Anti-skew-pulling and slanting-lifting device during driving and control circuit

A control circuit and inclined hoisting technology, applied in the directions of travel mechanism, transportation and packaging, load hanging components, etc., can solve problems such as damage to the rope arrangement, jamming, damage to the electric hoist, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

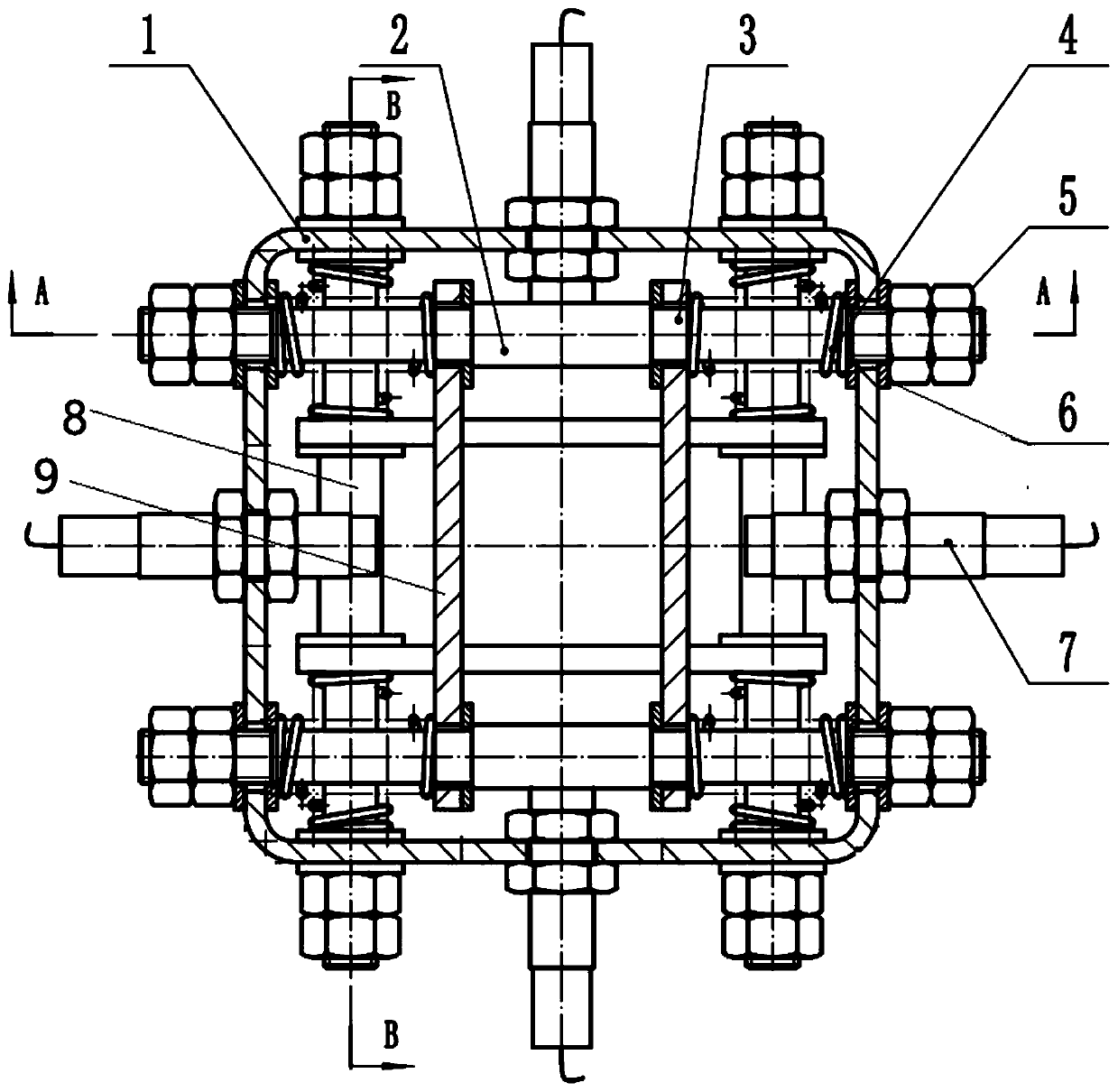

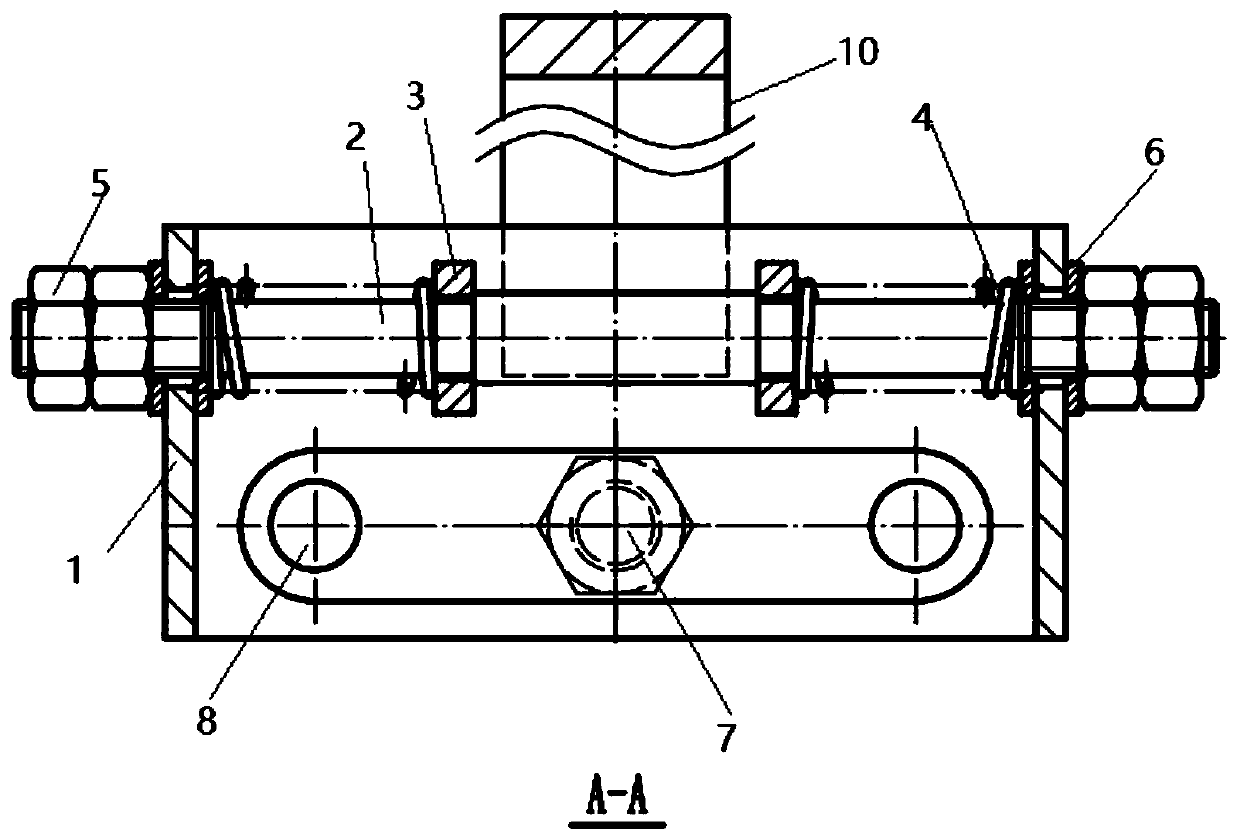

