A cyclic stretching and mixing method and equipment for polymer nanocomposite materials

A nano-composite material and polymer technology, applied in the field of cyclic stretching and mixing of polymer nano-composite materials, can solve the problems of difficulty in ensuring particle dispersion uniformity, poor dispersion effect, large gap, etc., and achieve enhanced mixing and mixing Strength and effect, effect of excellent dispersing and mixing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

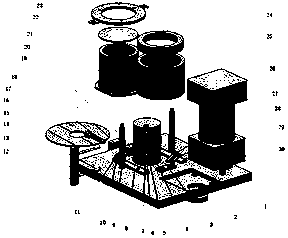

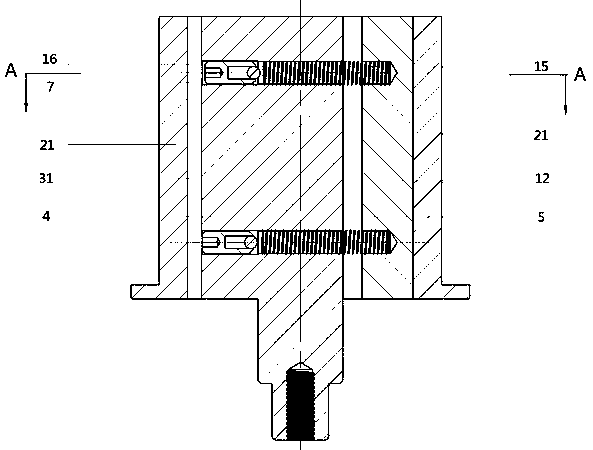

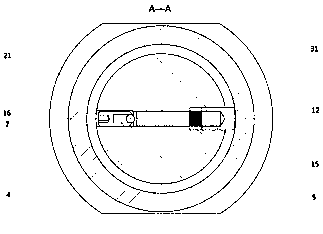

[0036] refer to Figure 1~Figure 9 , the present invention provides a method and equipment for cyclic stretching and mixing of polymer nanocomposites. The controllable stretching force field is generated by adjusting the eccentricity between the barrel and the rotor. With the rotation of the rotor, the rotor The blades on the top are always tightly attached to the inner wall of the barrel under the action of the spring, and the polymer nanocomposite is forced to melt, plasticize, disperse and mix, specifically including the following steps:

[0037] (1) Slide the cylinder 21 along the chute between the limit block 3 and the limit block 29 to a certain eccentric distance from the rotor 4, fix the cylinder 21 on the bottom plate 1, heat the equipment to the polymer processing temperature, and After the polymer nanocomposite material enters the mixing chamber from the upper end surface of the barrel 21, the upper end surface of the barrel 21 is sealed, and the rotor 4 rotates, dr...

Embodiment 2

[0045] This embodiment is a method and equipment for cyclic stretching and mixing of polymer nanocomposites. The difference from Example 1 is that the size of the eccentric distance between the barrel 21 and the rotor 4 determines the strength of the tensile force field, and the size of the eccentric distance between the barrel 21 and the rotor 4 can be determined before melting and kneading. It cannot be adjusted during the melting and mixing process; the speed of the rotor 4 determines the frequency of the tensile force field, and the speed of the rotor 4 can be adjusted during the mixing process; the length of the mixing time determines the tensile force The length of the field duration and the length of the mixing time can also be adjusted during the mixing process; the eccentric distance between the barrel 21 and the rotor 4, the speed of the rotor 4, and the mixing time are different among the three tensile force field characteristics. The combination of different partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com