Mounting base structure for protecting and transferring electrical automation equipment

A technology for electrical automation and installation of bases, which is applied in the direction of electrical equipment structural parts, electrical equipment casings/cabinets/drawers, electrical components, etc. and other problems to achieve the effect of reducing the adjustment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

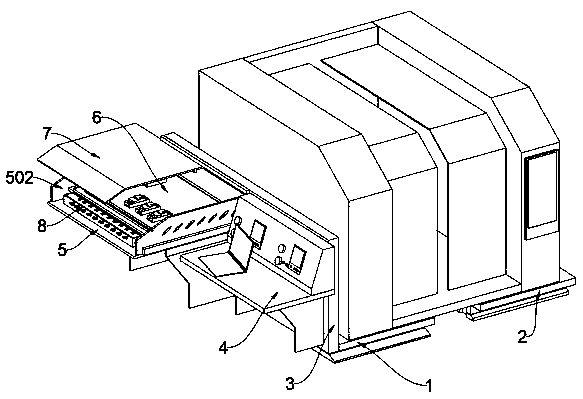

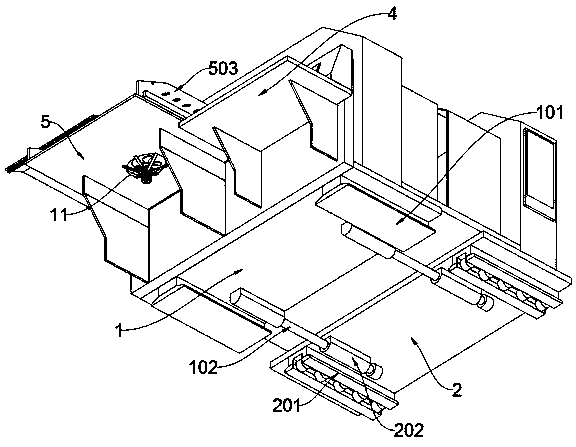

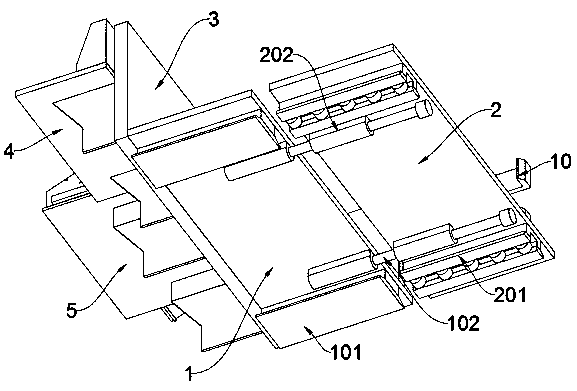

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The invention provides an installation base structure for the protection and transfer of electrical automation equipment, including a front base 1, a rear base 2, a workbench 4, a voltage stabilizing platform 5, a grid plate 6, an explosion-proof cover 7, and a wiring groove 8. Telescopic frame 9, hook bar mechanism 10, fan 11; the front of front base 1 is fixedly connected with front partition 3; rear base 2 is movably connected to the rear of front base 1; telescopic frame 9 is connected to the side of front base 1 by welding; Hook fence mechanism 10 is movably connected on telescopic frame 9, and hook fence mechanism 10 includes guide rod two 1001, positioning plate 1002 and internal tooth groove 10021, and one end on the surface of hook fence mechanism 10 is connected with guide rod two 1001 by welding, and positioning The plate 1002 is slidingly connected to the two guide rods 1001 through clearance fit; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com