Flexible waterproof electric heating film and preparation method thereof

A flexible waterproof and electric heating film technology, which is applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating circuit diagrams, etc., to achieve good wearing experience and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

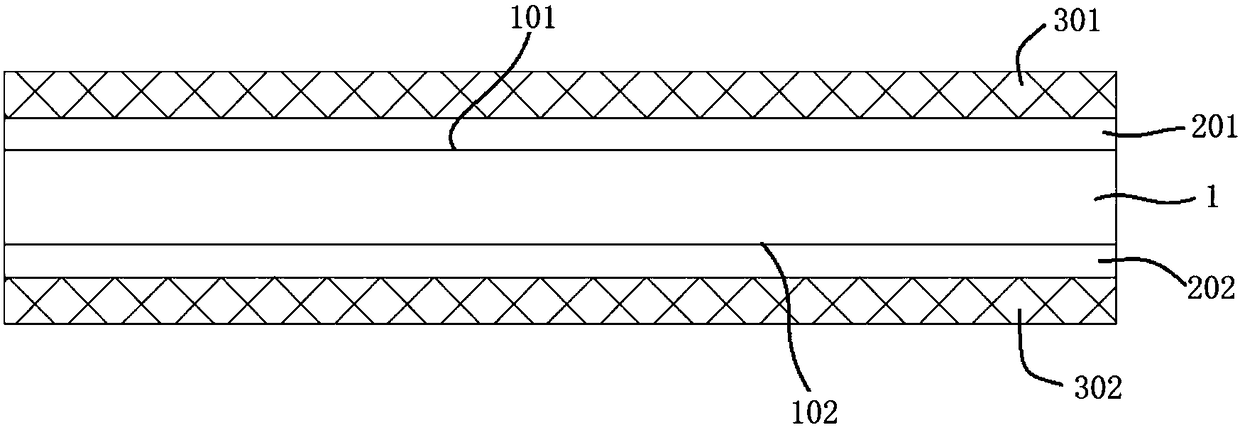

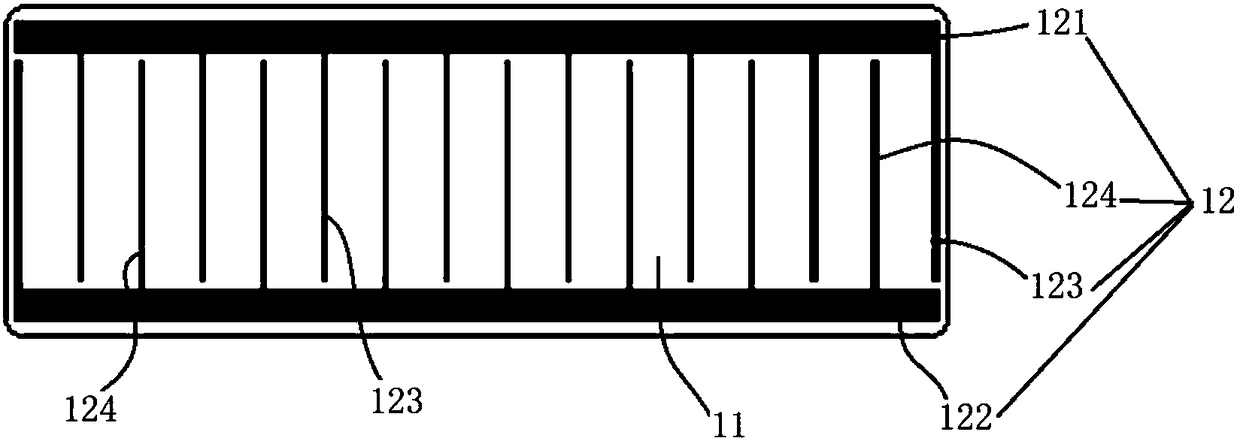

[0067] The top view of graphene heating film electrode structure and shape is as follows: figure 1 As shown, the electrode is an interdigitated electrode with equal spacing between branch electrodes, and the material is silver paste; the cross-sectional view of graphene heating film is shown in figure 2 As shown, the thicknesses of the waterproof cloth, the hot melt adhesive and the graphene layer are 160 μm, 50 μm, and 50 μm, respectively; the sheet resistance of the graphene layer is 130Ω / □. Bending the graphene heating film with a radius of curvature of 2 mm 1000 times increases the resistance by 1%, puts the graphene heating film in a washing machine for 1 hour, and the resistance increases by 0.5%.

