A kind of cross beam in the middle of the cover plate for shock-absorbing safety cabin and its installation method

A cross beam, safe technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of waste of materials, large land occupation, high cost, and achieve the effect of reducing consumption, easy installation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

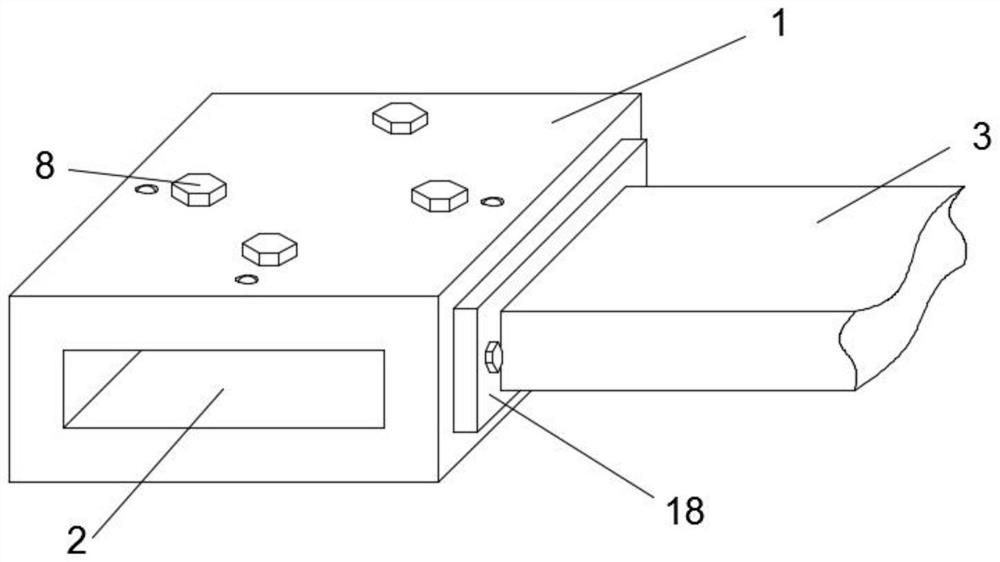

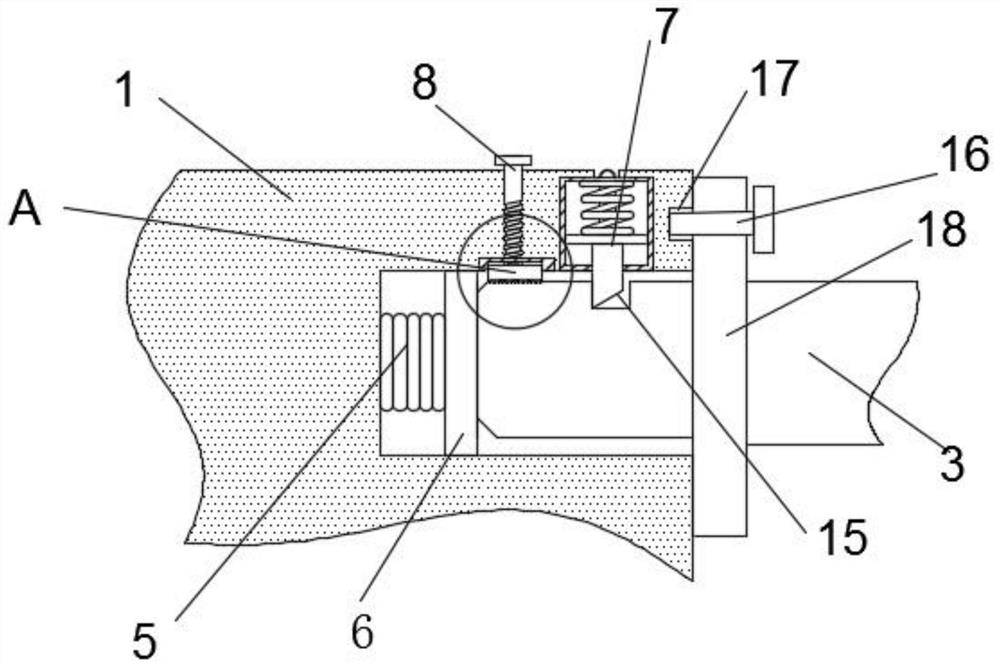

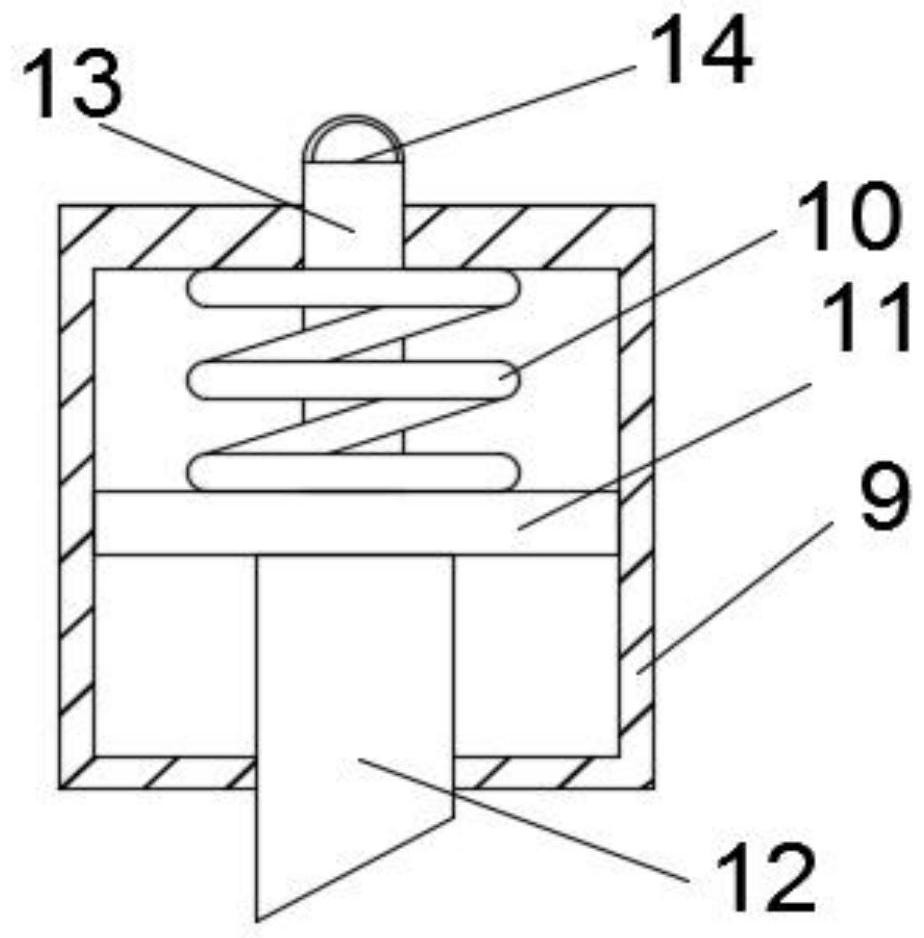

[0023] Such as Figure 1-5 As shown, the present invention provides a cross beam in the middle of a cover plate for a shock-absorbing safety warehouse, including a mounting frame 1, a mounting groove 2, a horizontal plate 3 and a limit device 7, and the side wall of the mounting frame 1 is symmetrically provided with mounting grooves 2 , the inner wall of the installation groove 2 is fixedly connected with a first spring 5, one end of the first spring 5 is fixedly connected with a push plate 6, the push plate 6 is engaged with the inner wall of the installation groove 2, and the inner wall of the installation groove 2 slides A horizontal plate 3 is connected, the outer wall of the horizontal plate 3 is fixedly sleeved with a fastening plate 18, and the top of the installation frame 1 is provided with a limiting device 7, and the limiting device 7 includes a fastening groove 9, a second spring 10, The connecting plate 11 and the limiting rod 12, the inside of the installation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com