A device for sprinkling black iron sand on slices of purple clay teapot mud

A purple clay pot and slicing technology, which is applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as cumbersome locks and uneven thickness of purple sand pot mud pieces, and achieve the effect of preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

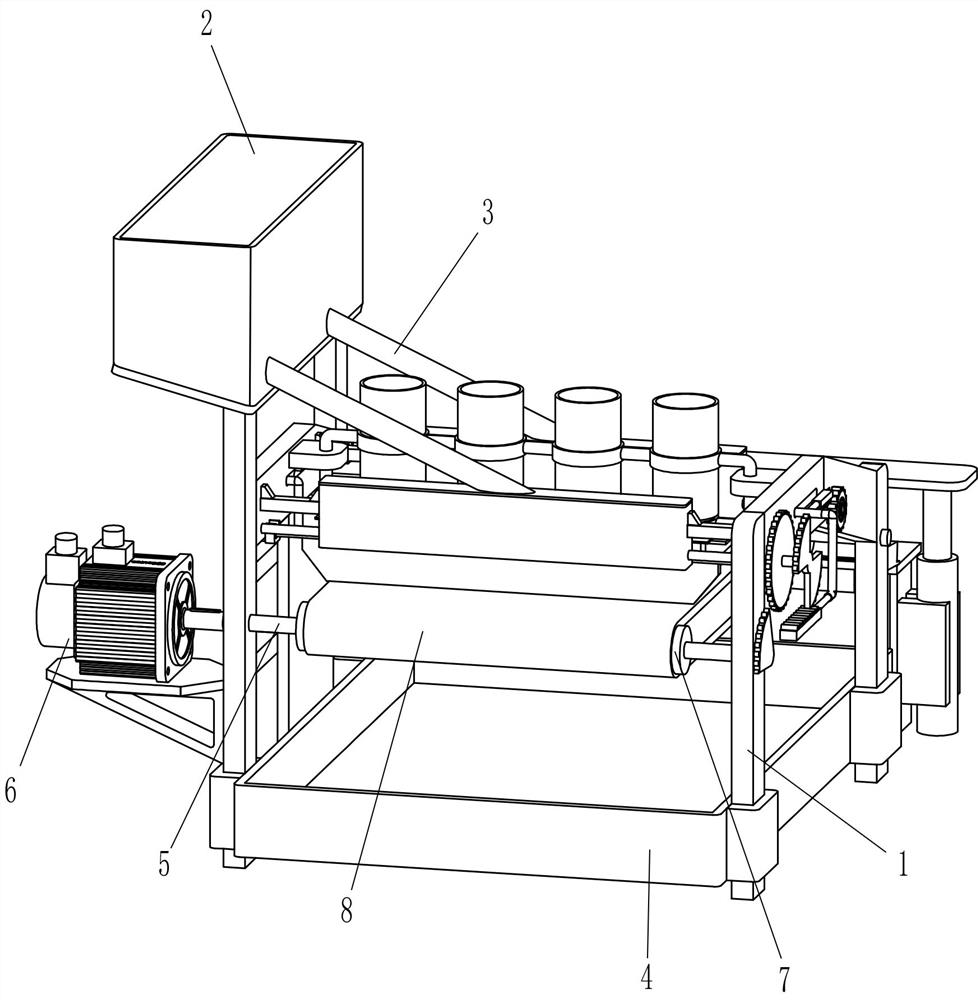

[0026]A teapot slice slice sprinkled black iron sand device, such asFigure 1-5As shown, including the rack 1, the hopper 2, the discharge tube 3, the collecting box 4, the transport mechanism, the sheet mechanism, the power mechanism, and the slice mechanism, and the upper left side of the rack 1 is welded. 2, the bottom of the hopper 2 is The tilt setting, the lower portion of the hopper 2 is symmetrically disposed, the left end of the discharge tube 3 is connected to the hopper 2, and the inner side of the frame 1 is connected to the collected box 4, and the rack 1 is provided. The front and rear two parts of the rack 1 are attached to the front and rear of the rack 1, and the sheet mechanism is located on both sides of the transport mechanism, and the right wall of the frame 1 has a power mechanism, and the middle portion of the rack 1 is mounted with a slice, slice. The mechanism is located above the middle of the transport mechanism, and the transmission mechanism is driven by ...

Embodiment 2

[0029]A teapot slice slice sprinkled black iron sand device, such asFigure 1-5As shown, the transport mechanism includes a first rotor 5, a reduction motor 6, a drum 7, and a conveying belt 8. The front and rear sides of the frame 1 are connected to the first rotor 5, and the first turn on both sides of the front and rear The rod 5 is fixed to the roller 7, and the front and rear side drums 7 are provided with a conveyed belt 8, and the front side of the frame 1 is fixedly mounted by a trigger 6, and the speed reduction motor 6 is located at the front side of the hopper 2. Next, the right end of the output shaft of the reducing motor 6 is fixed to the left end of the front side first traveler 5.

