Unmanned grab bucket travelling crane steel wire rope deviation rectifying device

A technology of deviation correction device and wire rope, which is applied in the direction of safety device, transportation and packaging, and load hanging components, etc., can solve the problems of tilting the grab bucket left and right and reducing work efficiency, so as to prevent crooked pulling and hanging, improve work efficiency, and reduce the price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

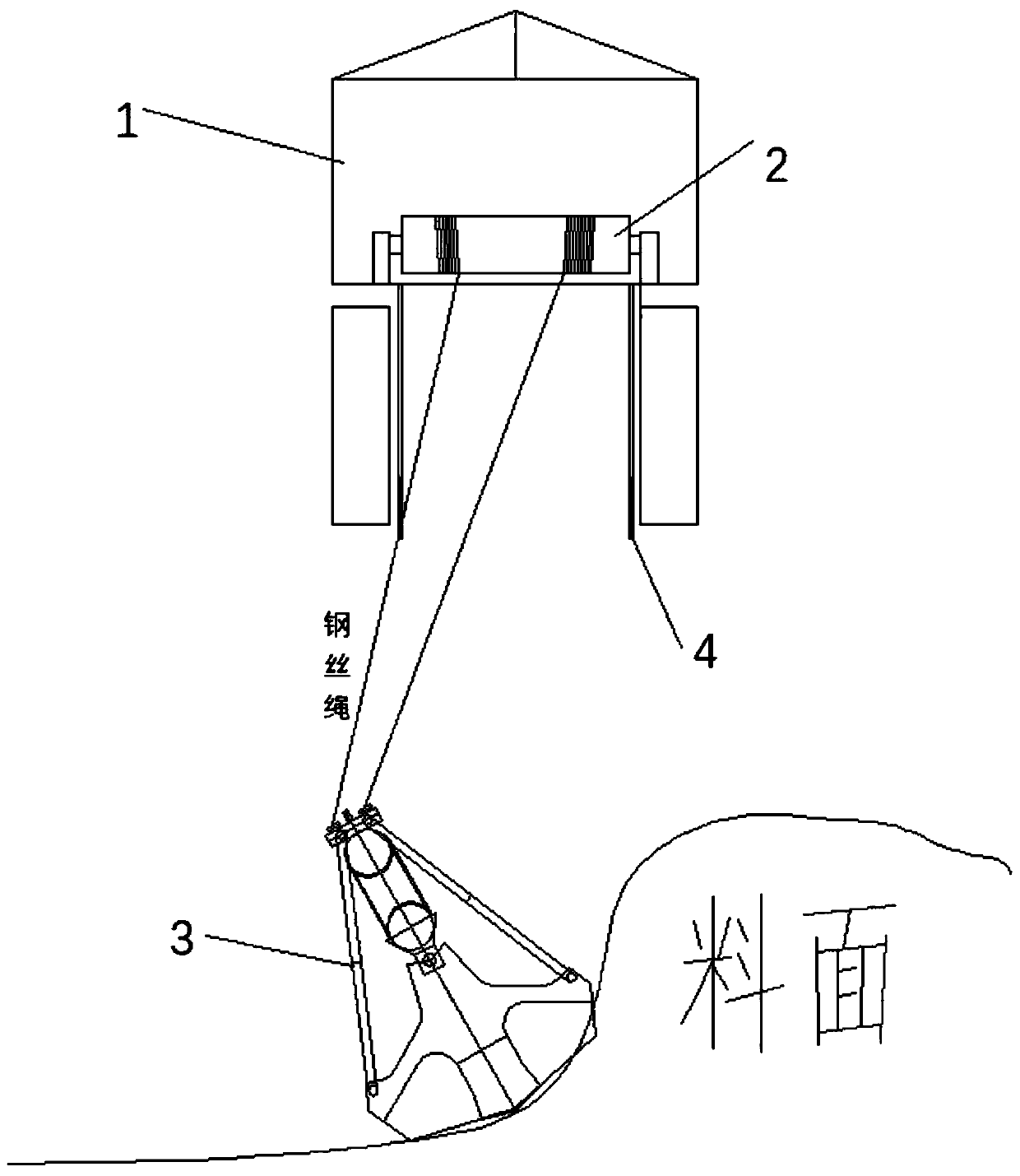

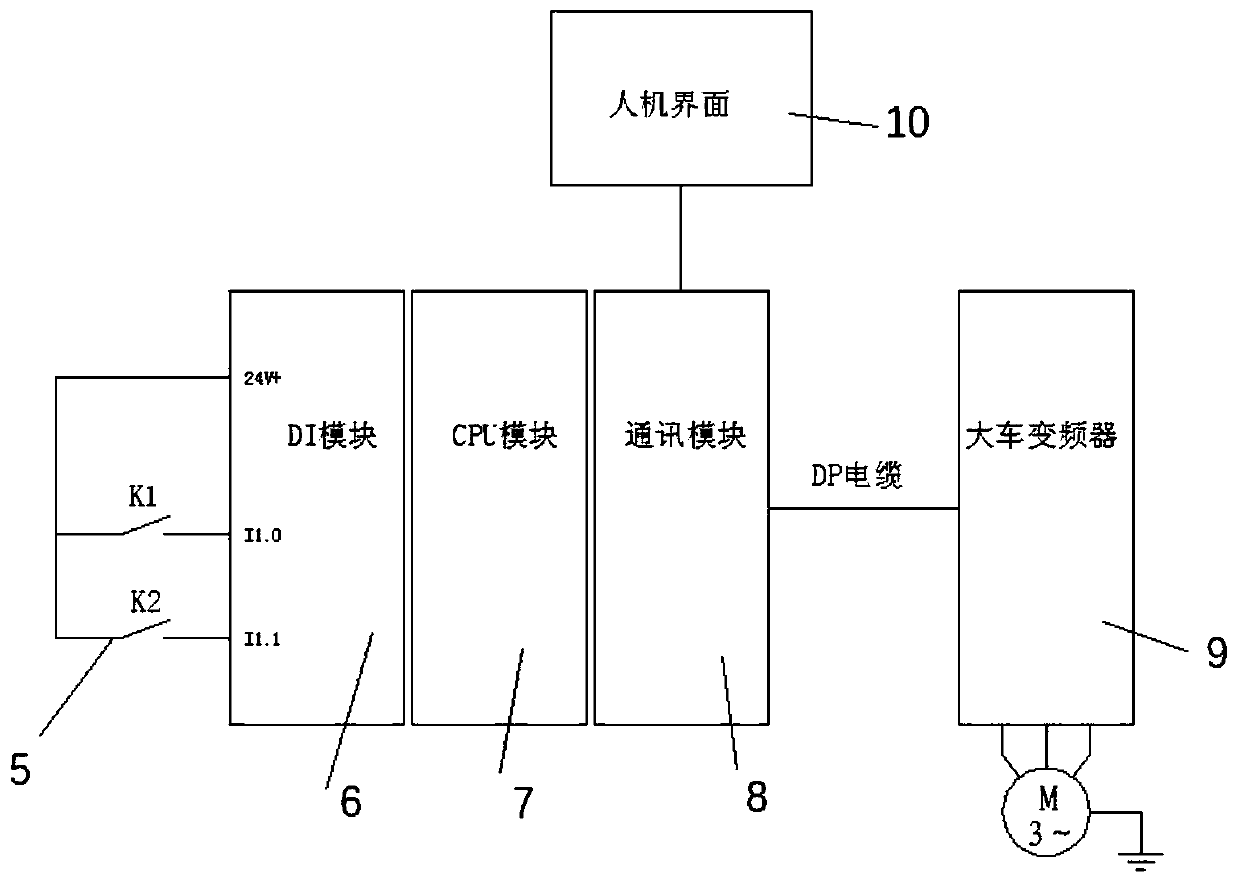

[0028] The embodiment of the present invention provides an unmanned grab driving wire rope deviation correction device, please refer to figure 1 , an unmanned grab driving steel wire rope deviation correction device of the present invention is applied to an unmanned grab driving. The unmanned grab driving includes a trolley 1, a wire rope drum 2, and a grab bucket 3. On the trolley 1, a wire rope is wound on its outer surface, the outer end of the wire rope is connected to the grab bucket 4, and the grab bucket 4 is located below the wire rope drum 2. The device includes: Equipment 4, intermediate relay 5, digital input equipment 6, CPU equipment 7, communication equipment 8, frequency converter 9.

