Door with buffer effect

A door body and shaft technology, applied in the field of doors with a buffer effect, can solve the problems of wear or tear of rubber strips, inability to achieve buffer silence, damage to the door body structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

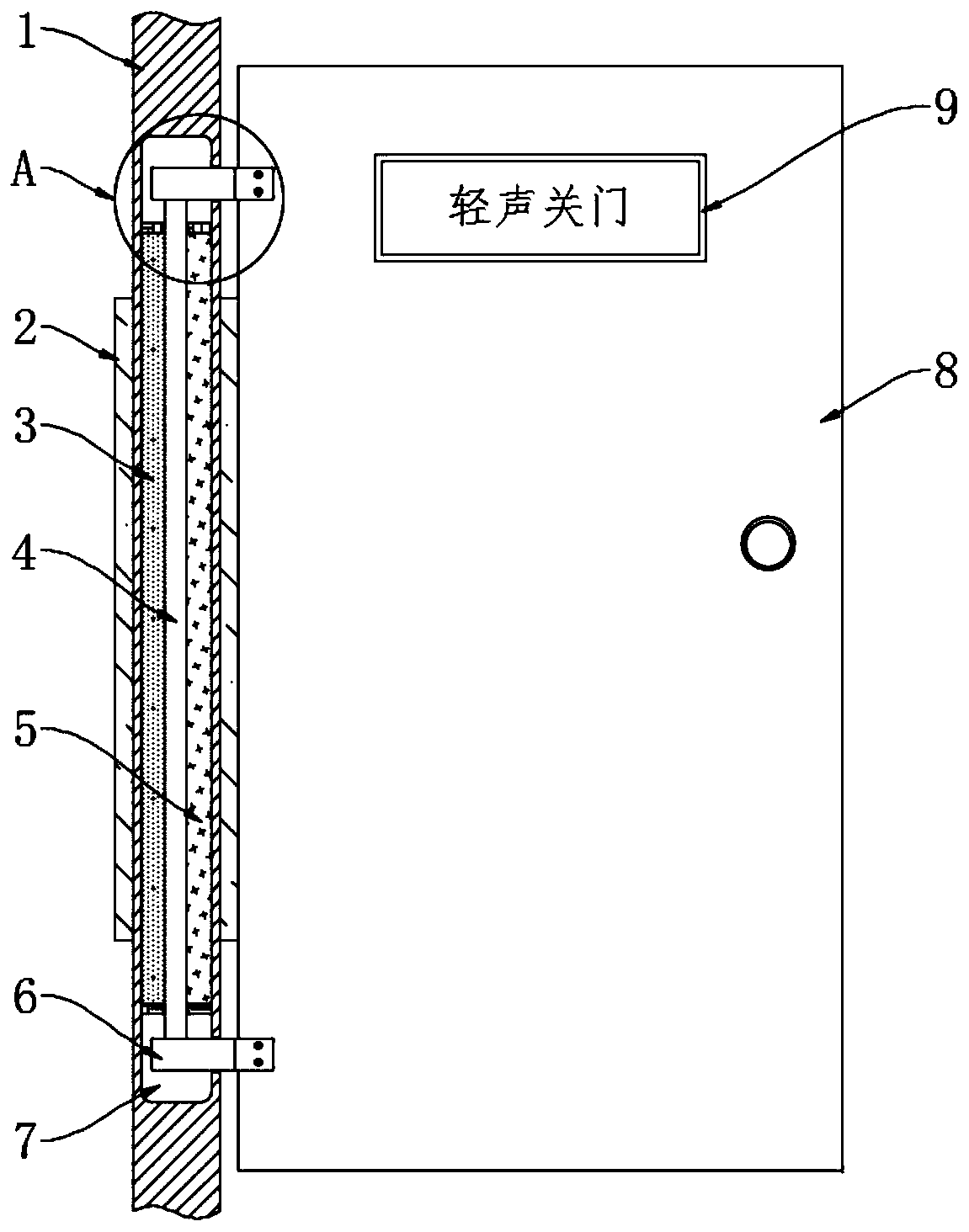

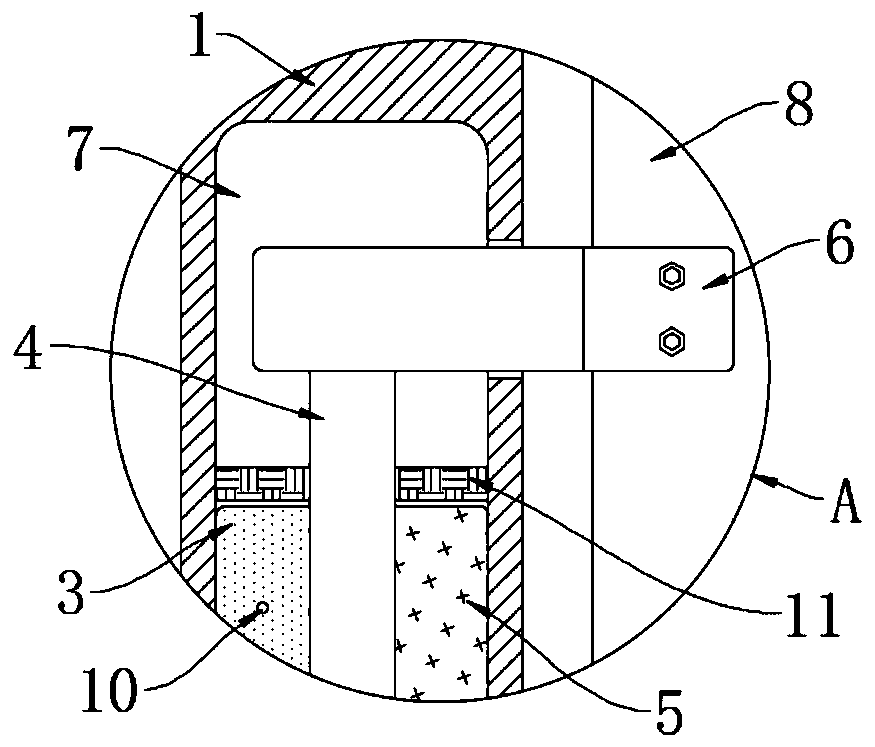

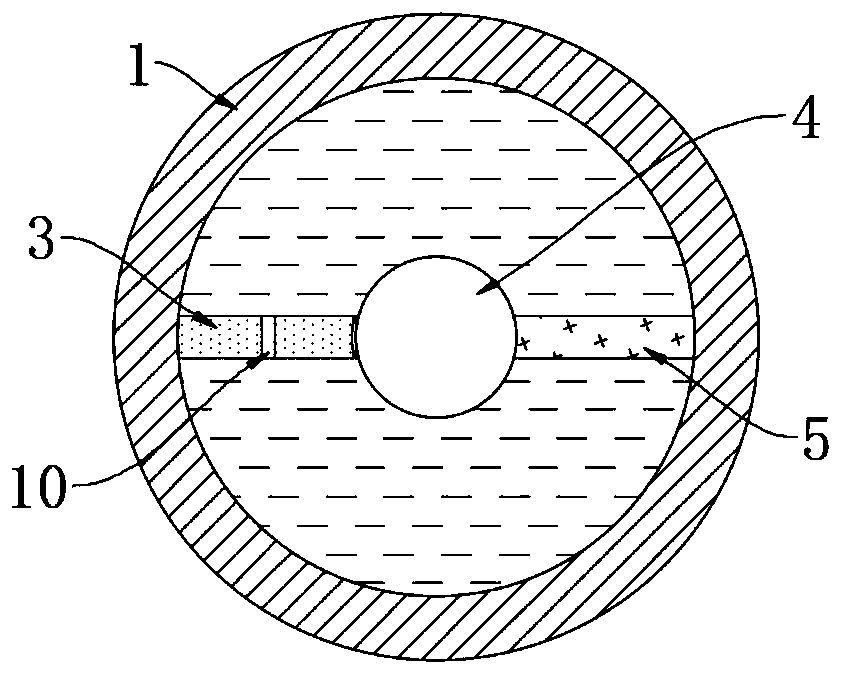

[0028] refer to Figure 1-3 , a door with a buffer effect, including a rotating shaft 1 and a door body 8, the door body 8 is rotationally connected with the rotating shaft 1 through a shaft sleeve 2, and the shaft sleeve not only plays the role of connecting the door body 8 and the rotating shaft 1, but also supports the door The role of the body 1, the rotating shaft 1 is provided with a hollow cavity 7, the upper and lower ends of the hollow cavity 7 are symmetrically sealed with a sealing ring 11, the center of the two sealing rings 11 is installed with a rotating rod 4, and the rotating rod 4 and The two sealing rings 11 are sealed and slidingly connected, two semi-arc grooves are symmetrically opened on the rotating shaft 1, and connecting rods 6 are fixedly connected to both ends of the rotating rod 4, and each connecting rod 6 is far away from the rotating rod 4 One end of each is fixedly connected with the door body 8 through a semi-arc groove;

[0029] A fixed plate...

Embodiment 2

[0035] refer to Figure 4-6 , the present embodiment differs from Embodiment 1 in that: the identification plate 9 includes a housing, a see-through window 901 and a plate 902, a transparent capsule 15 is thermally fused in the housing, and the transparent capsule 15 is located between the plate 902 and the housing Between the inner side walls, the transparent capsule 15 can be regarded as the background of the plate 902 , and the color change of the transparent capsule 15 can be seen through the plate 902 .

[0036] In this embodiment, the rotating rod 4 and the connecting rod 6 are provided with a thin tube 14, the thin tube 14 includes a horizontal end and a vertical end, the horizontal end of the thin tube 14 communicates with the transparent capsule 15, and the thin tube 14 vertical end The end nozzle runs through the side wall of the rotary rod 4 and extends to the outside of the rotary rod 4, and a pressure valve 13 is installed at the vertical end of the thin tube 14. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com