Shell performance test bench of automobile transmission shaft

A technology of transmission shaft and test bench, which is applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problem of undiscovered dust cover durability, etc., and achieve simple structure, convenient processing and compact installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

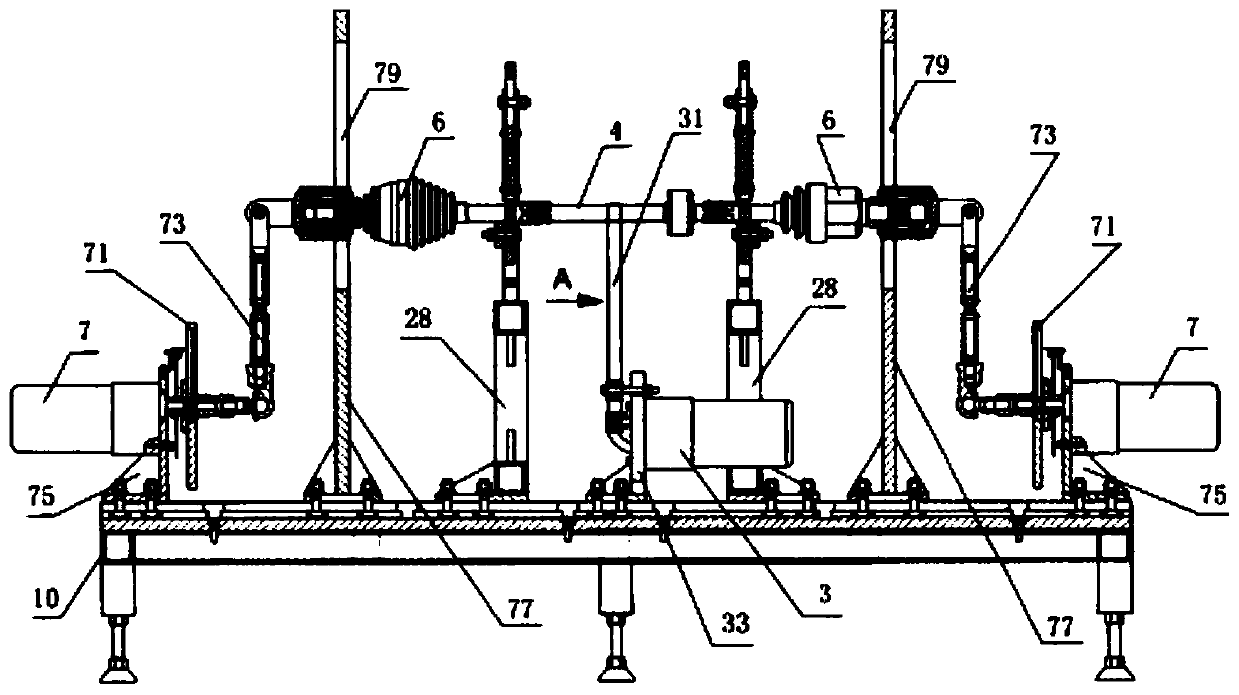

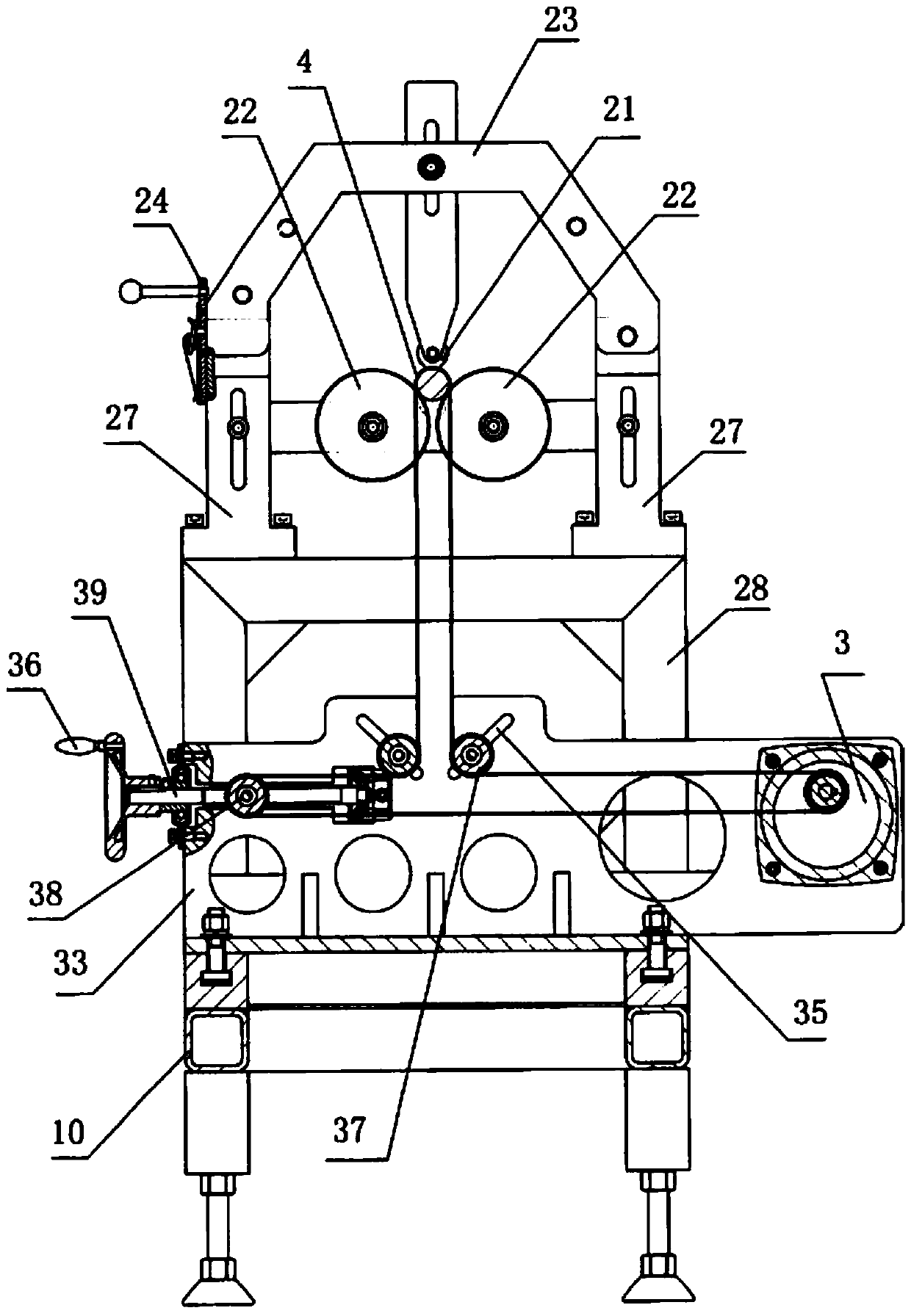

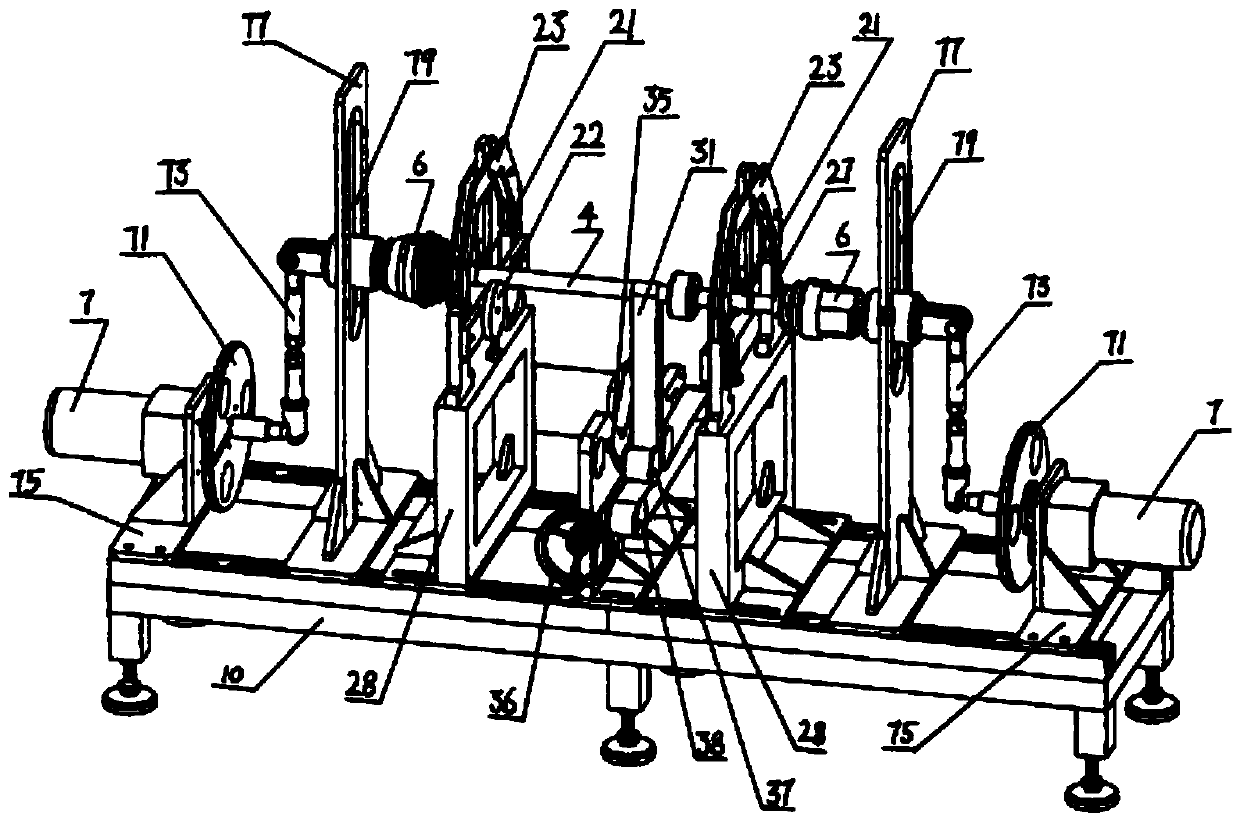

[0019] Please refer to Figure 1 to Figure 3 , the automobile dustproof cover test bench of the present invention mainly comprises the clamping mechanism that is used for clamping transmission shaft 4, the transmission mechanism that drives transmission shaft 4 to rotate, the swing mechanism that drives universal joint 6 deflection, guide plate 7, is formed with The underframe 10 of the T-shaped groove. in:

[0020] This transmission mechanism is installed in the middle part of underframe 10, mainly is made up of a transmission motor 3, belt 31 and fixed plate 33, and the bottom of this fixed plate 33 and this underframe 10 are connected by T-shaped groove (or dovetail groove) And threaded, so that the fixed plate 33 can be disassembled and fixed on the chassis 10 movably, a V-shaped groove 35 is formed in the vertical direction of the middle part of the fixed plate 33, and the V-shaped groove 35 is symmetrical and Two idler wheels 37 can be disassembled and fixed, and a lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com