[0029] The detection device 4 is connected with the wire rope drum 2, and generates a signal when in contact with the wire rope.

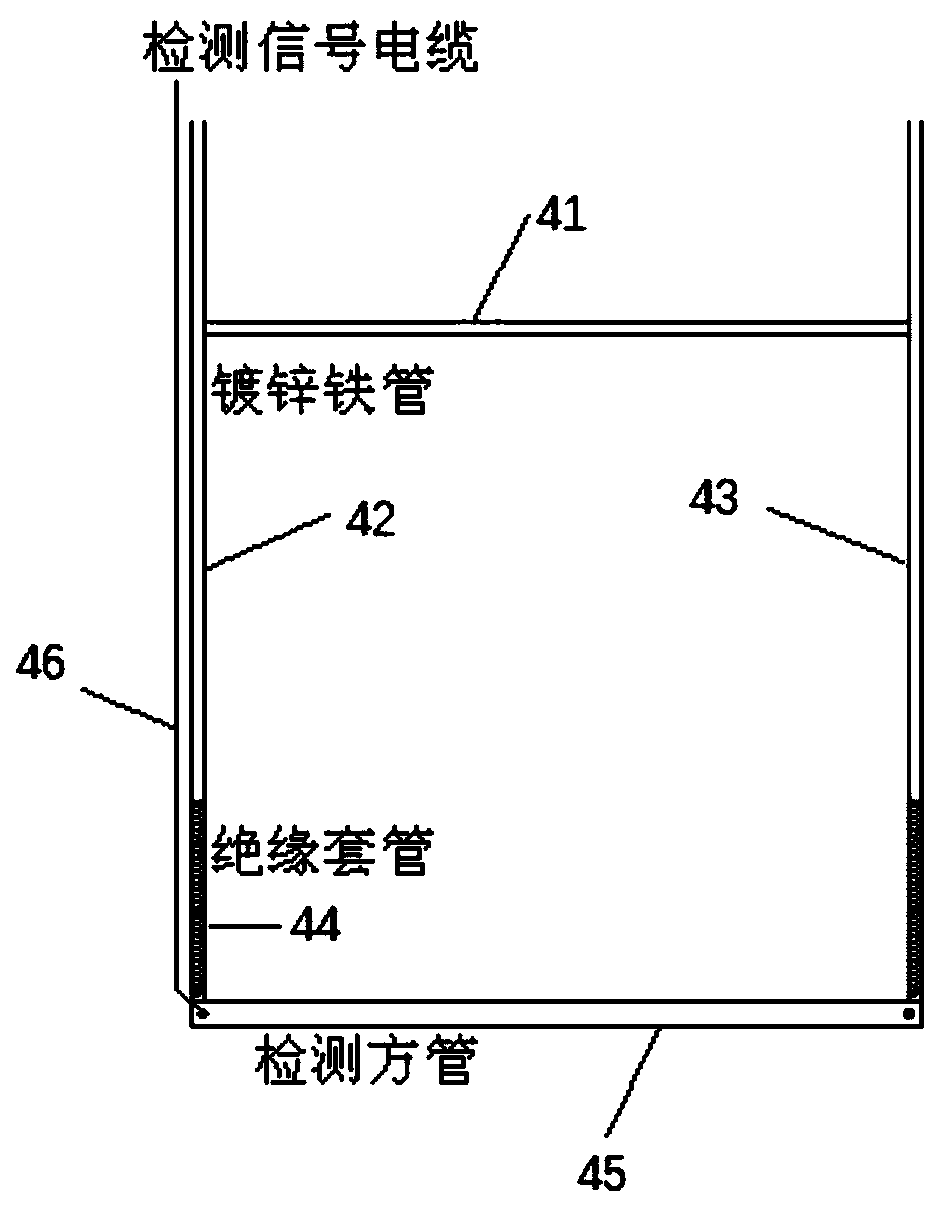

[0030] Further, the detection device 4 includes: a galvanized iron pipe connected to the wire rope drum 2, wherein the galvanized iron pipe includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com