Protective film and preparation method thereof

A technology of protective film and adhesive layer, applied in the direction of film/sheet adhesive, conductive adhesive, adhesive, etc., can solve the problems of antistatic agent precipitation of protective film, easy to generate a large amount of static electricity, etc., to speed up static electricity consumption Dispersion speed, maintaining physical properties, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

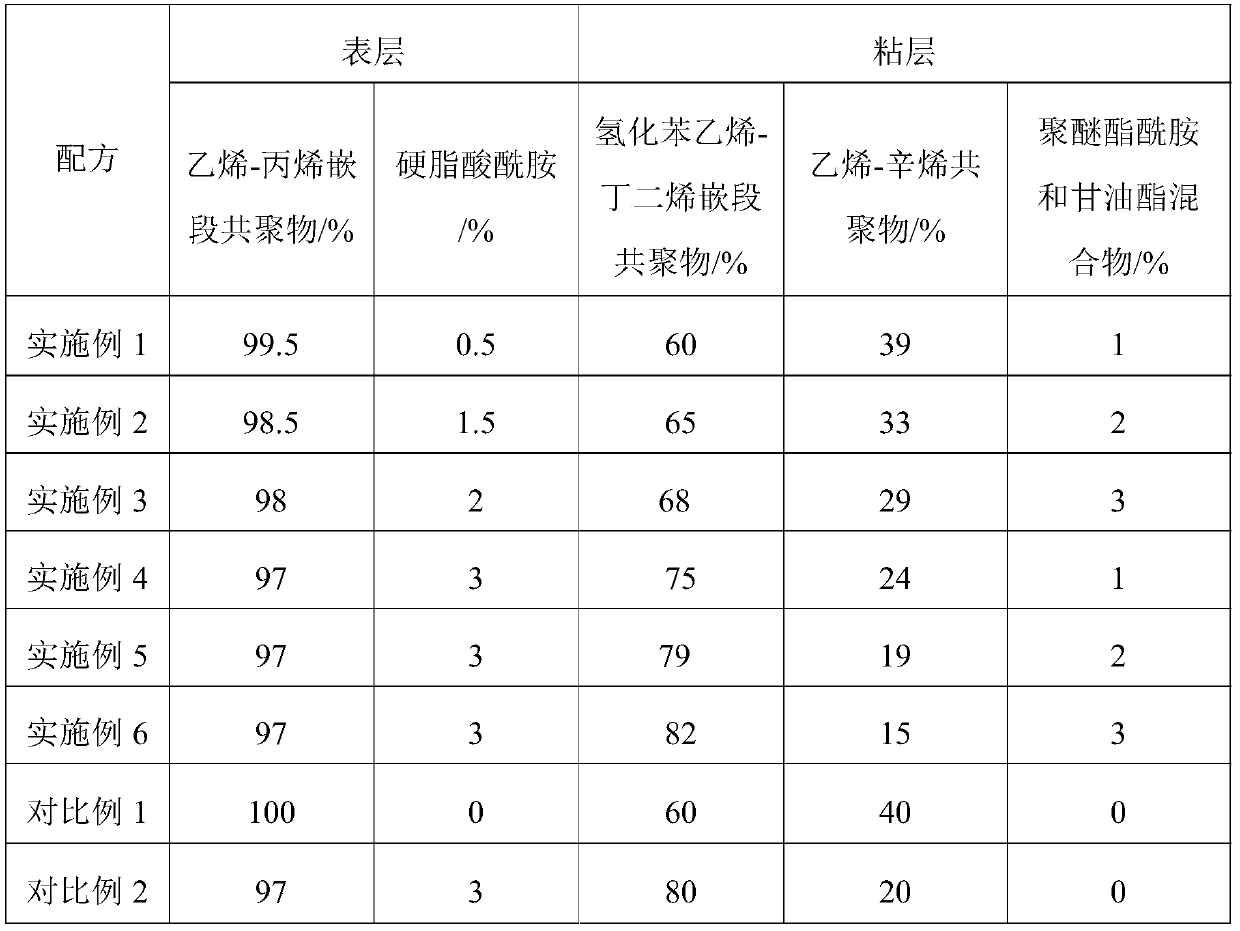

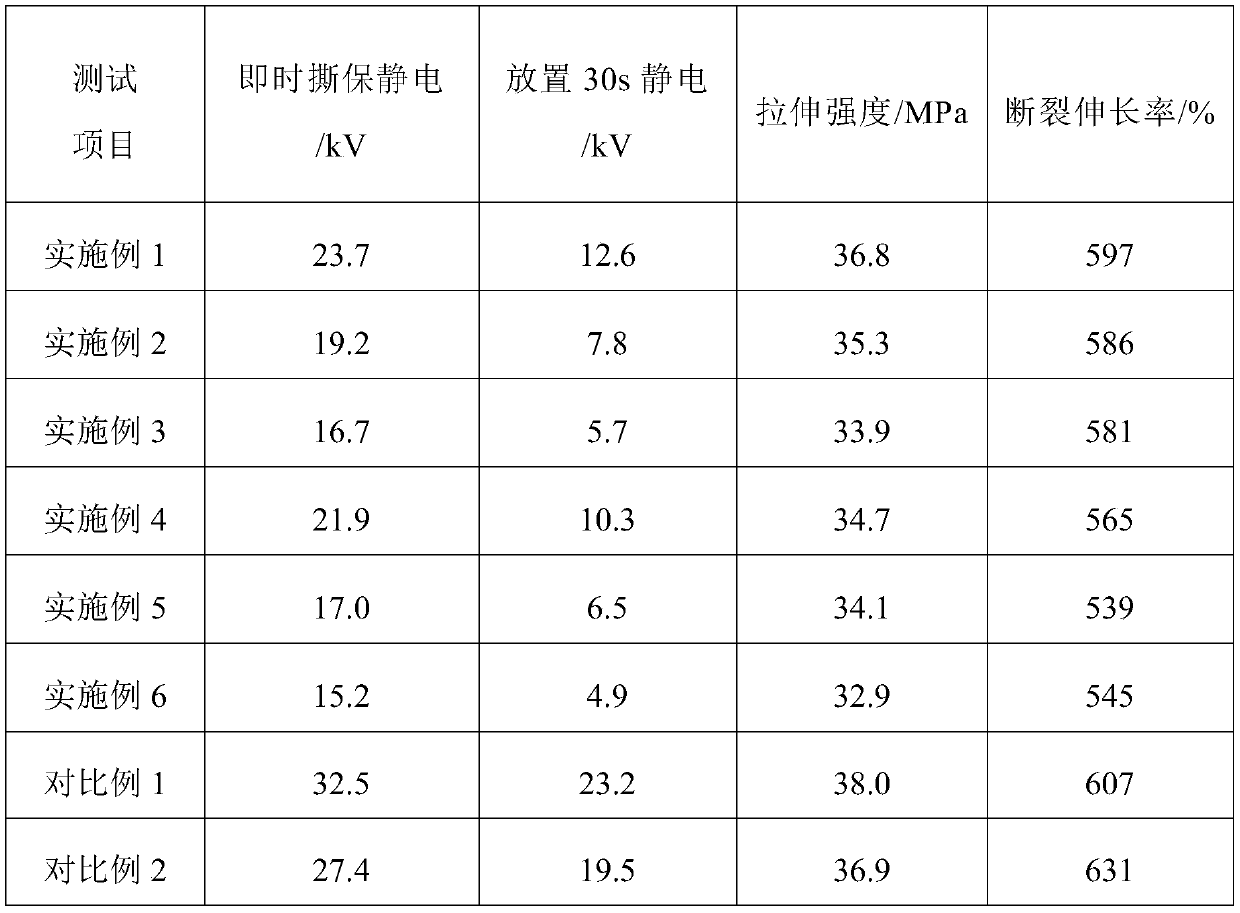

Embodiment 1

[0038] The protective film provided by the invention sequentially includes a surface layer, a core layer and an adhesive layer. The surface layer is made of ethylene-propylene block copolymer and stearic acid amide in a weight ratio of 99.5:0.5. The density of ethylene-propylene block copolymer is 0.90g / cm 3 , The melt index is 9.0g / 10min.

[0039] The core layer is made of ethylene-propylene block copolymer with a density of 0.90g / cm 3 , The melt index is 9.0g / 10min.

[0040] The adhesive layer is made of hydrogenated styrene-butadiene block copolymer, ethylene-octene copolymer and antistatic agent (a mixture of polyether ester amide and glyceride) in a weight ratio of 60:39:1 . The styrene content in the hydrogenated styrene-butadiene block copolymer is 13%, and the density is 0.90g / cm 3 . The density of ethylene-octene copolymer is 0.86g / cm 3 , The melt index is 5.0g / 10min. The weight ratio of polyether ester amide and glyceride is 1:1.

[0041] The surface layer h...

Embodiment 2

[0043] As the protective film provided in Example 1, the difference is:

[0044] The surface layer is made of ethylene-propylene block copolymer and stearic acid amide in a weight ratio of 98.5:1.5.

[0045] The adhesive layer is made of a mixture of hydrogenated styrene-butadiene block copolymer, ethylene-octene copolymer and antistatic agent (polyether ester amide and glycerol ester) in a weight ratio of 65:33:2 .

Embodiment 3

[0047] As the protective film provided in Example 1, the difference is:

[0048] The surface layer is made of ethylene-propylene block copolymer and stearic acid amide in a weight ratio of 98:2.

[0049] The adhesive layer is made of hydrogenated styrene-butadiene block copolymer, ethylene-octene copolymer and antistatic agent (a mixture of polyether ester amide and glyceride) in a weight ratio of 68:29:3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com