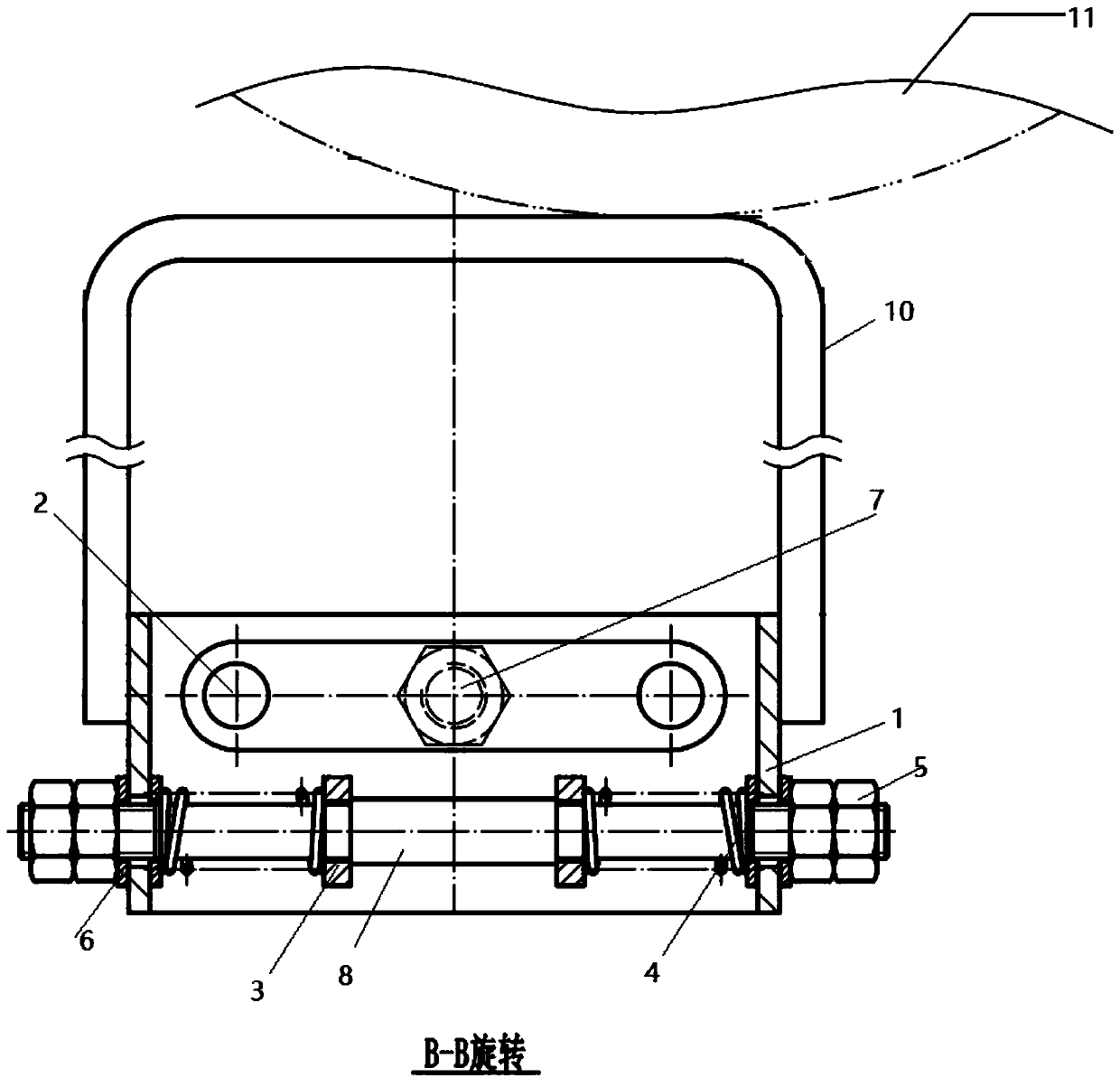

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0023] Such as Figures 1 to 5 As shown, the present embodiment provides a driving anti-skewing tilting device, including a frame body, a set of longitudinal shafts and a set of transverse shafts perpendicular to the longitudinal shafts are fixedly installed on the frame body, and each set of Baffles are movably installed on the longitudinal axis and the transverse axis, and compression springs are installed on the outside of the baffle on the longitudinal axis and the transverse axis of each group, and each of the four walls of the frame body is equipped with a spring controlled by a control circuit. Proximity switches, the heads of each of the proximity switches are respectively aligned with the centers of the four baffles.

[0024] Further, both the transverse axis and the longitudinal axis are fixed on the frame body through hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com