rotating electrical machine

A technology for rotating electrical machines and stator cores, applied in electric components, electromechanical devices, electrical components, etc., can solve problems such as damage to insulating parts and short circuits, and achieve the effect of preventing damage to insulating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

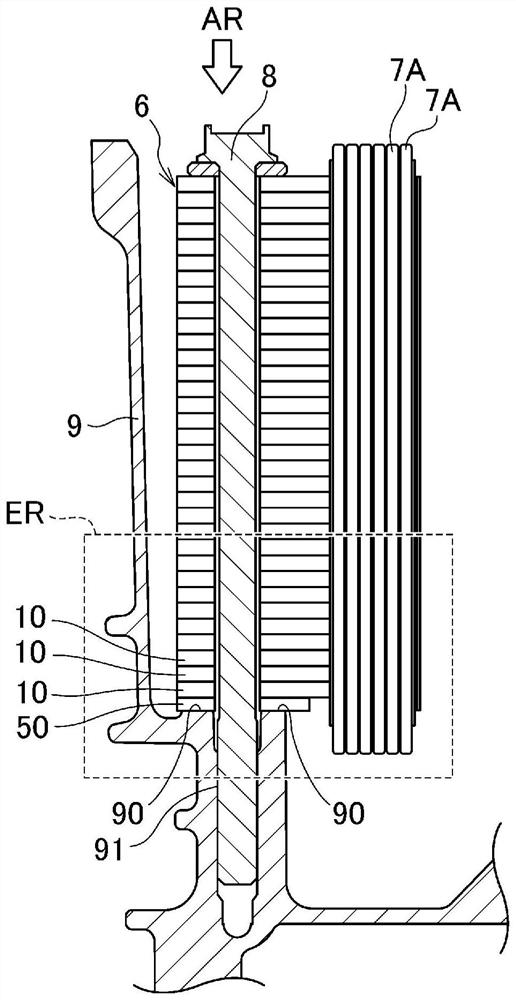

[0073] Hereinafter, one Embodiment of the rotating electrical machine of this invention is demonstrated based on drawing. The rotating electrical machine of the present invention includes at least a rotating electrical machine for generating and driving.

