Construction method for installing and dismantling coke jar cover from drill tower of dry quenched coke hoist by using temporary trolley

A construction method and technology for coke can lids, which are applied in the cooling of coke, coke oven, petroleum industry, etc., can solve the problems of high labor intensity, long construction time, low maintenance efficiency, etc., and achieve low labor intensity, short construction period, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] See Figure 1-3 , A construction method for installing and removing the coke tank cover from the CDQ hoist frame by using a temporary trolley, which includes the following steps:

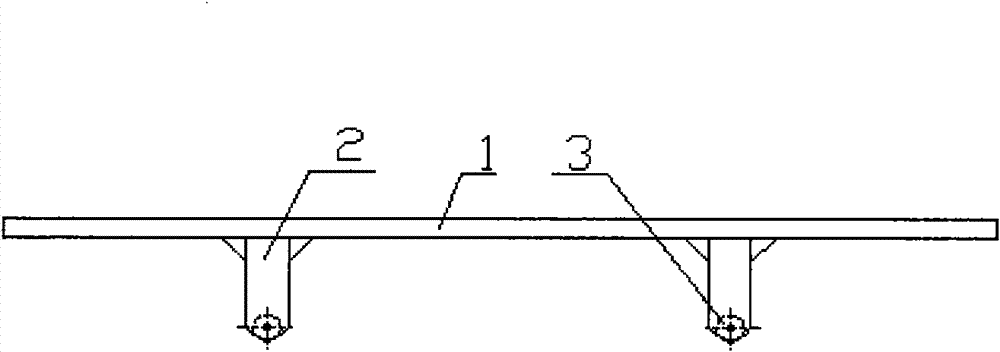

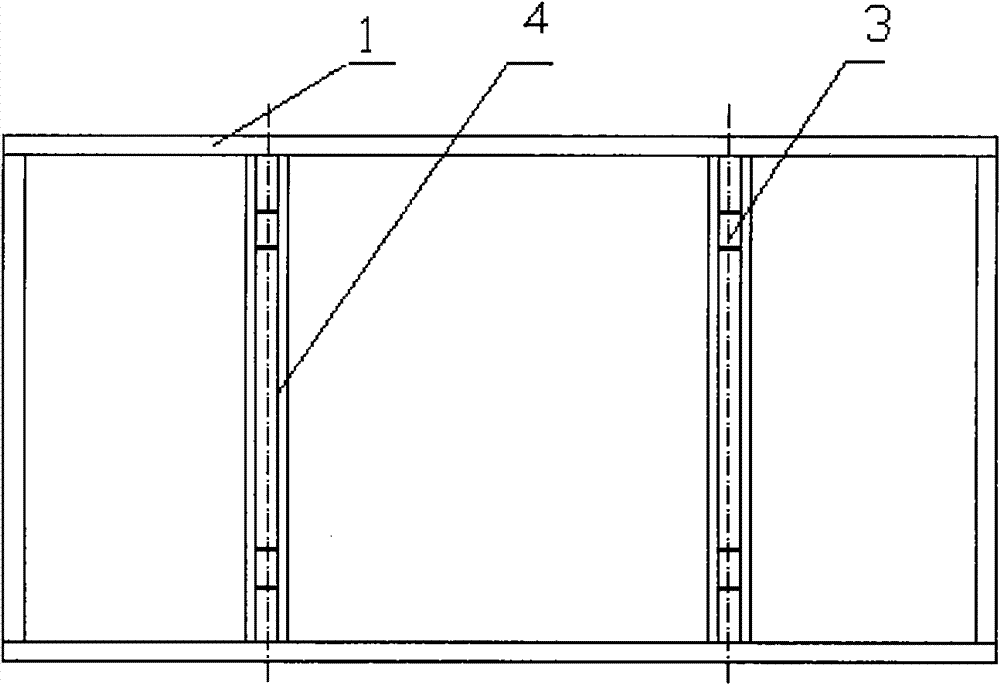

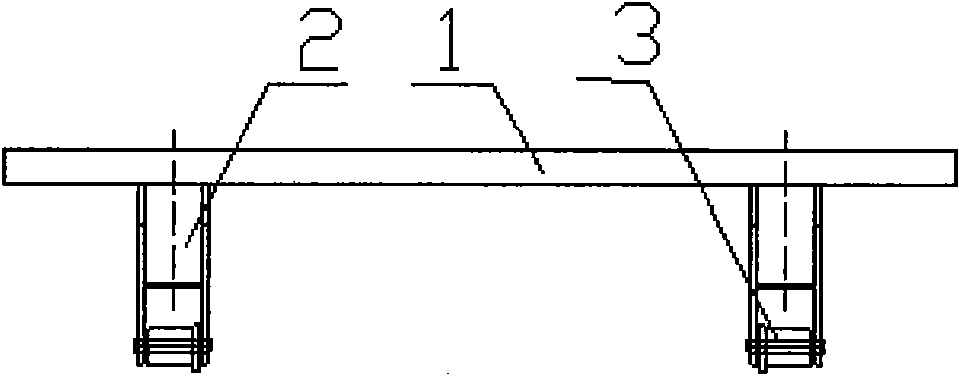

[0025] (a) Pre-make a temporary trolley with the same span as the coke truck track, and place the temporary trolley on the traction platform or the coke tank inspection platform. The temporary trolley includes a frame 1 with a horizontal support frame inside the frame 4. The number of horizontal support frames can be set according to needs. Support feet 2 are symmetrically provided on both sides of the lower part of the frame, and there are at least two support feet on each side, and walking wheels 3 are provided under each support foot;

[0026] (b) Transport the temporary trolley to the coke-transporting vehicle track by using the traction mechanism, the pulling platform and the coke transporter at the coke tank maintenance platform;

[0027] (c) When installing the coke tank cover, first use a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com