Display screen splicing mechanism

A display screen and hinged technology, which is applied in the direction of supporting machines, mechanical equipment, machine tables/brackets, etc., can solve problems such as inconvenient adjustment, dislocation of display screens, cumbersome adjustments, etc., and achieve rapid changes, tidy splicing and installation, and rational use of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

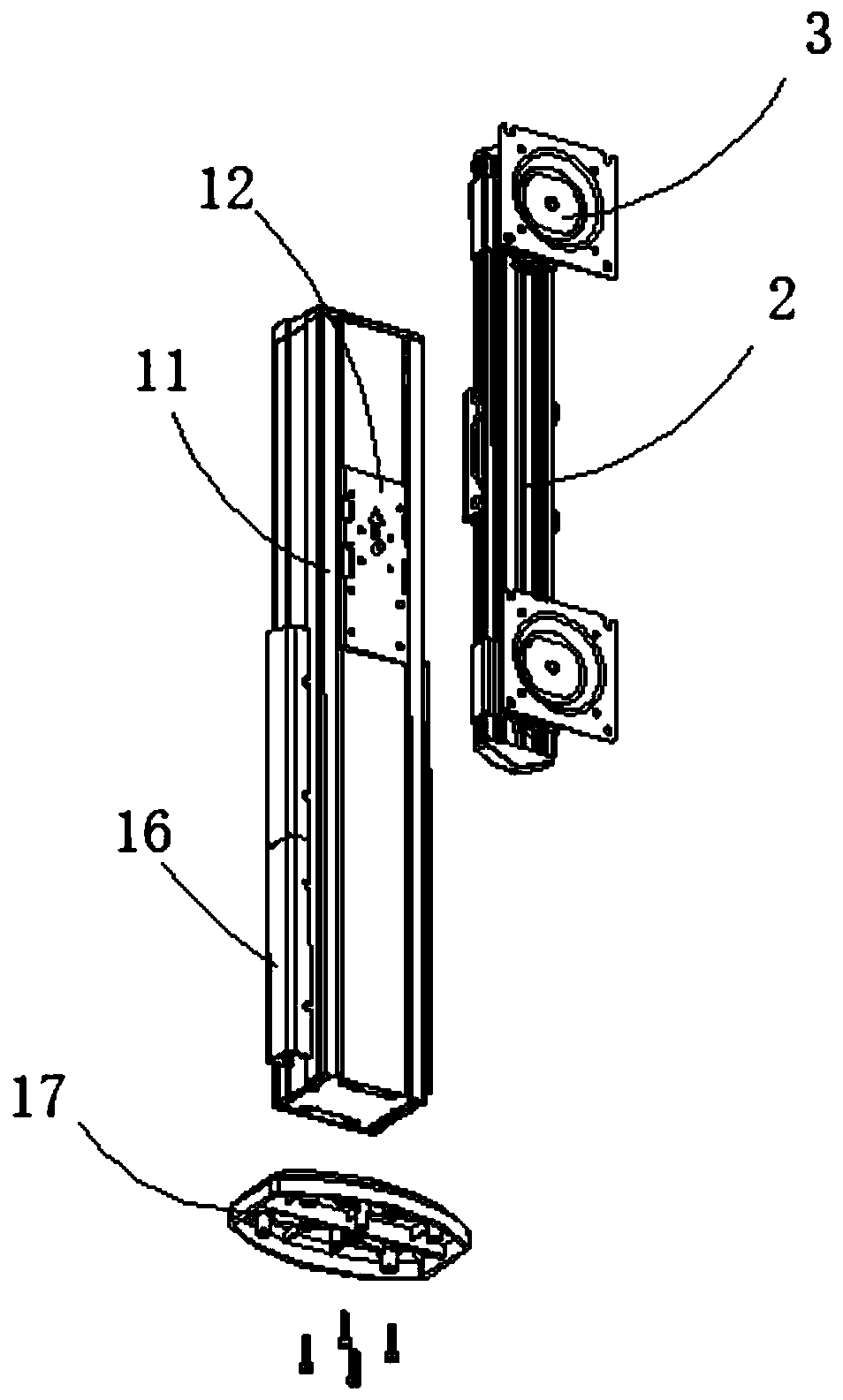

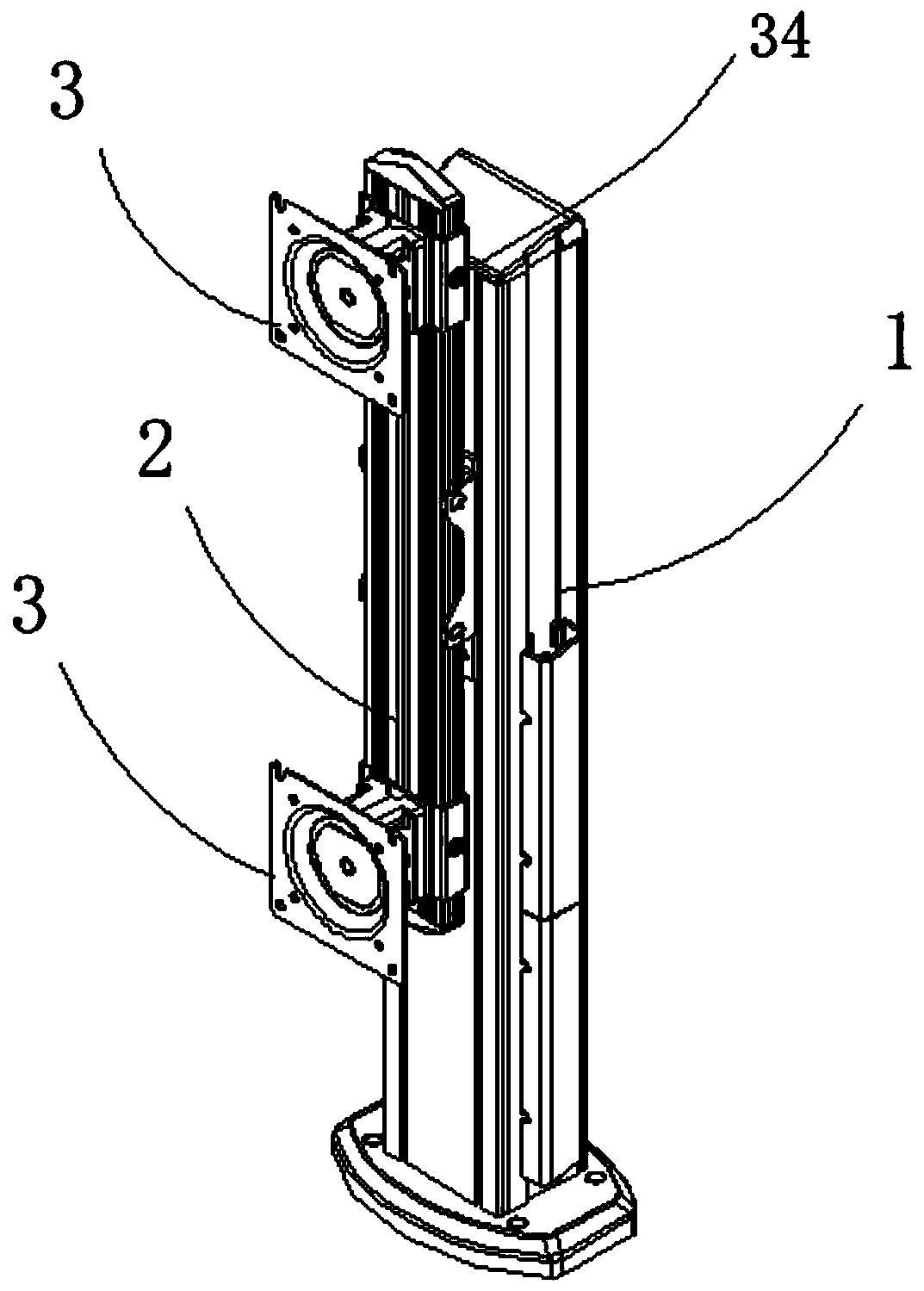