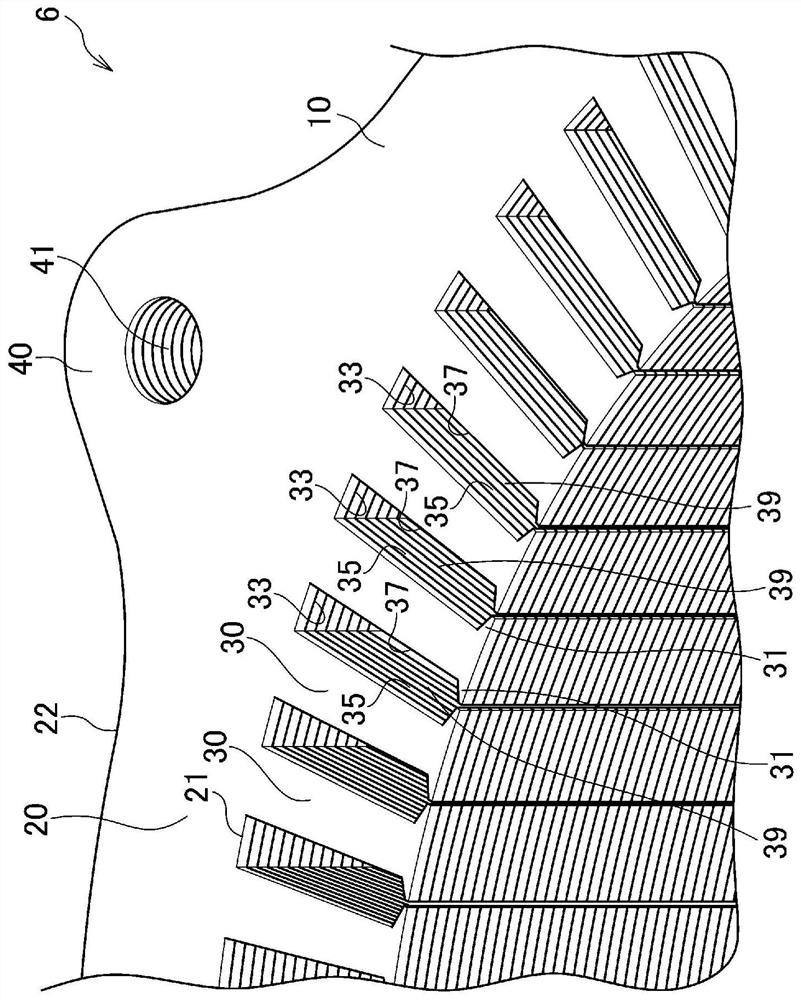

[0074] refer to Figure 1 to Figure 5 The rotating electrical machine 1 in one embodiment of the present invention will be described. In the drawings, in order to make it easier to see, only a part of the parts having a plurality of the same attributes may be denoted with reference signs. In addition, when components have the same shape, structure, etc., in order to facilitate understanding of the drawings, the same symbols may be respectively attached to the components.

[0075]

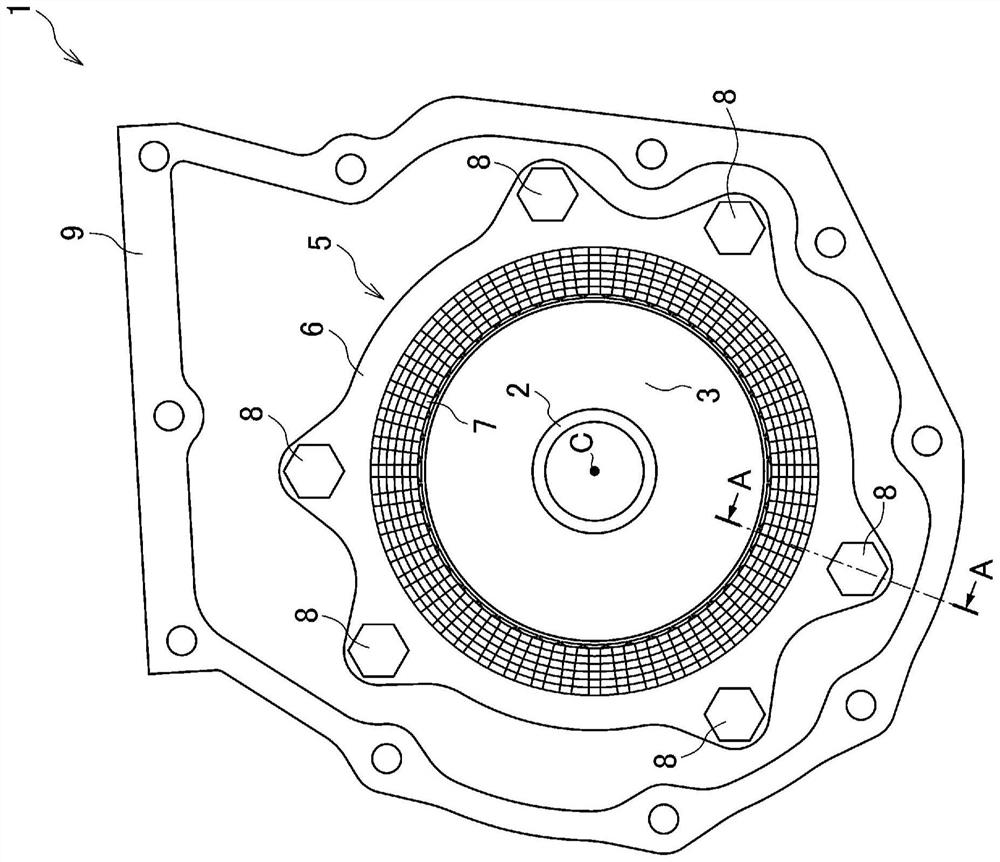

[0076] like figure 1 As shown, the rotating electrical machine 1 includes a rotor 3 , a stator 5 , and a housing 9 .

[0077] The rotor 3 has a rotor shaft 2 . There is a central axis C at the center of the rotor shaft 2 . The central axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com