Automatic feeding device for pipe baking

A technology of automatic feeding and pipe fittings, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as unevenness, easy ink baking on the surface of the bottle body, etc., to achieve simple structure and avoid uneven baking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

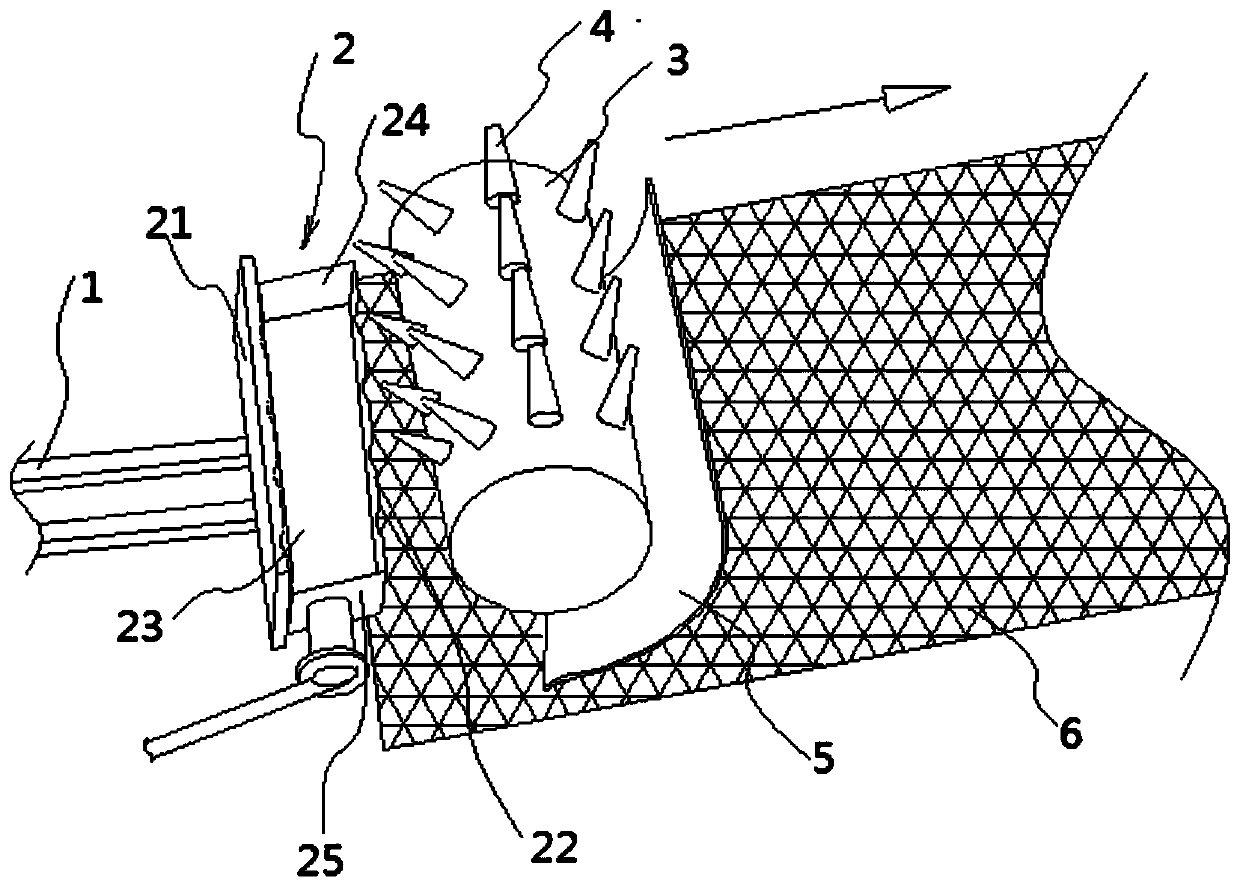

[0012] like figure 1 As shown, an automatic feeding device for pipe fittings baking includes a translation track, a moving seat, a splicing roller, a push rod, a conveying screen and an arc-shaped baffle, and the moving seat includes a front baffle, a rear baffle, a bottom plate, The first side plate and the second side plate, the front baffle and the rear baffle are relatively arranged on the bottom plate, and the back baffle is made of hard plastic, the height of the front baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com