Material packaging system and betel nut packaging system

A packaging system and material technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as low work efficiency, counting errors, missing packaging, etc., and achieve the effect of improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments of the description. Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the technical field of the invention. The terms used herein in the description of the present invention are for the purpose of describing specific embodiments only, and are not intended to limit the present invention. In the following description, the expression "some embodiments" refers to a subset of all possible embodiments, but it should be understood that "some embodiments" may be the same subset or a different subset of all possible embodiments. sets and can be combined with each other without conflict.

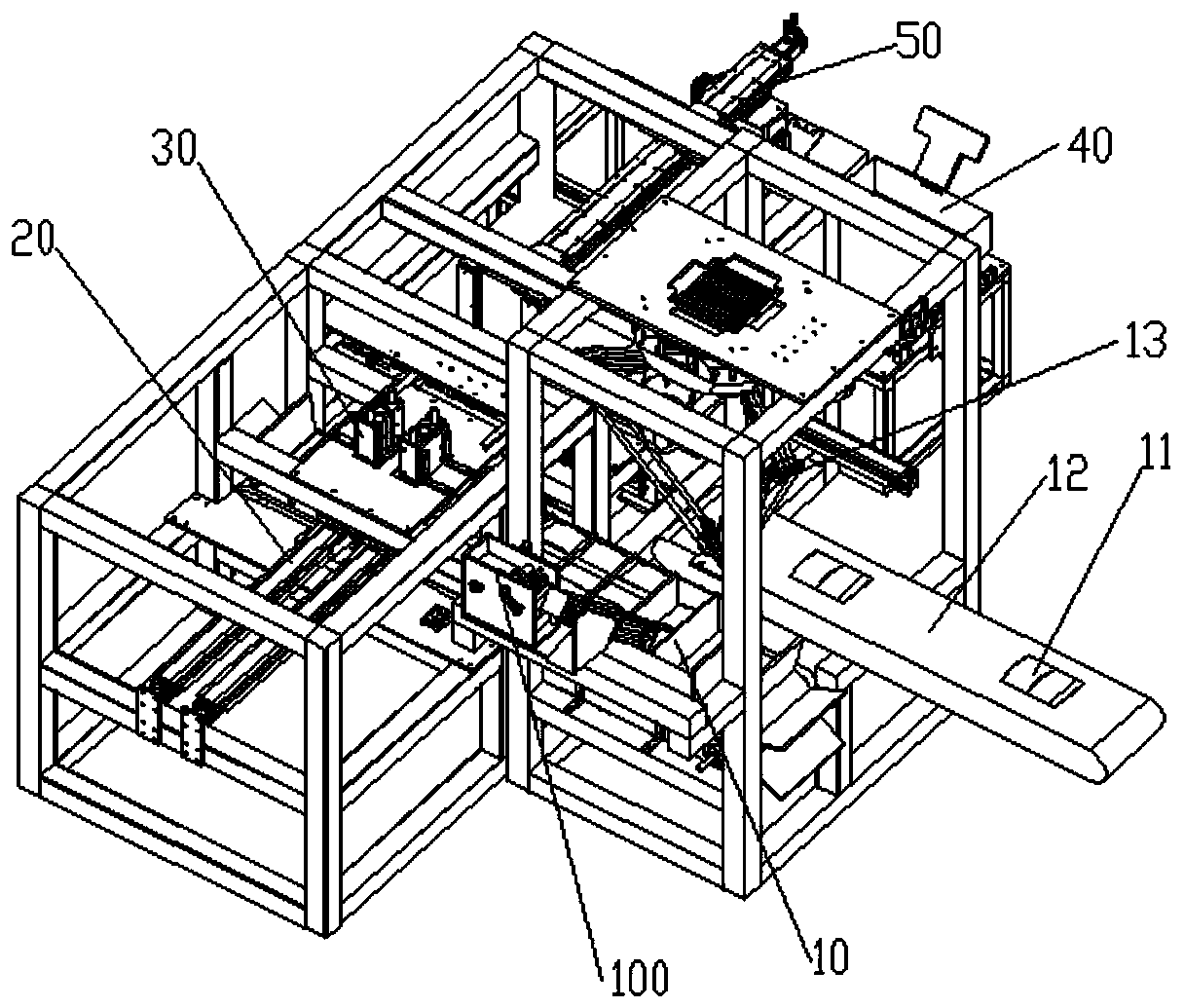

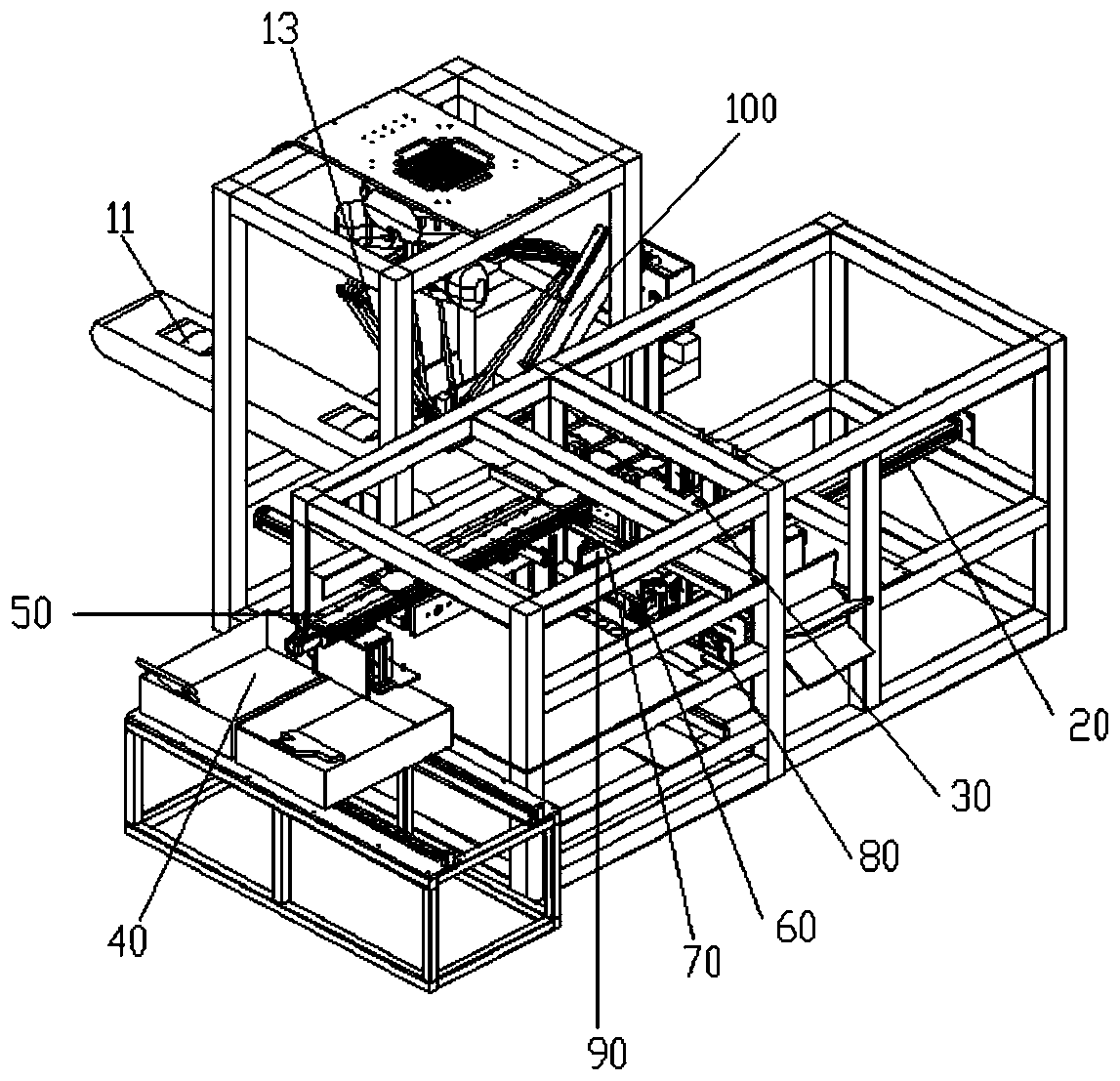

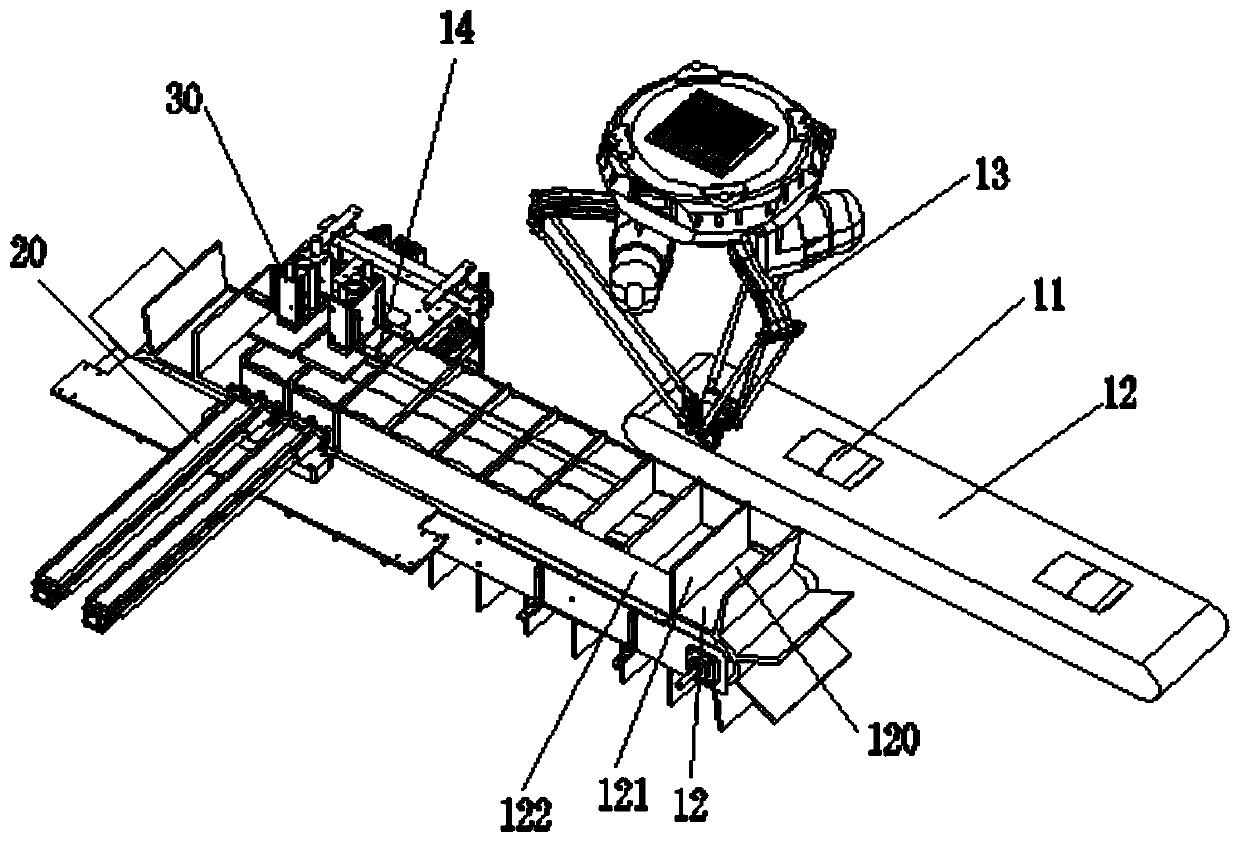

[0057] figure 1 and figure 2 Shown is a schematic structural diagram of a material packaging system provided by an embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com