Super-elastic high-resilience knitted fabric and preparation method thereof

A knitting fabric and recovery technology, applied in knitting, weft knitting, dyeing, etc., can solve problems such as hindering yoga enthusiasts from stretching postures, yoga enthusiasts are uncomfortable, hindering user experience, etc., and achieve excellent dyeability , excellent air permeability, good 3D effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A knitted fabric with superelasticity and high recovery, the raw materials of which are nylon yarn and spandex fiber.

[0036] Nylon yarn and spandex fiber are used as raw materials for the super-elastic and high-recovery knitted fabric described in this application. Because nylon yarn has excellent dyeability and spandex fiber has good elasticity, the dyeing of the fabric is uniform, not easy to fade, and has good elasticity. Good, good recovery, close-fitting, comfortable and beautiful when the user wears it.

[0037] Further, the fabric is a plated cotton wool structure.

[0038] Furthermore, when the fabric has a plated cotton wool structure, the nylon yarn is 20D-70D nylon filament, and the spandex fiber is 20D-70D spandex filament.

[0039] Furthermore, the draft ratio of the spandex fiber is 2.6-3.5.

[0040] Further, the super-elastic high-recovery knitted fabric described in this application is a 36G high-gauge plated cotton-wool structure.

[0041] Further,...

Embodiment 2

[0045] A knitted fabric with superelasticity and high recovery, the raw materials of which are nylon yarn and spandex fiber.

[0046] Nylon yarn and spandex fiber are used as raw materials for the super-elastic and high-recovery knitted fabric described in this application. Because nylon yarn has excellent dyeability and spandex fiber has good elasticity, the dyeing of the fabric is uniform, not easy to fade, and has good elasticity. Good, good recovery, close-fitting, comfortable and beautiful when the user wears it.

[0047] Further, the fabric is an air layer structure.

[0048] Furthermore, when the fabric has an air layer structure, the nylon yarn is 20D-70D nylon filament, and the spandex fiber is 20D-70D spandex filament.

[0049] Preferably, the proportion of spandex fiber in the fabric is 25%-35%.

[0050] Furthermore, the draft ratio of the spandex fiber is 2.6-3.5.

[0051] Further, the super-elastic high-recovery knitted fabric described in this application is a 3...

Embodiment 3

[0057] A method for preparing a superelastic high-recovery knitted fabric, the method is used to prepare the fabric described in the above-mentioned embodiment 1 or 2, and the preparation method comprises the steps of:

[0058] S1, yarn count preparation;

[0059] S2, fabric weaving;

[0060] S3, dyeing and finishing.

[0061] Further, the step S1, the yarn count preparation process includes: selecting nylon yarn and spandex fiber as the raw materials of the fabric.

[0062] Preferably, in the step S1, 20D-70D nylon filaments and 20D-70D spandex filaments are selected as raw materials to prepare fabrics with a plated cotton wool structure.

[0063] Preferably, in the step S1, 20D-70D nylon filaments and 20D-70D spandex filaments are selected as raw materials to prepare fabrics with an air layer structure.

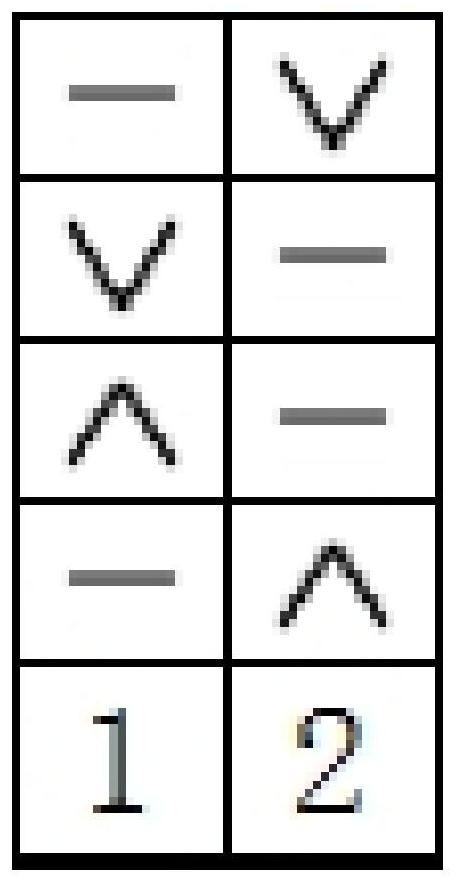

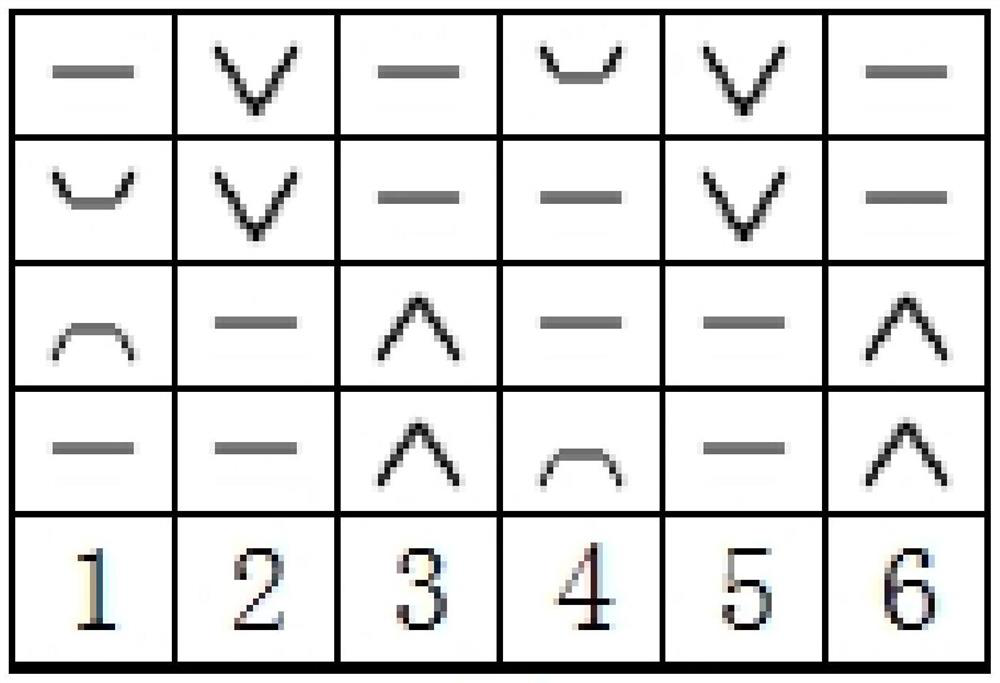

[0064] Further, in the step S2, according to figure 1 or figure 2 The triangular arrangement shown is for weaving of the fabric.

[0065] Further, said step S3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com