Embodiment 2

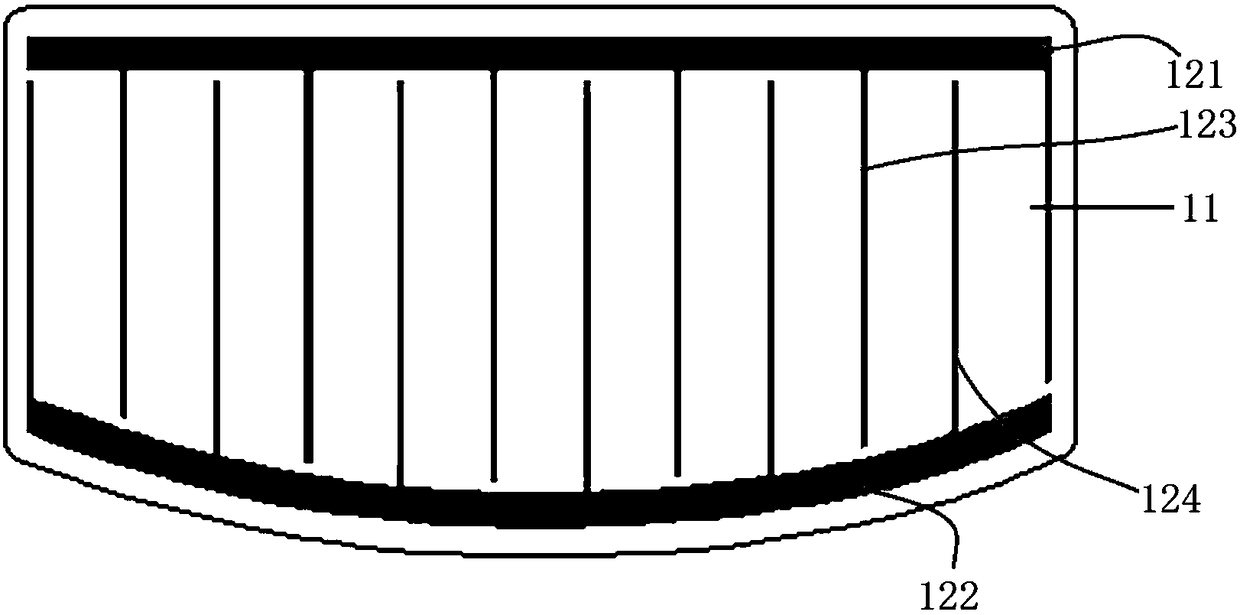

[0069] The top view of graphene heating film electrode structure and shape is as follows: image 3 As shown, the electrode is an interdigitated electrode with equal spacing between branch electrodes, and the material is copper paste; the cross-sectional view of the graphene heating film is shown in figure 2 As shown, the thicknesses of the waterproof cloth, the hot melt adhesive and the graphene layer are 150 μm, 40 μm, and 40 μm, respectively; the sheet resistance of the graphene layer is 150Ω / □. Bending the graphene heating film with a radius of curvature of 2mm 1000 times increases the resistance by 0.5%, puts the graphene heating film in a washing machine for 1 hour, and the resistance increases by 0.3%.

Embodiment 3

[0071] The top view of graphene heating film electrode structure and shape is as follows: Figure 4 As shown, the electrode is an interdigitated electrode with equal spacing between branch electrodes, and the material is silver paste; the cross-sectional view of graphene heating film is shown in figure 2 As shown, the thicknesses of the waterproof cloth, the hot melt adhesive and the graphene layer are 130 μm, 40 μm, and 40 μm, respectively; the sheet resistance of the graphene layer is 150Ω / □. Bending the graphene heating film with a radius of curvature of 2mm 1000 times increases the resistance by 0.5%, puts the graphene heating film in a washing machine for 1 hour, and the resistance increases by 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com