Novel automobile shock absorber testing device

A technology of automobile shock absorber and testing device, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., which can solve inconvenient fixed work, inconvenient detection of shock absorber corrosion resistance, inconvenient imitation Problems such as shock absorption effect, to achieve the effect of convenient detection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the drawings:

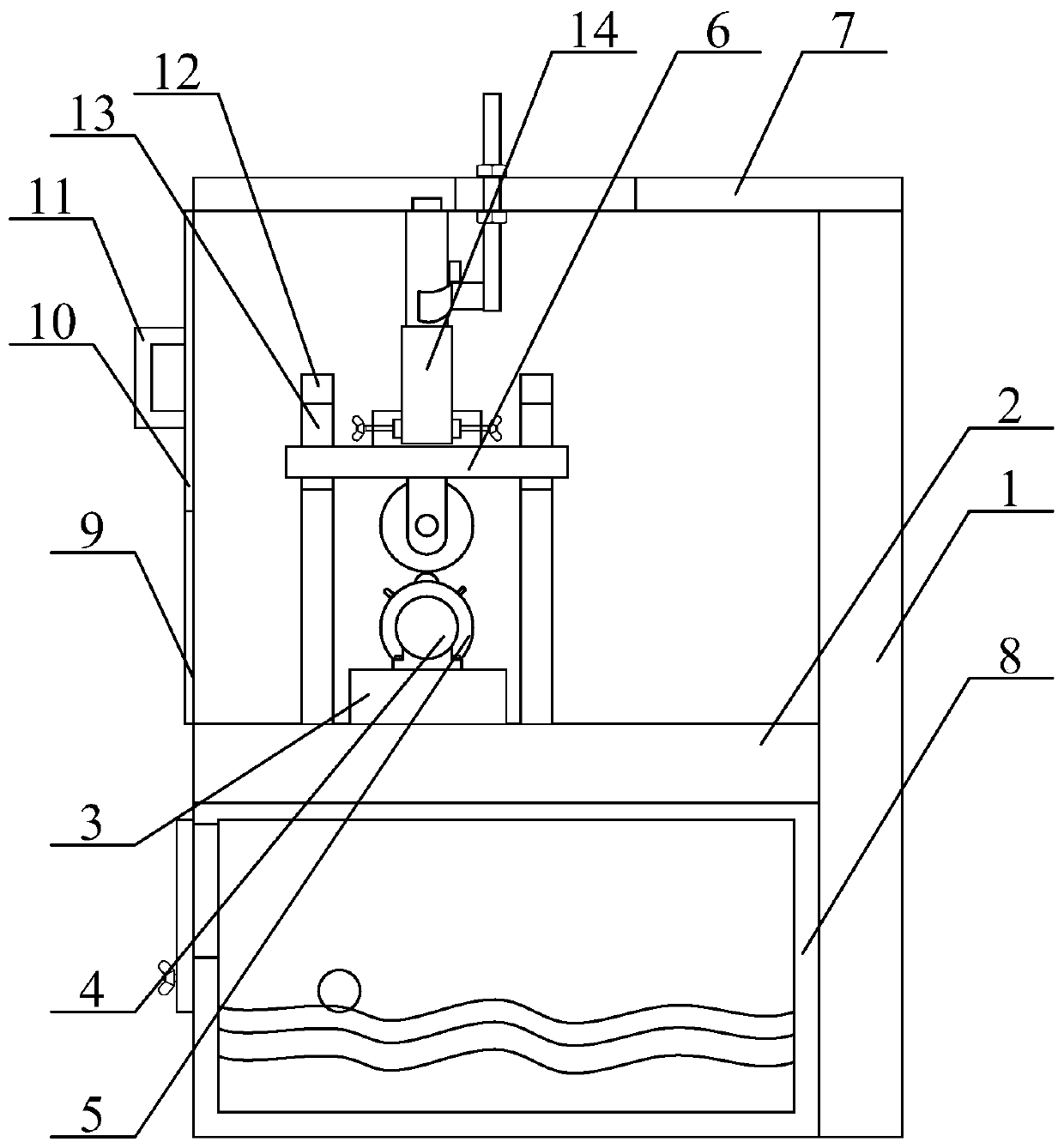

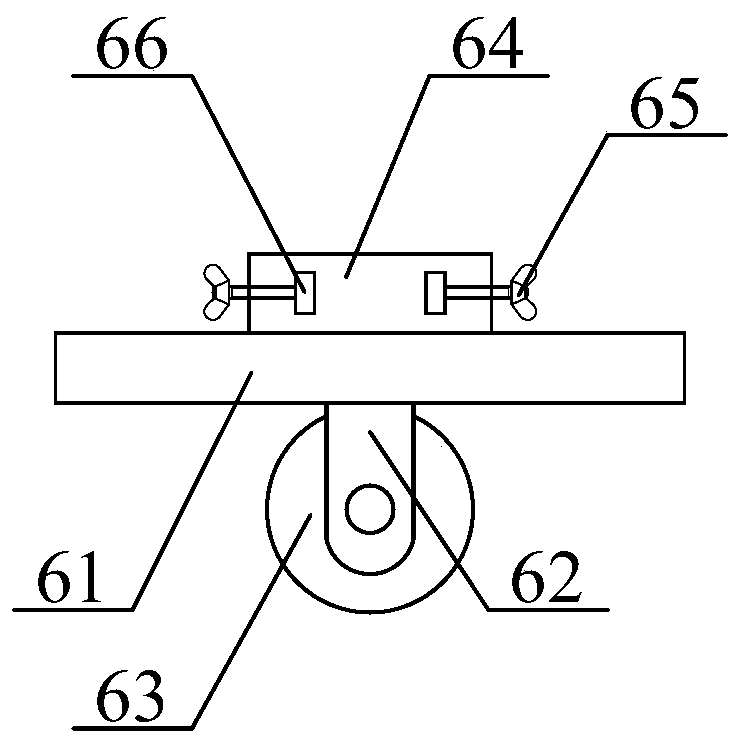

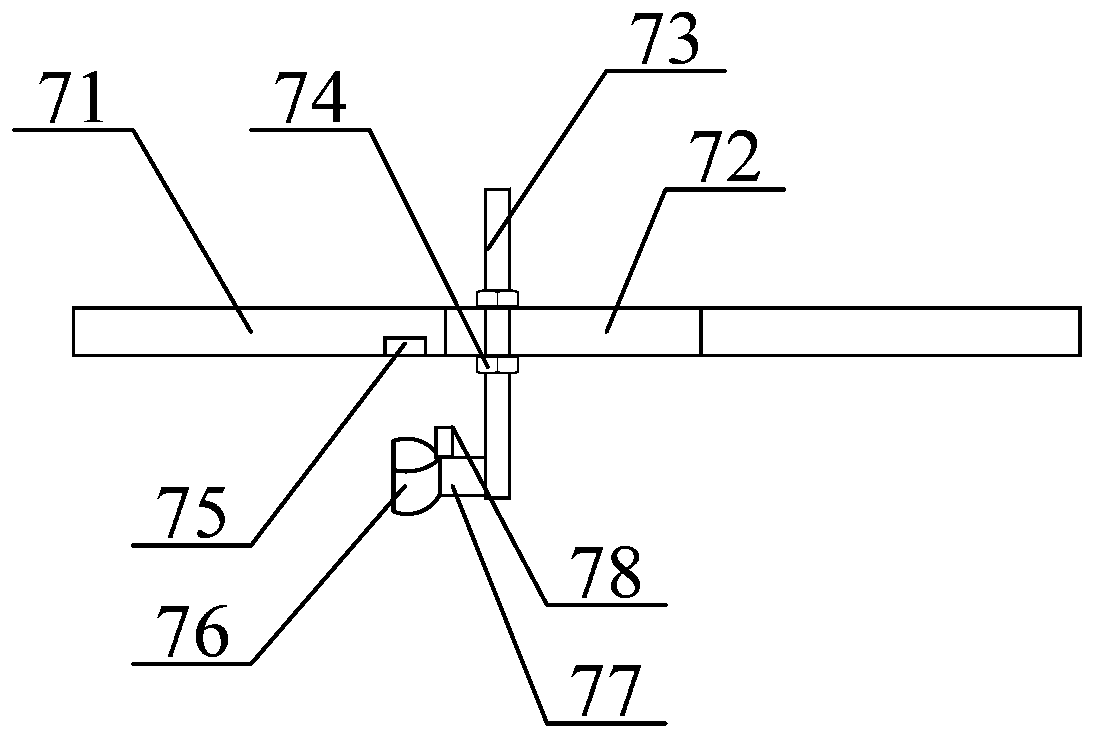

[0032] As attached figure 1 And figure 2 As shown, a new type of automobile shock absorber testing device according to the present invention includes a support plate 1, a fixed plate 2, a first connecting seat 3, a detection motor 4, a detection wheel 5, which can imitate a tire pressure wheel structure 6, The adjustable clamping seat detection board structure 7, which can support the corrosion detection box structure 8, the shielding cover 9, the rotating cover 10, the handle 11, the first support rod 12, the first sliding hole 13, and the shock absorber 14, said fixed The right side of the plate 2 is bolted to the lower part of the left middle position of the support plate 1; the first connecting seat 3 is bolted to the left side of the upper middle position of the fixed plate 2; the detection motor 4 is bolted to the first The middle position of the upper end of the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com