Subcritical rod carving method using source range detector signal as signal source

A Source Range Detector, Subcritical Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

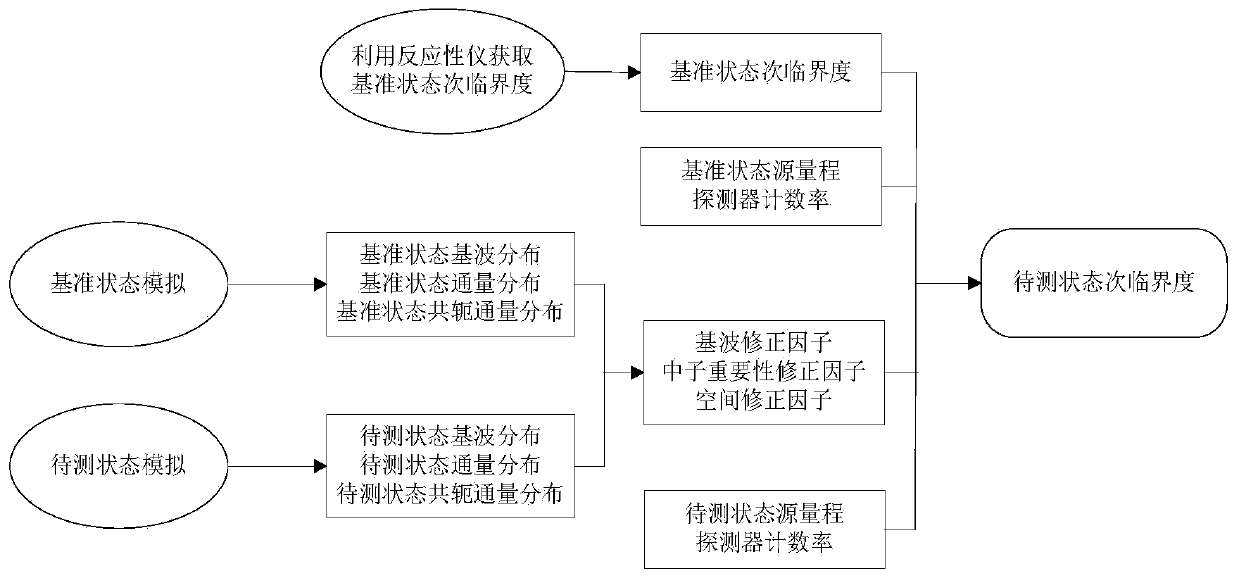

Method used

Image

Examples

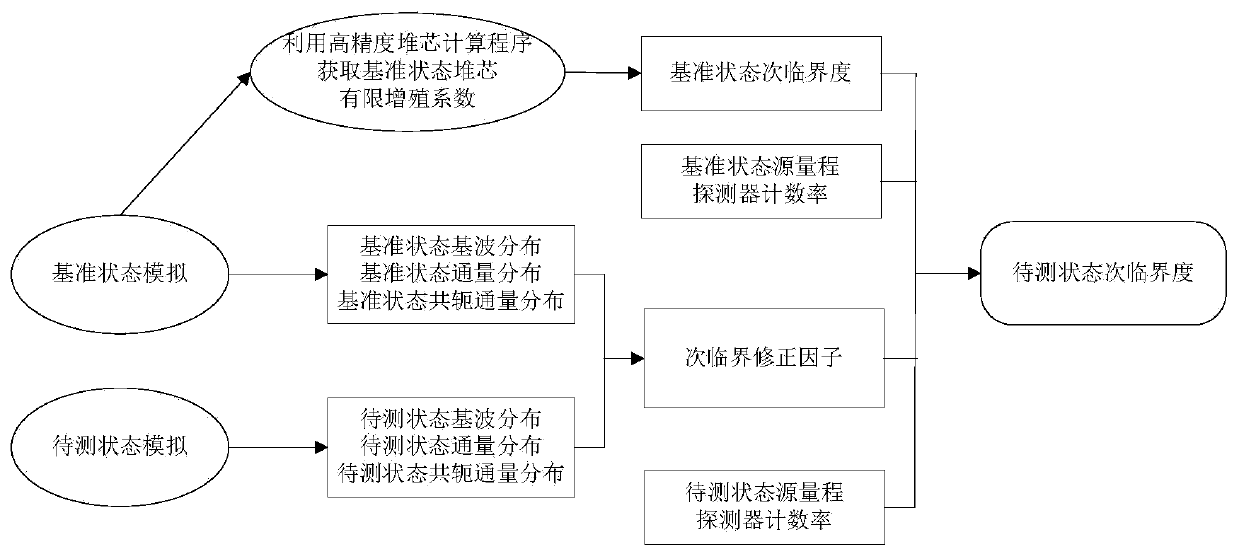

Embodiment 1

[0064] This embodiment provides a subcritical engraving method using the source range detector signal as the signal source, such as image 3 Shown: In the preparation stage of the subcritical indentation test, firstly through the reference state simulation, using the high-precision steady-state core calculation software that can fully consider the influence of external sources on the core neutron flux distribution in the subcritical state, calculate The finite multiplication coefficient of the core in the reference state is used to obtain the subcriticality of the core in the reference state, and generate key parameters including the fundamental wave distribution, flux distribution and conjugate flux distribution in the reference state; at the same time, each state to be tested can be performed The core simulation, using high-precision steady-state core calculation software that can fully consider the influence of external sources on the core neutron flux distribution in the subc...

Embodiment 2

[0086] As shown in Table 1 to Table 3, it is an embodiment of measuring the sub-criticality of the core in each rod state in the sub-criticality rod test of a certain group of control rods in a certain reactor according to the present invention.

[0087] Table 1 Source range detector count rate in each state

[0088]

[0089]

[0090] Table 2 Subcritical correction factor library prepared for two states to be tested

[0091] Core state Subcritical correction factor State to be tested 1#0.4500 State to be tested 2# 0.6085

[0092] Table 3 "Measurement" results of the finite multiplication coefficient of the core under test in the critical rod test

[0093]

[0094] Table 1 shows the count rate of the source range detector in each state, including the reference state and 2 states to be measured.

[0095] Table 2 is the subcritical correction factor library prepared for the two states to be tested in Table 1 before the subcritical bar test.

[0096] Table 3 shows the "measurement" res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com