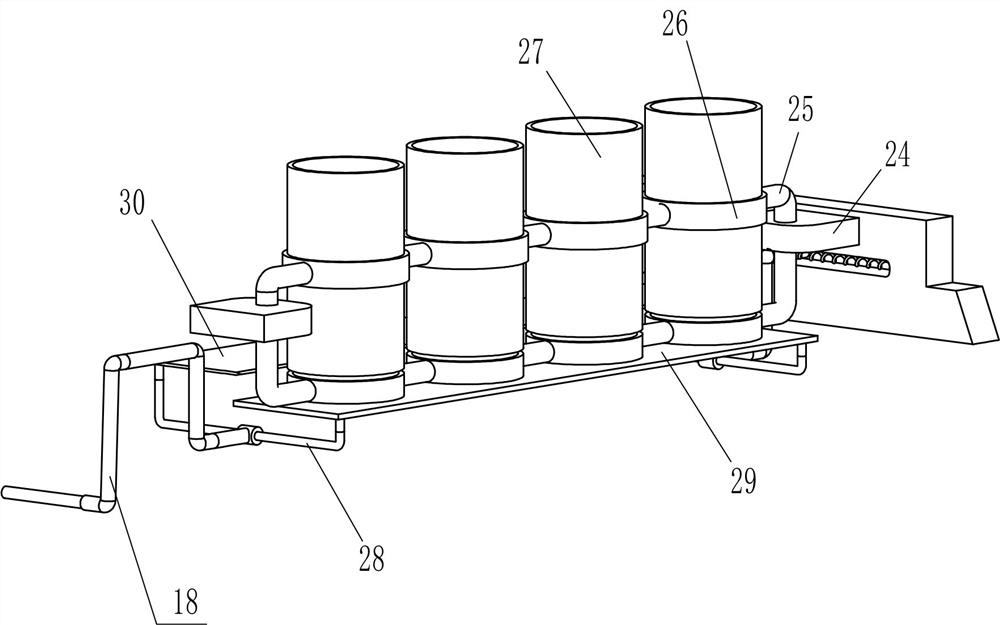

[0030]The sheet metal includes a fixed block 9, a casing 10, a second rotor 11, a torsion spring (1101) and the columnar body 12, and the front and soone of the front and rear of the frame 1 are fixed, and the fixed block 9 is fixedly provided with a fixed block 9, the front side. A casing 10...

Embodiment 3

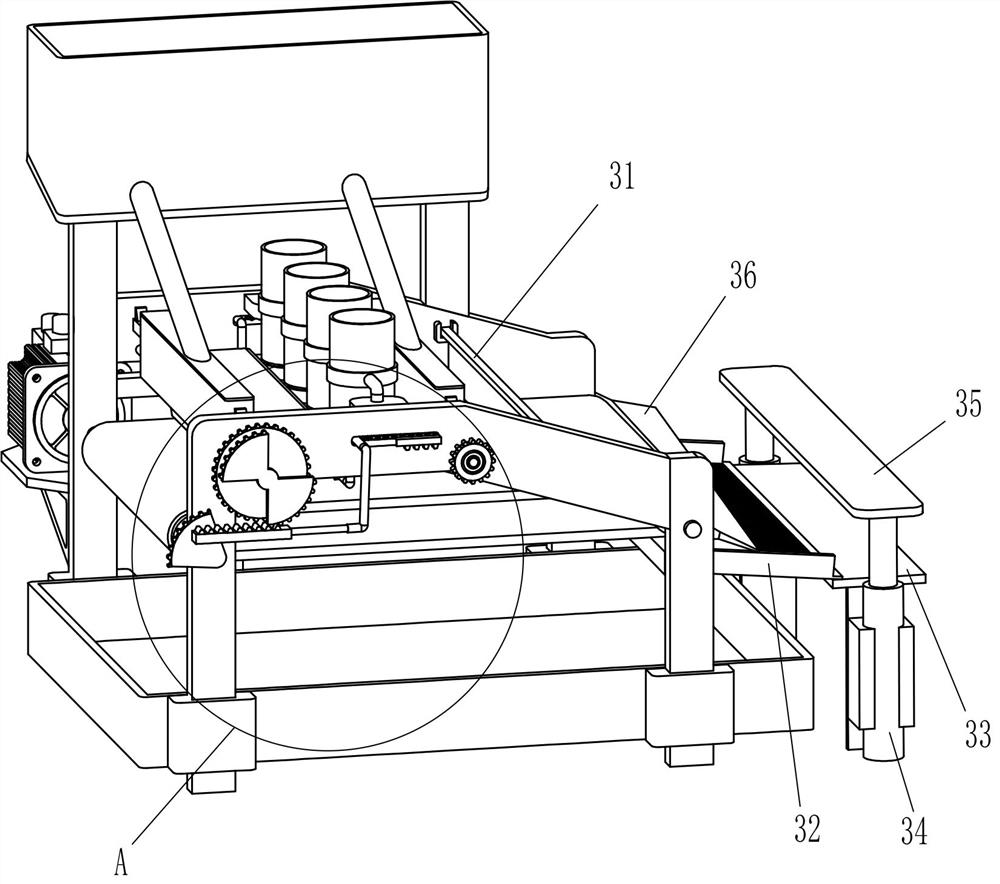

[0038]A teapot slice slice sprinkled black iron sand device, such asFigure 5 As shown, it includes a cross-board 31 having a cross-rear side of the frame 1, and the lateral plate 31 is fixedly mounted, the lateral plate 31 on the front side is located on the rear side of the front side, and the rear side cross plate 31 is located behind the rear side. The rear side of the sheet metal, the height of the bottom wall of the rear side leverangulation 31 is higher than the height of the bottom wall of the front side.

[0039]It also includes a mesh plate 32, an extrudate table 33, a telescopic rod 34, a pressure plate 35, and a sloping plate 36, and a sheet 32 having a retaining plate 32, and the mesh plate 32 is inclined, and the rear side of the mesh plate 32 is connected. The extruded table 33, the left and right sides of the extruded table 33 is slidably disposed, and the top end of the telescoping rod 34 is attached, and the pressure plate 35 is located directly above the extrudation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com