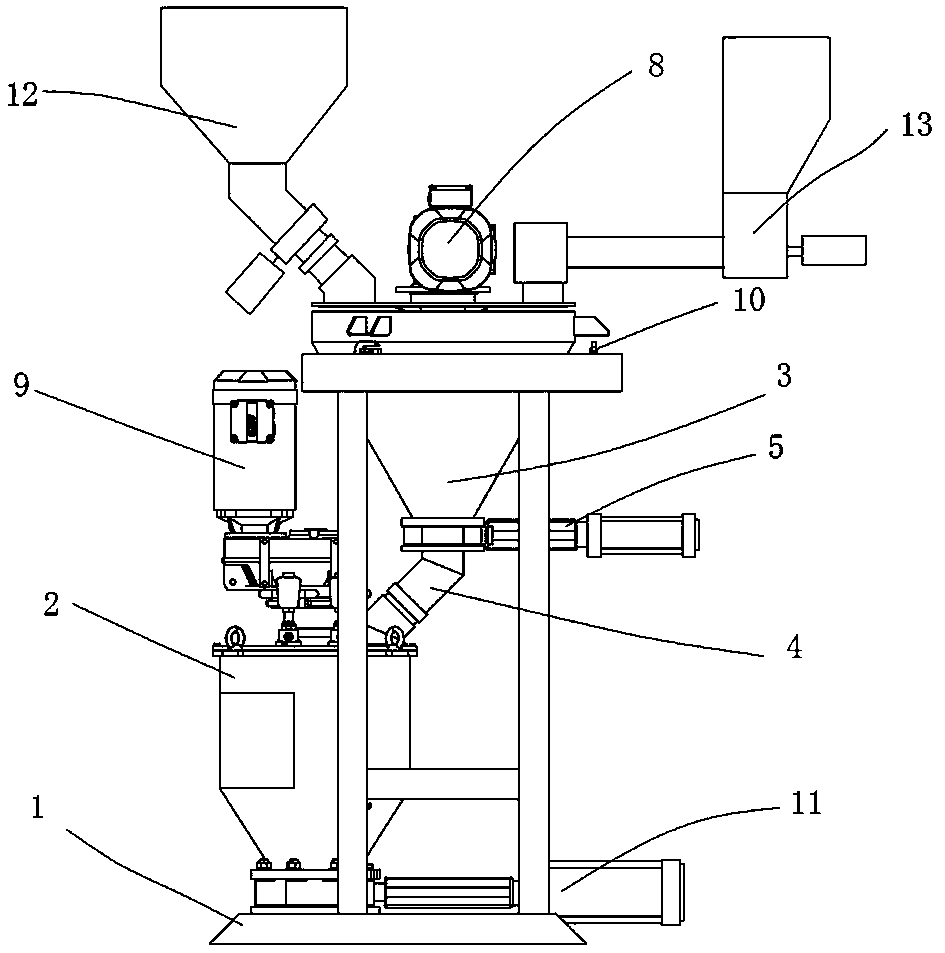

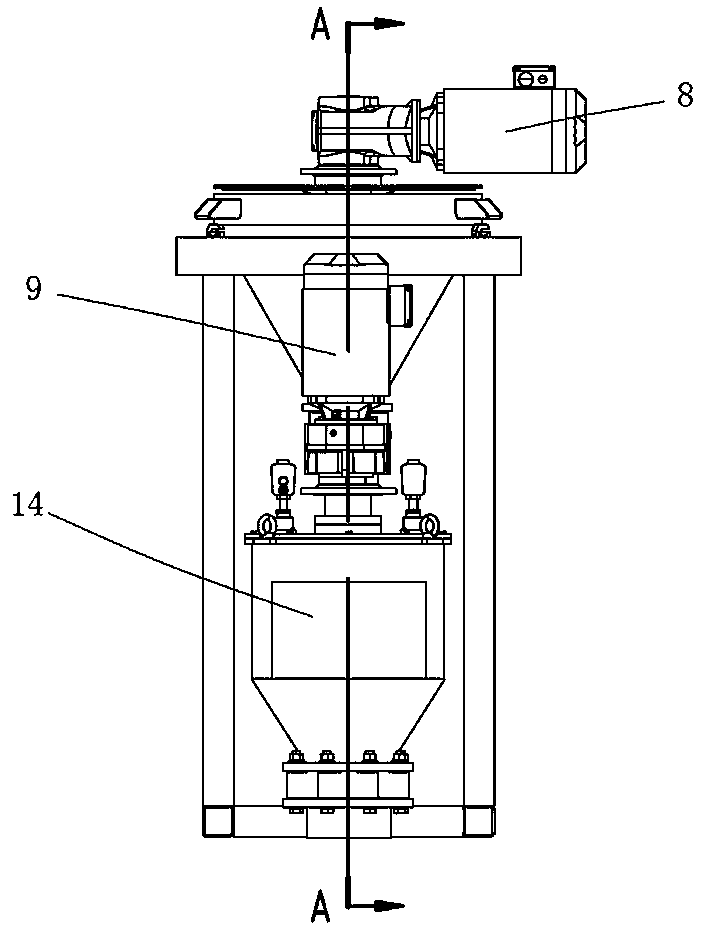

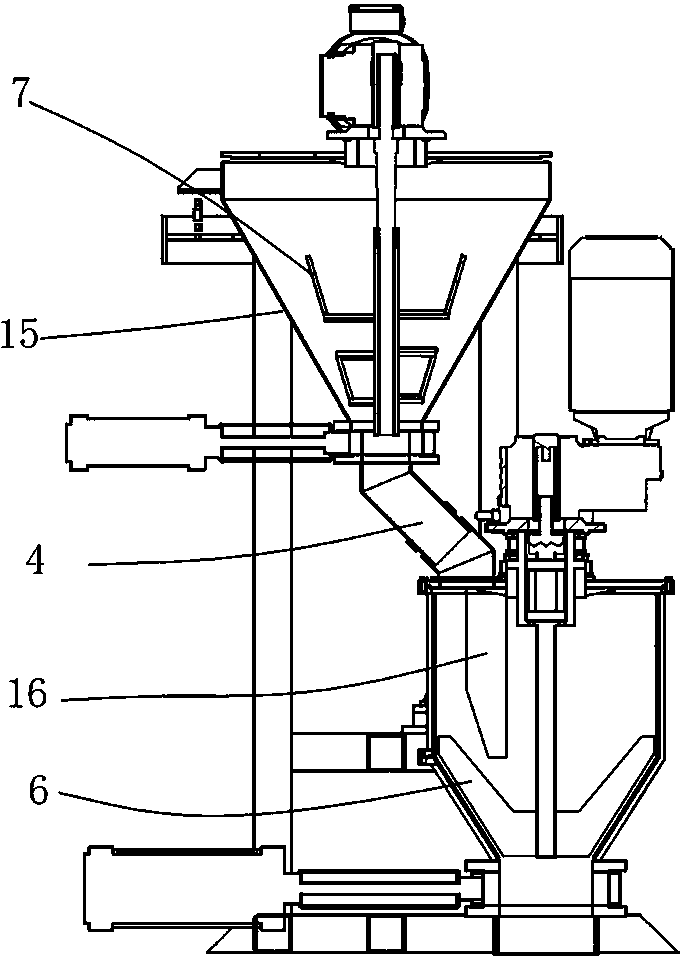

[0042] Embodiment one: see Figure 1 to Figure 3 As shown, an integrated sand mixer includes a frame 1, a final mixing cylinder 2 arranged on the frame, a premixing cylinder 3 arranged above the side of the final mixing cylinder 2, and the outlet at the bottom of the premixing cylinder 3 passes through the The sand pipe 4 is connected to the top feed port of the final mixing cylinder 2, and the sand slide pipe 4 is provided with a knife gate valve 5.

[0043] The premixing barrel 3 is a conical bucket, the upper part of which is connected with a sand bucket 12 and a powder quantitative device 13, and a premixing blade 7 is arranged in the conical bucket, and the premixing blade 7 is driven by a premixing power mechanism 8, and the premixing power mechanism 8 can be composed of a motor and a corresponding deceleration mechanism, and a load cell 10 is arranged on the frame in cooperation with the premixing cylinder 7 . The lower part of the final mixing cylinder 2 is a conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com