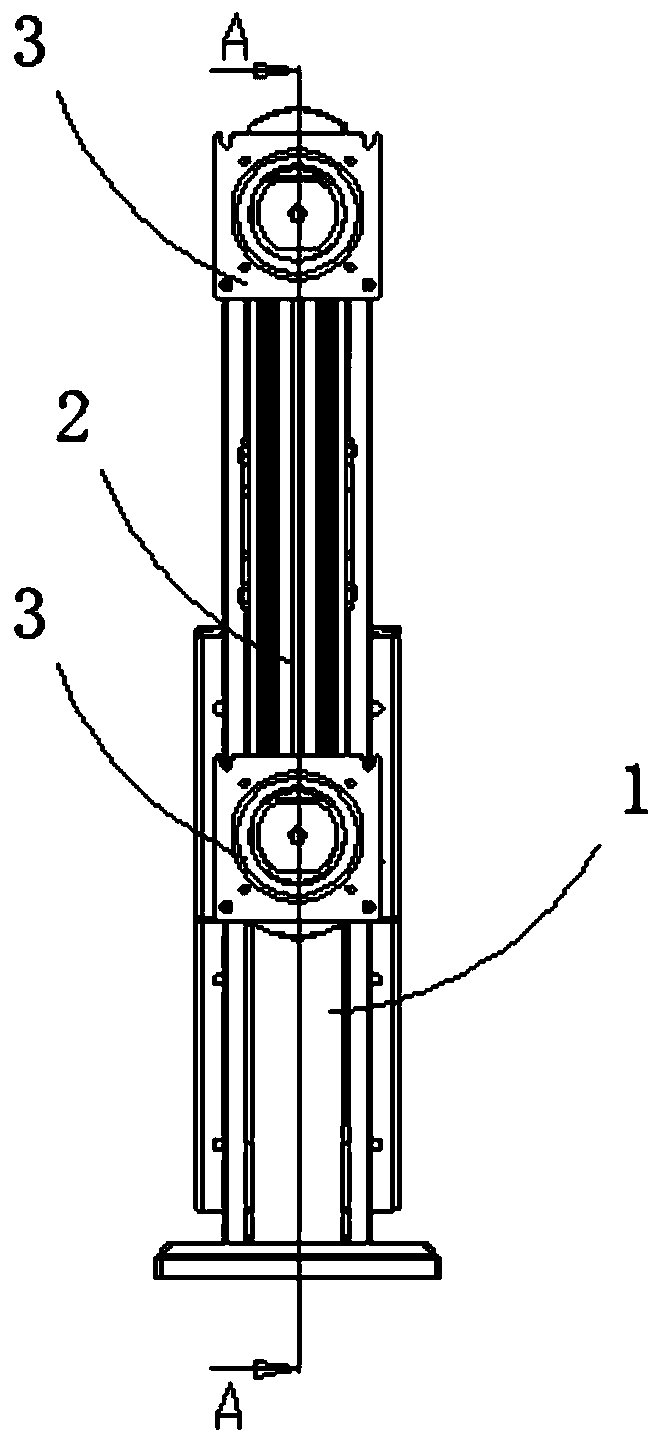

[0029] Embodiment: A display screen splicing mechanism, including a fixed frame 1, a horizontal rail assembly 2, and a display screen installation assembly 3, on which a display screen 4 can be fixedly installed, and at least two display screen installation assemblies 3 are connected to each other They are installed at intervals on the cross rail assembly 2, and the cross rail assembly 2 can be installed on the fixed frame 1 to adjust the angle in the installation plane.

[0030] When in use, the fixed frame 1 is installed on the desktop or the wall, the display screen 4 is installed on the display screen installation assembly 3, and the display screen can be adjusted in different directions by adjusting the angle of the horizontal rail assembly 2 in the vertical plane. Arrangement, if the horizontal rail assembly 2 is placed horizontally, the display screens 4 are arranged horizontally, and the horizontal rail assembly 2 is extended vertically, then the display screens 4 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com