Fragrant mask

A mask and fragrance technology, applied in the field of masks, can solve the problems of not being able to prepare masks, and achieve the effect of increasing the wearing experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

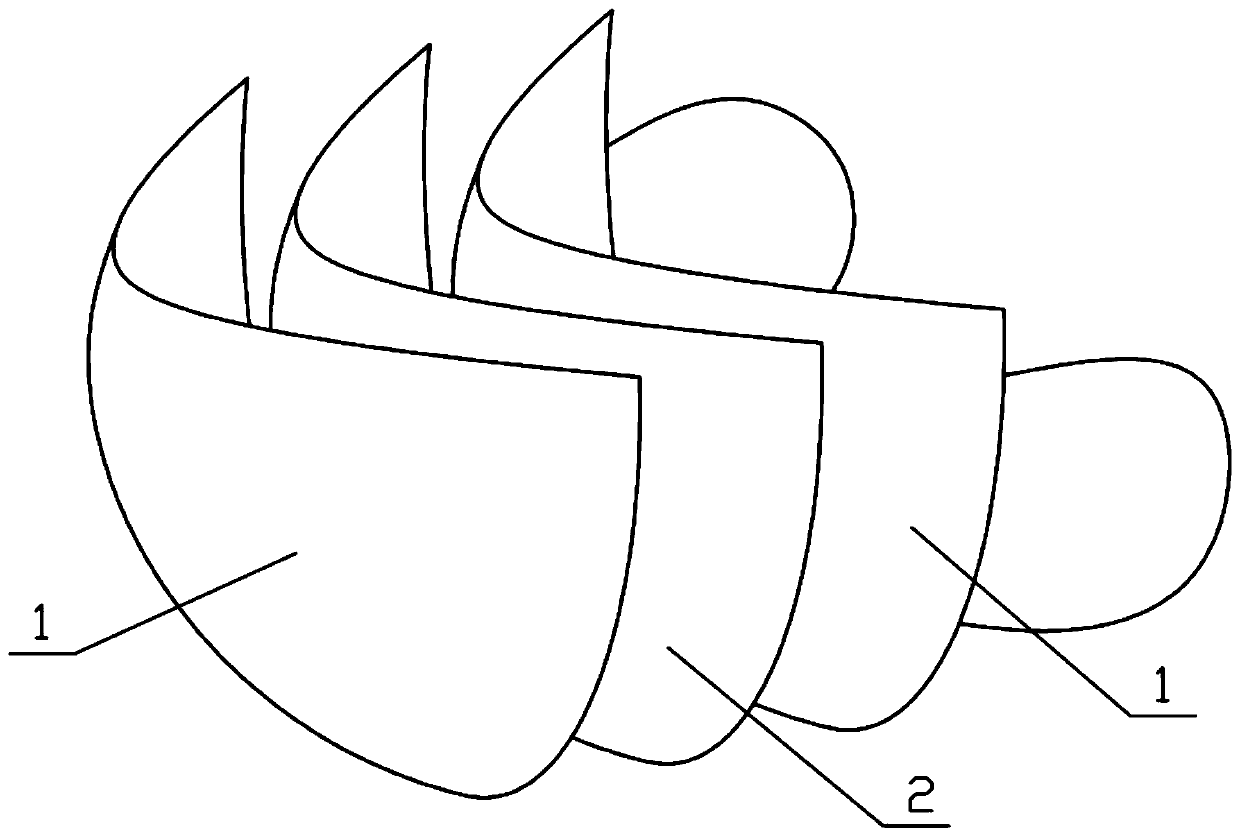

[0016] Combine below figure 1 Describe this embodiment, a mask with fragrance, including non-woven fabric layer 1 on both sides and melt-blown fabric layer 2 in the middle, the non-woven fabric layer 1 on both sides or one side of the non-woven fabric layer The outside of 1 is sprayed with liquid spray; the liquid with food flavor can be atomized and sprayed to the outside of the non-woven fabric layer 1 on both sides or one of the non-woven fabric layers 1 through an ultrasonic atomizer, so that the mask has fragrance Increase wearing experience; such as figure 1 As shown, spraying can be used on the outside of the nonwoven fabric layers 1 on both sides simultaneously, or one of the layers of nonwoven fabric layers 1 on both sides can be sprayed and sprayed, so that the mouth mask has fragrance.

specific Embodiment approach 2

[0018] Combine below figure 1 Illustrate this embodiment, this embodiment will further explain the first embodiment, the liquid spray is the spray produced by the atomized liquid of the ultrasonic atomizer; the ultrasonic atomizer can be the ultrasonic atomizer in the prior art, and the ultrasonic atomizer Spraying the sprayer onto the non-woven fabric layer for atomization can control the amount of spray to prevent affecting the effect of the melt-blown fabric.

specific Embodiment approach 3

[0020] Combine below figure 1 This embodiment will be described, and this embodiment will further describe the second embodiment, in which the liquid atomized by the ultrasonic atomizer is added with food flavor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com